June

2016

Oilfield Technology

|

49

Fractureandproductionmodelling -

ThreeForks

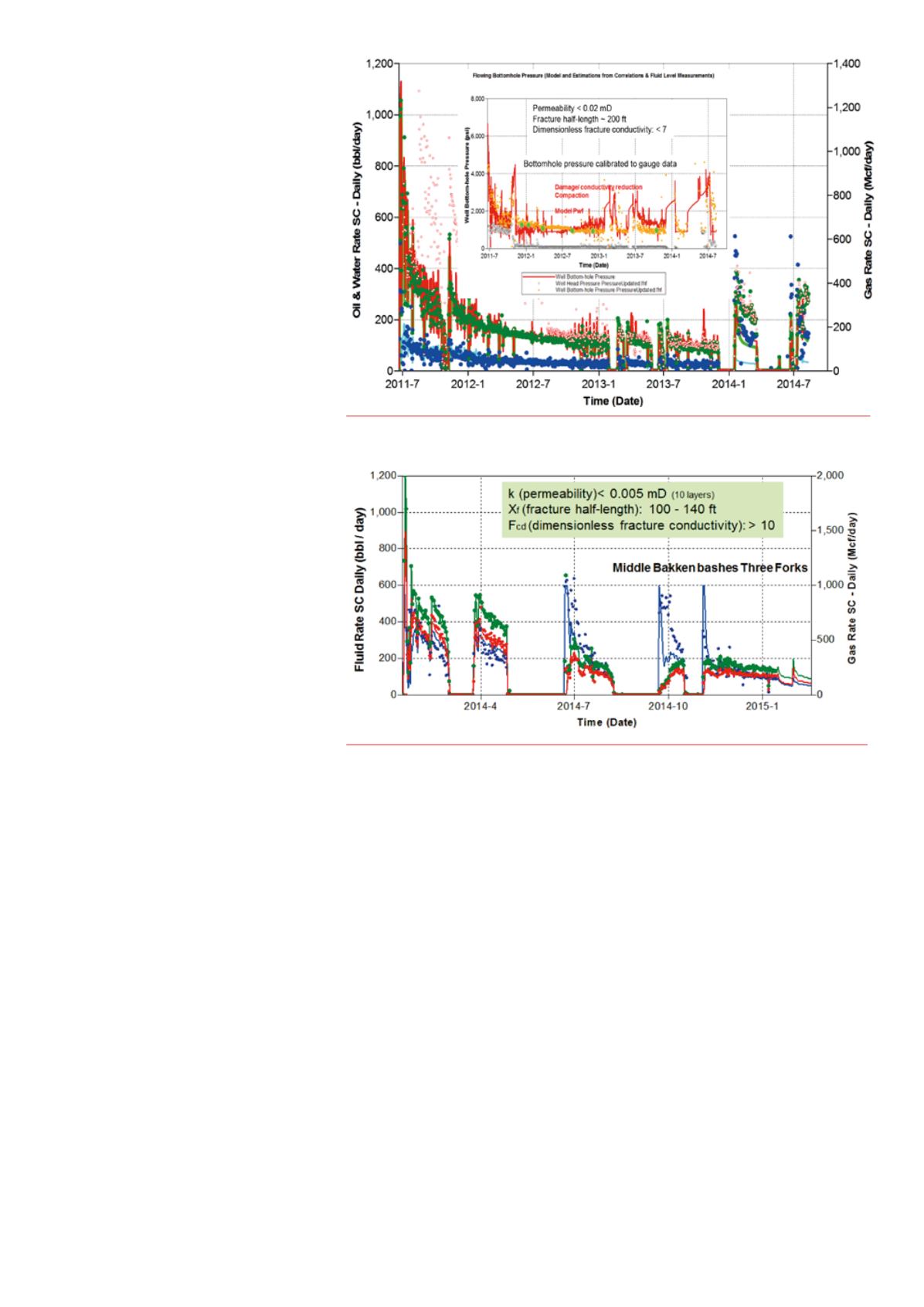

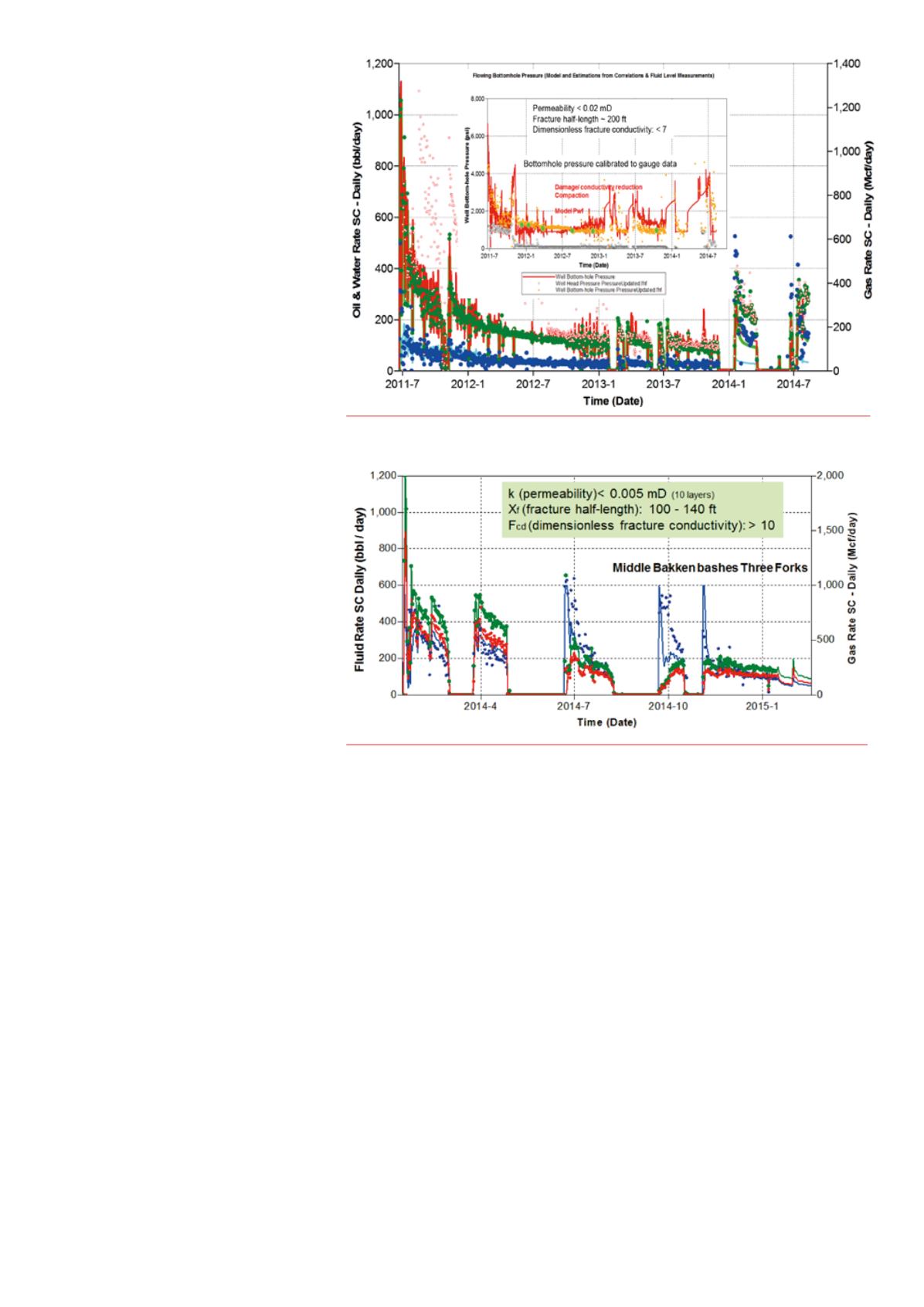

Fracture modelling in the Three Forks indicated

that the SS treatments connected into the

Middle Bakken due to the creation of a large

single dominant fracture. Production modelling

confirmed that the connection to the Middle

Bakken was stress sensitive and deteriorated

within the first three months of production

(Figure 4). Flowing bottomhole pressure and

water cut indicated that this well was connected

to the Middle Bakken for a significantly longer

time than expected (Aman, 2010). The SS

Three Forks well had a permeability less than

0.005 mD (top 10 layers of the Three Forks),

fracture half-lengths ranging from 100 - 150 ft.

and a dimensionless conductivity greater than

10 (Figure 4). The short fracture half-lengths

observed were consistent with fracture

modelling. In the PnP Three Forks treatments,

connectivity to the Middle Bakken was poor due

to the addition of multiple clusters per stage (via

PnP) and subsequent reduction in job volume per

fracture propagating in a stage.

Optimisationwithnoparentwell

influence

Once the multi-domain iteration was complete

and models with quantified uncertainty ranges

built, predictive modelling could begin. For

the fracture length and number of stages to be

optimised, the bounding (offset) wells were used

to ensure accurate forecasting on long-term

performance of the middle well.

Forward modelling (optimisation) runs

indicated that a hybrid cluster approach could

be utilised to maximise fracture propagation

success. Optimal job size volumes, fracture

treatment rates and stage count were determined

for the Middle Bakken and Three Forks.

The results indicate that the maximum production is obtained by

increasing the number of fractures in a well from X to 4X. Thus, if a SS

completion systemwas utilised, 4X sleeves with entry-points must

be installed. If a PnP approach is utilised, fracture modelling has

demonstrated the pump rate required to propagate two to five clusters

and the resulting job size requirements.

3

Optimisation also shows

that past 4X fractures, further production uplift can be achieved from

increased fracture length (deployment of modified job design).

Bakkensystemin-fillwell/depletionmodelling

The in-fill interference of a parent Middle Bakken well (by an

offset Middle Bakken well) was fracture modelled and production

matched (Figure 3). Production matching of the in-fill drilling and

interference of this parent well (by an offset well) confirmed that

scale was the damage mechanism since a post-interference match

was re-established once this ‘additional damage’ was removed. This

observation and the scale treatment history of this well resulted

in the hypothesis that the relatively fresh water from the fracture

treatments dissolved the scale in the parent well. Numerous cases of

in-fill interference have been reported in the basin over the past few

years. To date the impacts of interference on the parent well have been

primarily related to additional ‘stimulation’. Modelling results indicate

that it is unlikely to have sufficient amounts of proppant to travel those

distances even under asymmetrical conditions. Thus, scale dissolution

may also be contributing to the sustained production enhancement of

the parent wells.

As a result of poor productivity in the Three Forks interval,

minor fracture asymmetry was observed from the in-fill well. This

is due to the poor productivity of the Three Forks interval in the

area. However, interference is caused from an upper reservoir

(Middle Bakken). To date little research has been performed to

understand the productivity and the extent of depletion in the Upper

and Lower Bakken Shale.

As production reduces stress but increases effective stress it

can be expected that simultaneous fracture operations (driving

efficiency) are created to form a similar asymmetry and lack of

increased containment. Completing Middle Bakken wells, followed

immediately/shortly by an in-fill Three-Forks will result in containment.

EagleFordsystemparentwellmodelling

Workflows and procedures for the characterisation and testing

(calibration requirements) of rocks that are both the source rock and

reservoir have evolved significantly from those used in conventional

plays. Since, pressure, permeability and saturation are much more

challenging to measure in thin-bedded unconventional reservoirs using

Figure 4.

Pressure andproduction historymatch – the effect of bashing notedat the end of history.

Figure 3.

Pressure andproduction historymatch – the effect of bashing notedat the end of history.