June

2016

Oilfield Technology

|

39

can be computed. This insight can then be capitalised upon to

aid in well optimisation, reservoir production and overall field

management.

Staying ahead of the curve, Saudi Aramco has been investing

heavily in a strategy for maximum reservoir connectivity or MRC.

The Haradh III development, completed in 2006, demonstrated the

success which could be achieved with extended reach, horizontal,

multilateral wells.

3

As a part of that strategy they would need to

be able to gather production data in multilaterals to illuminate

their decision making process; production data incorporated

into reservoir modeling incorporated into field management.

Many of these wells were fitted with sensors and controls to allow

monitoring and corrective action, providing important data to

fulfill the objectives outlined previously.

Notwithout challenges

But what about multilaterals wells that had been drilled prior

to this or in other fields? What about wells where the economics

were not conducive to a fully automated approach? Until recently

there was no effective or efficient way to successfully enter the

multilateral sections of wells with PLTs. Run on electric line

(e-line) or slickline, the challenges were that the tools could

not ‘see’ where the lateral junctions were nor could they orient

themselves such that they would move out of the mainbore

and into the lateral. This was compounded even further by the

increased application of highly deviated and horizontal wellbores.

Coiled tubing (CT) could convey PLTs into the wells but could not

effectively guarantee orientation into the lateral section. One

service provider did develop a mechanical, bottom orientation

sub to locate and access laterals, but the tools that could be run in

combination with it were limited.

4

Again, Saudi Aramco remained firmly ahead of the curve in

overcoming this challenge. Recognising the need to add laterals

to existing wells for increased production and to assess the

laterals in already existing wells, the EXPEC Advanced Research

Centre Production Technology Team, in partnership with Welltec,

in 2008 began to consider the challenges of entering laterals

in order to take measurements.

5

The objective was to develop

a multilateral intervention tool that could be used to reliably

access and gather data from the various multilaterals, aiding to

further illuminate operators’ well, field and reservoir strategies.

Themultilateral interventiontool

The multilateral intervention tool is built on an electromechanical

platform that merges a sophisticated sensor package with an

actuator system to detect and selectively enter laterals with e-line

tools. Figure 2, shows a schematic of the 2 ⅛ in. OD, toolstring. It is

comprised of a number of discrete components, as shown, which

are detailed further below. One of the critical design elements was

the capability of the tool to be able to work in combination with

as many other tools as possible, thus ensuring wide versatility of

the data which could be acquired during the lateral intervention.

Hence the multilateral intervention tool can be run with any e-line

company and convey their technology into the lateral section(s).

Development

The multilateral intervention tool went through a number of

versions and trials before the final version was produced. Early

versions of the tool were ‘wired,’ incorporating a feed-through

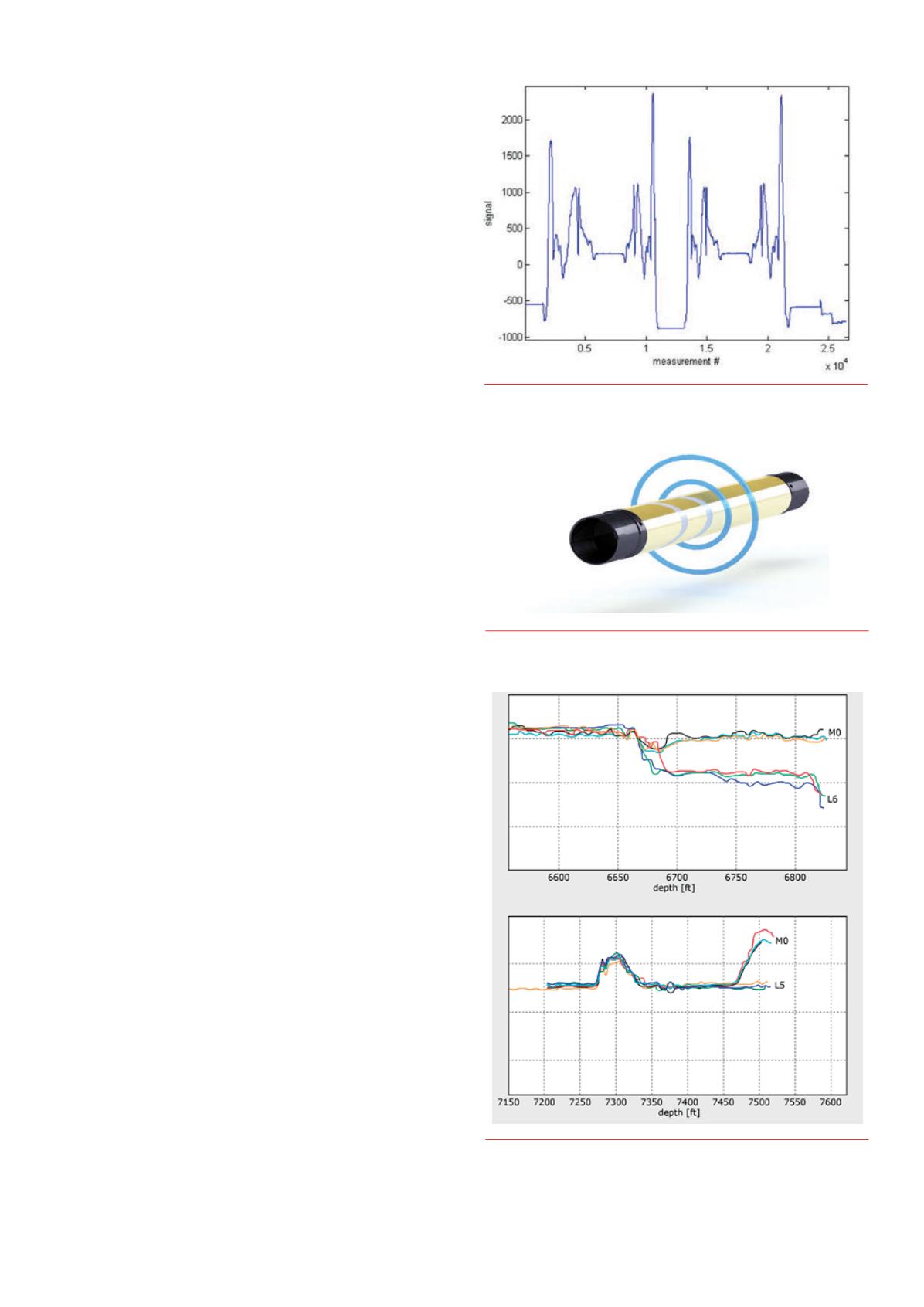

Figure 3.

WHS log over aCH junction.

Figure 5.

Comparison ofmainbore and two lateralsmappedbyWUS -

(A) top, and (B) bottom.

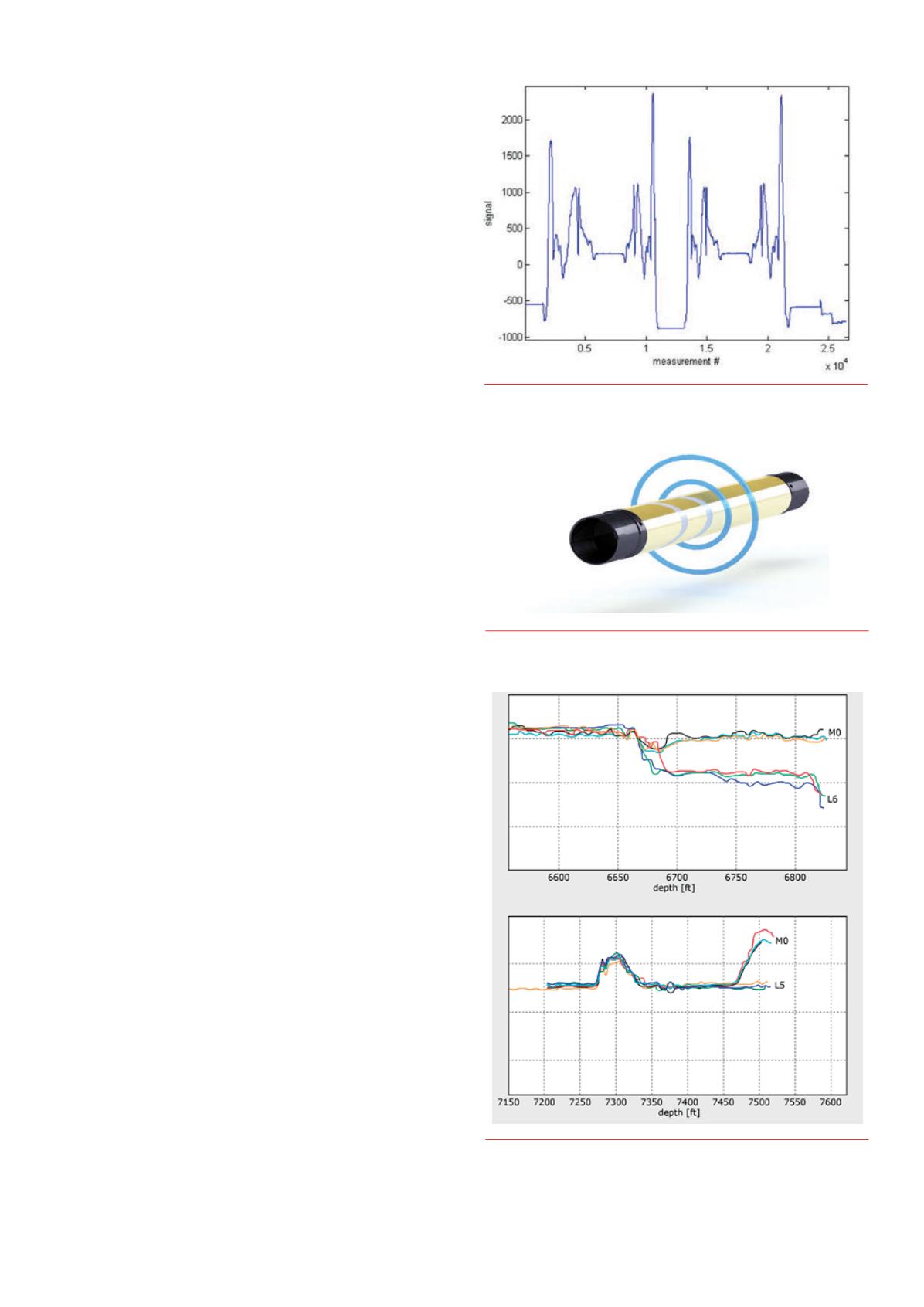

Figure 4.

Graphic representation of theWUS.