46 |

Oilfield Technology

June

2016

can be flowed back to surface without damaging equipment, and

without handling issues associated with acid treatment waste fluid.

Fieldresults

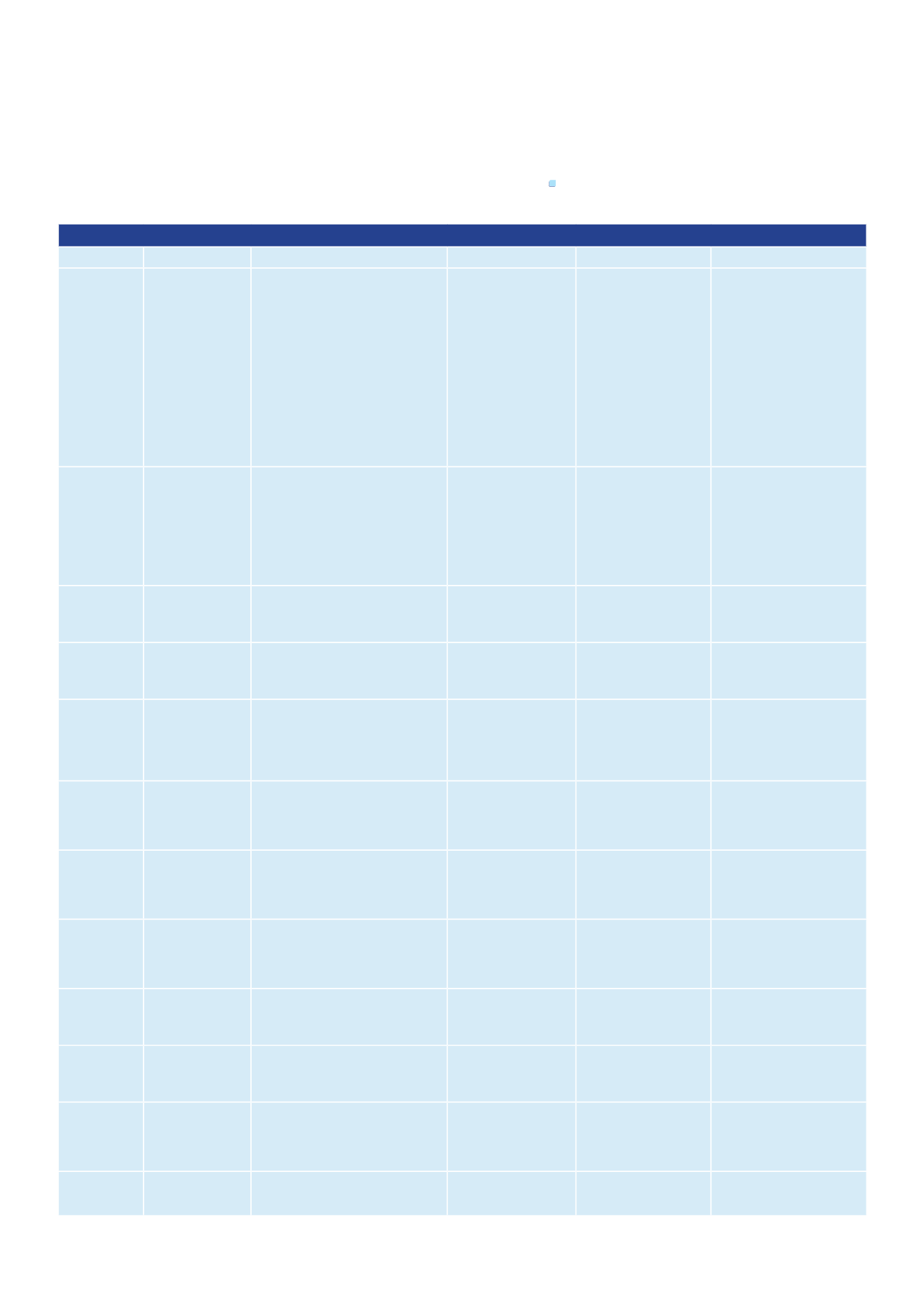

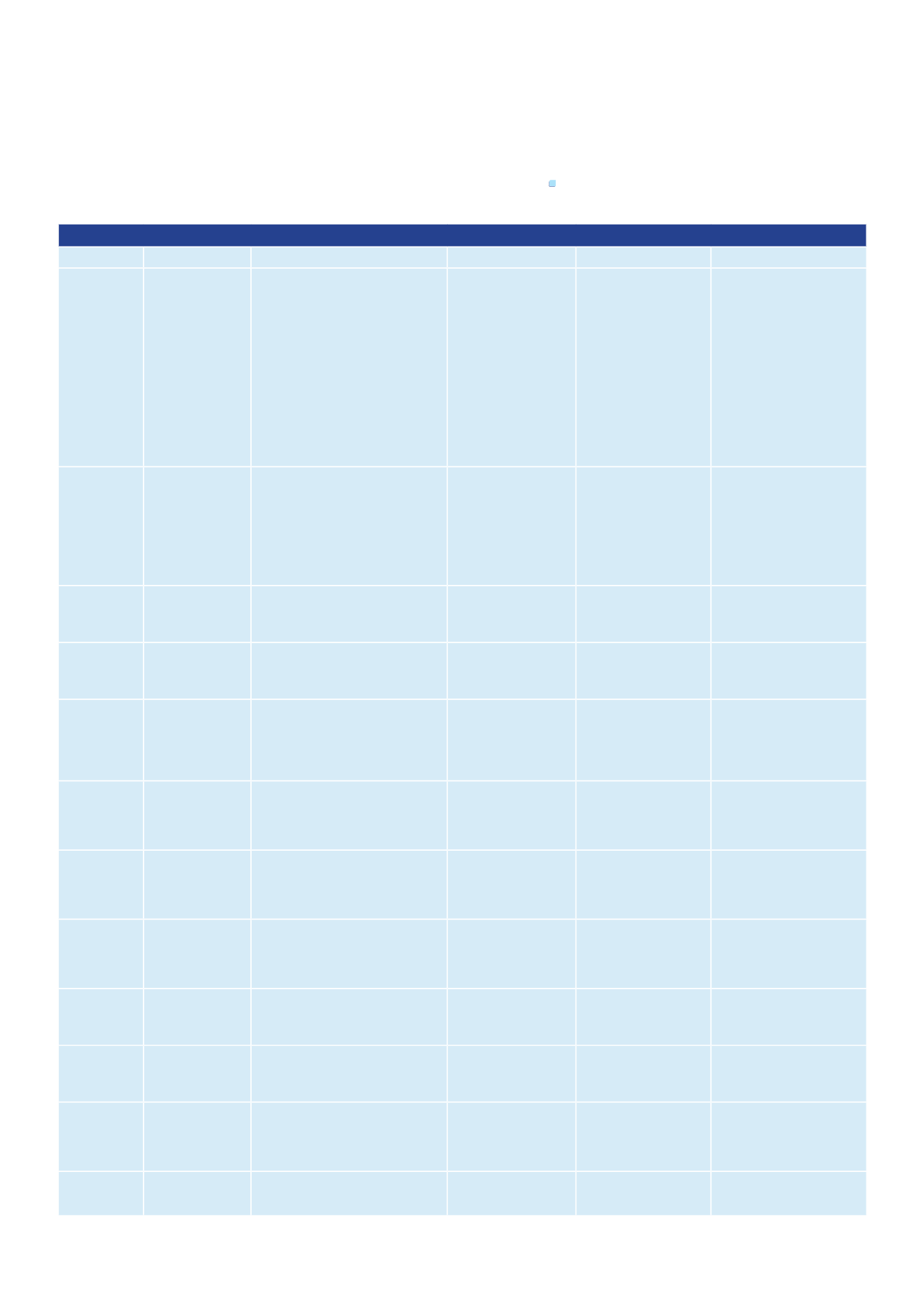

Table 1 summarises 12 examples of successful treatments using

HDC to remove barite and scale and in some cases dramatically

increasing production or injection rates. Applications in oil and gas

Table 1. HDC barite dissolver case histories.

Location

Well type

Problem

Treatment

Deployment

Results

UK North Sea

28 000 extended reach

well with perforated

liner.

Barite from OBM caused severe skin damage.

Well under-produced from the outset.

High water cut, caused barium, strontium

sulfate and carbonate scales that impaired

production.

HDC I and HDC II designed

for barite and scale.

Bullheaded, 12 hour soak.

Pre-treatment production:

1550 bpd.

2424 boe/d.

After treatment:

2245 bpd

4997 boe/d

Stabilised production:

2340 bpd

3984 boe/d

Net increase in oil production was

51%. Removed 156 kg mud-grade

barite and 50 kg of barium scale.

UK North Sea

Three horizontal wells

with ESP and 900 ft of

screens.

Dolomite/barite mud solids blocked off

screens and ESP. Problem compounded by

HCI and U104-U105 treatments to remove

carbonate scale.

Koplus LO pumped ahead of

HDC Mark II.

Bullheaded.

First HDC soak: 8 - 12 hours.

Second HDC soak: 24 hours.

First well:

Pre treatment production:

11 000 boe/d

After treatment production:

22 000 boe/d.

Two more ESP wells treated,

contributing 60 000 boe/d.

UK North Sea

New

gravel-packed injector

well, moderate

temperature of 148˚F.

Operator attempted to inject through well

without removing SBM mud cake. Injection

significantly impeded.

HDC Xream and Mark II.

Coiled tubing placement,

24 hour soak.

Removed all filter cake even at low

bottomhole temperature.

UK North Sea

Oil producer completed

with well screens,

moderate temperature

of 148˚F.

Barite from OBM blocked screen and caused

skin damage.

HDC Mark II, 4000I.

Bullheaded, cleaned up

under its own pressure after

48 hours.

Production doubled from

pre-treatment levels, attaining

theoretical 90% rate.

UK North Sea

Horizontal oil producer

with 2000 ft reservoir

section, collapsed

shale left only 400 ft

able to produce.

SBM compressed around the well screen,

barite solids drop-out in formation. No results

from prior solvent/ nanowash treatment.

Koplus LO pre-flush,

HDC Mark II with calcium

carbonate dissolver.

Bullheaded, three treatments.

PI increased from 1.5 to 7.5.

Production before treatment:

400 boe/d.

Production after treatment:

4000 boe/d.

Louisiana

HPHT gas well,

12 000 psi THP 415˚F.

Well experienced severe mud losses during

drilling, stopped by massive LCM pills.

HCI and HF/HCI treatments could not remove

damage, liquefying formation.

HDC Mark II with Koplus LO

preflus.

Squeezed into well. Two-stage

soak.

Well produced 18 million ft

3

before

metal and gravel blocked choke

and tubing. Demonstrated that

gross damage to well could be

reversed.

Malaysia

High temperature gas

well, 325˚F deviated,

dual string completion,

perforated liner.

Originally designed to produce 25 million ft

3

but only produced 10 million ft

3

. OBM was

pumped to kill well. Perforations in both

zones buried in settled barite. Acid treatment

left well producing only 1 million ft

3

.

HDC Mark II, bullheaded

through short string.

Bullheaded through short

string. 26 hour soak. CTU used

for N

2

gas lift.

Production increased to

7 million ft

3

/d and 5 m

3

/d

condensate and 1228 kg of barite

dissolved.

Malaysia

High temperature gas

well, 325˚F deviated,

dual string completion,

perforated liner.

Originally designed to produce 50 million ft

3/

d

but only made 20 million ft

3

. Well impaired by

settled OBM solids. During a CT acid-washing

job, a jetting head was lost and production

rates remained poor.

HDC Mark II after Koplus LO

and Super Pickle pre-flush.

Bullheaded into lower zone.

The well recovered under its own

pressure and was placed on stream

at 45 million ft

3

.

Thailand

Monobore newly

drilled injector with

perforated liner.

Drilled with OBM, the well failed to inject after

perforation, blocked with barite.

HDC Mark II, in two stages.

Placed with coiled tubing unit,

first soak eight hours, second

soak 24 hours. Gas lifted

with CTU.

Well went operational injecting

8500 boe/d at 1500 psi.

Nigeria

Horizontal well

with 2467 ft section

completed with open

hole slotted liner.

Well had no production due to OBM solids and

damage from poor acid job. Two attempts

failed to unload well.

Super Pickle/Koplus LO pill

followed by HDC Mark II.

Coiled tubing placement.

Soaked for 24 hours. N

2

used

to lift well.

Well flowed at 2700 bpd at 650 psi

and stabilised at 2500 bpd.

Nigeria

Newly drilled producer

with well screens in

open hole. 160˚F BHT.

Well initially shut in for 152 days because of

local unrest, then produced poorly. Formation

impaired with mud solids. Fish left in well

during stimulation attempt, resulting in no

production.

Koplus LO and Super Pickle

pre-flush followed by HDC

Mark II.

Coiled tubing run to top of

fish, then treatment was

bullheaded.

Production increased from 0 bpd

to 3000 bpd.

Australia

HPHT geothermal well,

vertical.

Fish lodged in settled barite and through

milled bridge plug.

HDC Mark II, spotted three

times.

Bullheaded.

Fish, released from barite, fell to

bottom of well. No further fishing or

milling required.

fields around the world have included extended reach offshore

wells with severe oil based mud skin damage, horizontal wells

with clogged screens and electrical submersible pumps, injector

wells clogged with barite, and high temperature gas wells whose

production was impaired by mud filter cake and scale. In these

cases, HDC has been a practical solution for dealing with barite

problems.