40 |

Oilfield Technology

June

2016

wire that was required to extend through the third party tool.

Although cumbersome and to some degree limiting the tools

which could be run, it was essential for communicating with the

portion of the tool responsible for controlling the orientation the

tool moved in. Later, after further testing, a ‘wireless’ version of

the tool was produced. The wireless iteration includes a wireless

sub that allows communication to the steering section of the

tool without requiring modifications to the third-party tool. This

increased the overall flexibility of the tool and widens the range

of applications for the operator.

Tool hardware

Well hardwarescanner (WHS)

Within a well completion the metallic components such as casing

collars, perforation holes and sliding sleeves, create varying

fluctuations in any electromagnetic field which is induced

around them. The WHS monitors these magnetic variations

very precisely to determine where exactly in the completion

the toolstring is located and, more to the point, where the

entrances to lateral windows are located. The WHS does this

with a number of magnets and magnetic sensors placed in a

grid pattern. Sensors then measure the magnetic field’s angle

in relation to the tool’s axis. The tool’s geometry relative to

the surrounding casing material creates anomalies in the

magnetic field. This information provides depth measurement,

lateral window identification, lateral entry confirmation, tool

speed and direction, and distinction between openhole (OH)

and cased-hole (CH) environments. The tool also incorporates

an accelerometer for inclination data. Figure 3 shows a

representative WHS log over a CH lateral junction. The wide

spacing, very low signal strength correlates to a junction where a

lateral exits the main wellbore.

Well ultrasonicscanner (WUS)

The WUS uses transducers and range-finding principles of

time-of-flight measurement for ultrasonic signals to determine

the casing environment. Ultrasonic transducers face outward

from the outer diameter of the tool. These transmit signals

sequentially while the transducers monitor the echo return time

and amplitude response of the signals. This tool also incorporates

an accelerometer for inclination. Figure 4 shows a graphic

representation of the transducer signal emitting from the tool.

The transducers map the inside diameter of the wall opposite

of the tool, thereby identifying the surrounding wellbore

environment. Software located on the surface interprets the

signals sent and received by the WUS to determine spots of

diverging radius. This information identifies areas like washouts

or sidetracks, for example. The WUS provides lateral window

identification, lateral entry confirmation, orientation and the

distinction between OH and CH environments. Figure 5 shows a

comparison of multiple passes in the mainbore and two different

laterals mapped by the WUS.

Wireless sub

The wireless sub enables communication with the steering joint

of the multilateral intervention tool wirelessly. This eliminates

the need for 3

rd

party tools to be thru-wired, thus increasing the

flexibility of what can be run in combination with the multilateral

intervention tool. The wireless sub contains batteries for 12-hours

to activate and steer the joint from surface in response to the tool

outputs.

Electromechanical actuator–steeringaccesssub(SAS)

The SAS uses the information obtained from the sensors and

known wall-path reference points to maneuver into the various

laterals. This maneuver is completed in two steps. First, the

steering joint pivots around its central axis towards the direction

of the centre of the lateral. Next, the hydraulic piston in the SAS,

controlled from surface, can orient the joint in any direction in

15˚increments.

Fieldtrials

The multilateral intervention tool went through a number of field

trials on wells in Saudi Arabia entering many different wellbore

types; some had been completed with a CH main bore and

OH laterals while others had been completed with an OH main

bore and OH laterals. These field trials proved the tool’s sensor

ability to accurately scan the main bore at the depths required.

The sensors were able to identify the position, depth and direction

of the lateral window and guide the bottom hole assembly (BHA)

into the required lateral in the wellbore. Additionally, the field

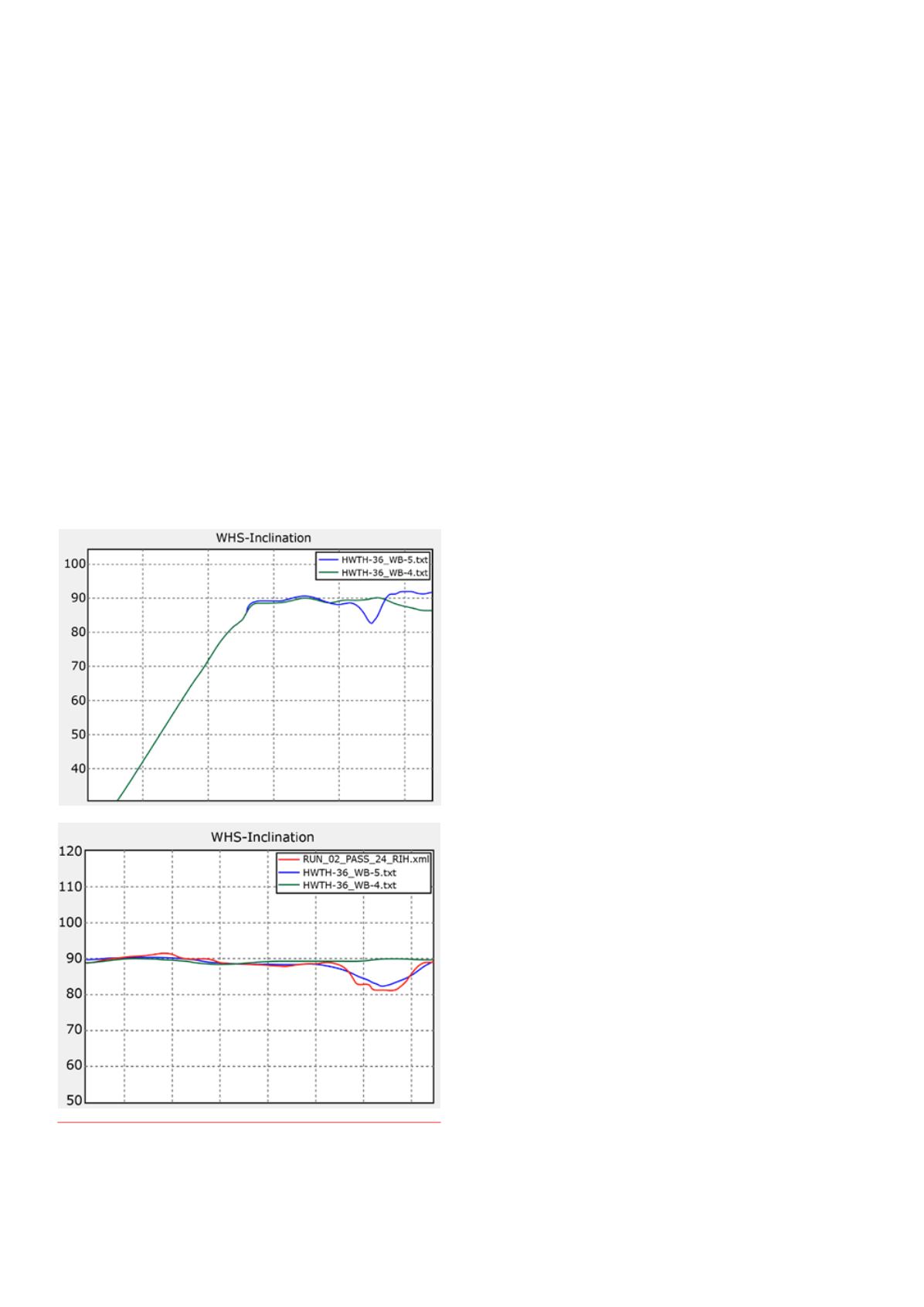

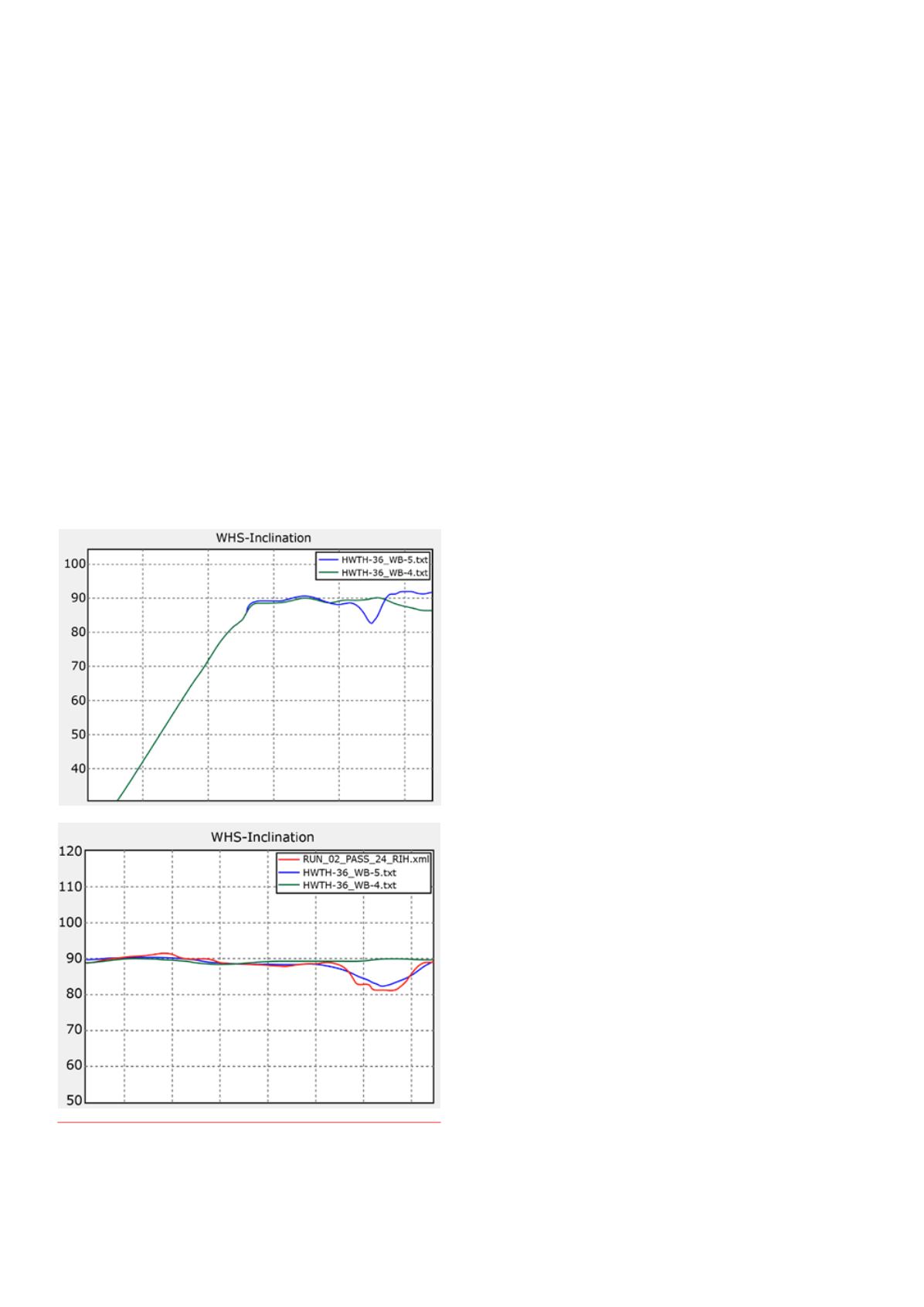

Figure 6.

Graphs showing readouts fromtheWHS for a lateral.

Inclinationanddepthwere recordedandused to locatewhich lateral the

tool was entering in thewellbore.