28 |

Oilfield Technology

June

2016

a significant investment of engineering resources and capital.

And once created, such a bespoke asset should not be blindly

force fit into an improper application to the detriment of

another operator. The only long-term path over such hurdles

for service companies is to jointly commit to focus first on

performance for the customer.

Reducingvibrations, reducingtool

failures

Reducing vibration is particularly important

in wells that utilise RSS, which are

becoming more popular as well planners

are pushing the limits on directional

difficulty and lateral lengths. Most RSS

tools are highly susceptible to failure due to

vibration, which is one of the most common

reasons the BHA must be tripped. RSS

directional hands will often monitor these

vibrations and are forced to reduce drilling

parameters, and sometimes stop drilling

altogether to pick up off bottom when

vibrations get too high. Vibrations in a way

act as an ROP ceiling, limiting the driller to

lower parameters than what is necessary for

maximum ROP.

Ulterra’s CounterForce® technology uses

the cutting structure to reduce vibrations

at the bit, which increases efficiency and

reduces bit damage. With the ability of

the cutting structure to reduce vibrations,

operators can not only reduce the number of

trips for tool failures, but can also effectively

elevate the ROP ceiling so that they can drill

faster and still avoid high vibrations.

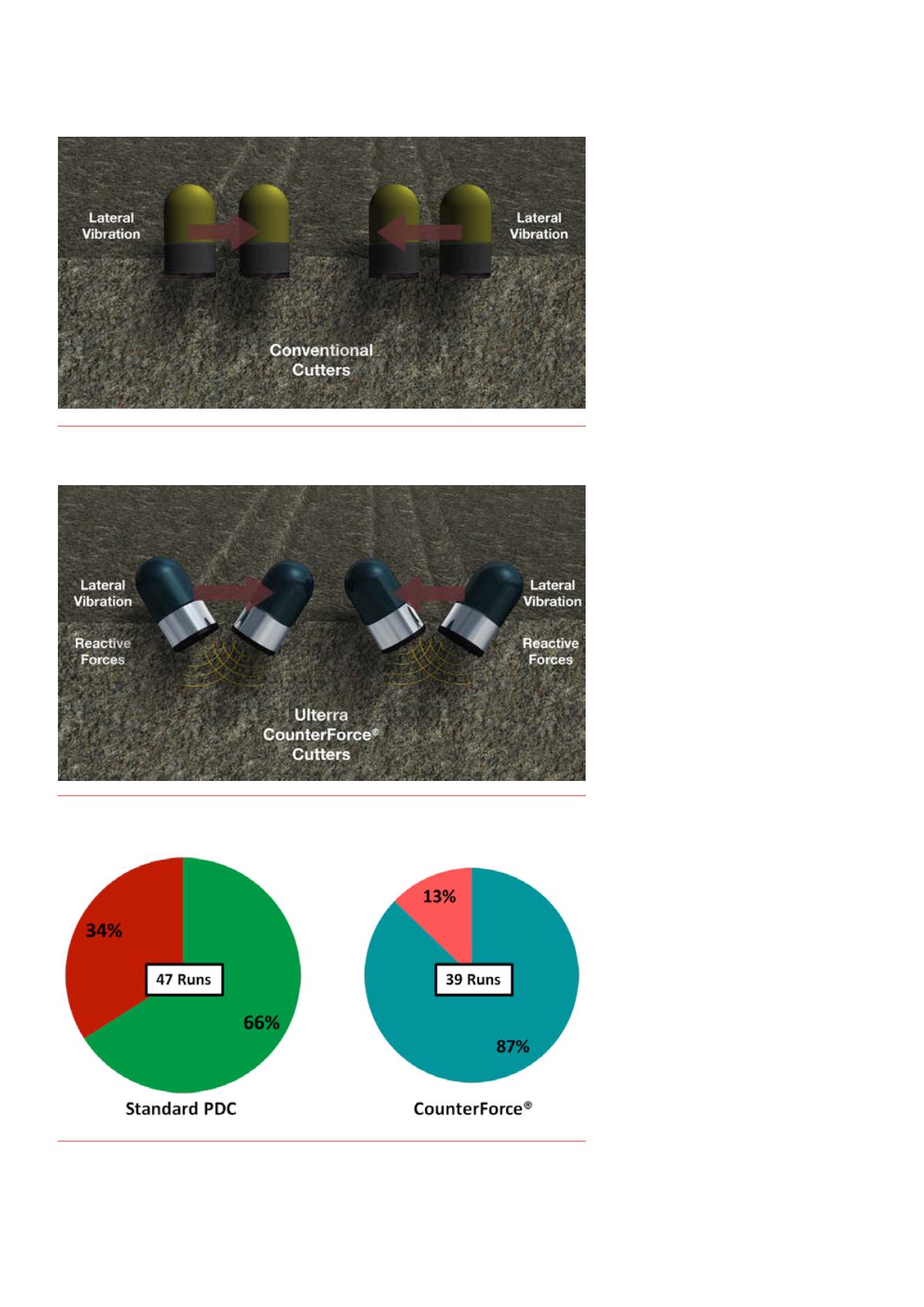

The claim that CounterForce can reduce

vibrations, and therefore increase ROP

and reduce the number of trips has been

validated through numerous field runs.

A major operator in South Texas utilises

the Weatherford Revolution RSS to drill

out from under surface through the curve

and lateral to TD in one trip. Comparing

the U516M verses alternative bits in this

application in the years 2014 and 2015, the

U516M on average drilled 7% faster. More

importantly, RSS runs with standard PDC

bits of any manufacturer were nearly three

times as likely to be pulled for tool failure

(Figure 3). The U516M completed 39 runs

within this time frame.

The technology’s performance has also

been validated through electronic drilling

recorder (EDR) analysis. A four well pad in

South Texas, again utilising the Weatherford

Revolution RSS, ran the U516M on three

wells, and a competitor bit on the fourth.

The stick-slip magnitude, measured in a

rotational value of c/min, was 35% lower

for the average of the three CounterForce

runs compared to the offset. In addition,

the average ROP for the three CounterForce

runs was 27% faster than the offset, saving

the operator 13 hours on each well the

U516M was in the hole.

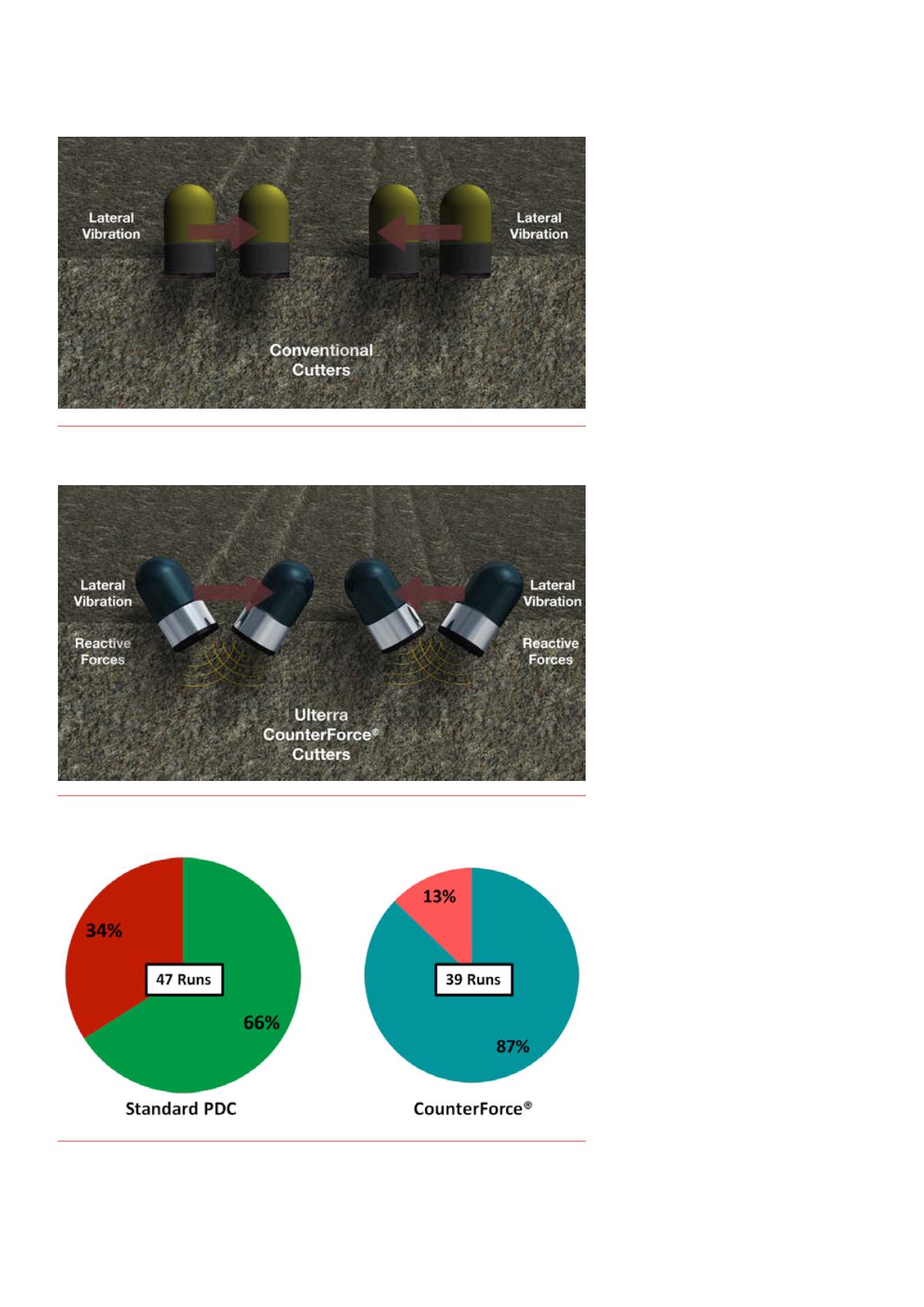

Figure 1.

Traditional PDC cutting structures are laid out to be balanced, or neutral to drilling

vibrations.

Figure 2.

The cutting structures are engineered to take anactive role indamping harmful drilling

vibrations.

Figure 3.

The percentage of RSS runs pulled for downhole tool failure. Rotary Steerable tool

reliability has positively correlatedwith the use of CounterForce bit technology over a statistically

significant data set.