visual and audible signals, ensuring that he/she is aware at all

times of the state of the load and what can be safely lifted. The

system provides an accurate calculation and display of the ‘safe

working load’, which is calculated as 85% of the machine’s rated

tipping load (ISO8813), thereby providing an additional margin of

safety. It also displays the actual load on the hook.

The LMS monitor graphically displays all information required

by the operator on the state of his load and also utilises a series

of lights moving from green to red, when the safe working load

is reached. These lights are mirrored on the external boom-

mounted light bars, which communicate to other operators on

the line, but especially to the lowering-in foreman.

On the Greek project, pipelayer

operator Panagiotis Sotiropoulos was

quick to see the benefit. “The LMS

is a fantastic help in the lowering-in

application. As an operator you can

see the work loads of all the other

machines, thanks to a system of lights

mounted on both sides of the boom

and if one machine is overloaded you

can see that and help. This makes the

whole work process much safer and

easier for the lowering-in foreman and

the operators.”

A choice of single, double or triple

grouser shoes is available depending on

underfoot conditions, although when

it gets really tough, single grousers

provide just the right grip and traction

to keep them moving.

All-round safety

To assure safety for personnel on the

ground – whether pedestrian or in any

vehicles moving along the right-of-way

(ROW) – both rear and side-mounted

cameras are fitted.

On the large, in-cab monitor, the operator can select to view

the camera images either separately or, with a split screen, both

images simultaneously. This additional reassurance only serves to

underline the importance of site safety.

As travel speed is not an issue in lowering-in, Volvo

pipelayers can and do work equally well alongside conventional

sidebooms or most likely in soft, sandy conditions, crawler

cranes, or sometimes both. This was the case with Italian pipeline

contractor Ghizzoni working on the Bunde-Etzel 48 in. gas

pipeline in northern Germany. The green lights of the LMS on the

Volvo pipelayers are clearly visibile, showing their ease with the

load.

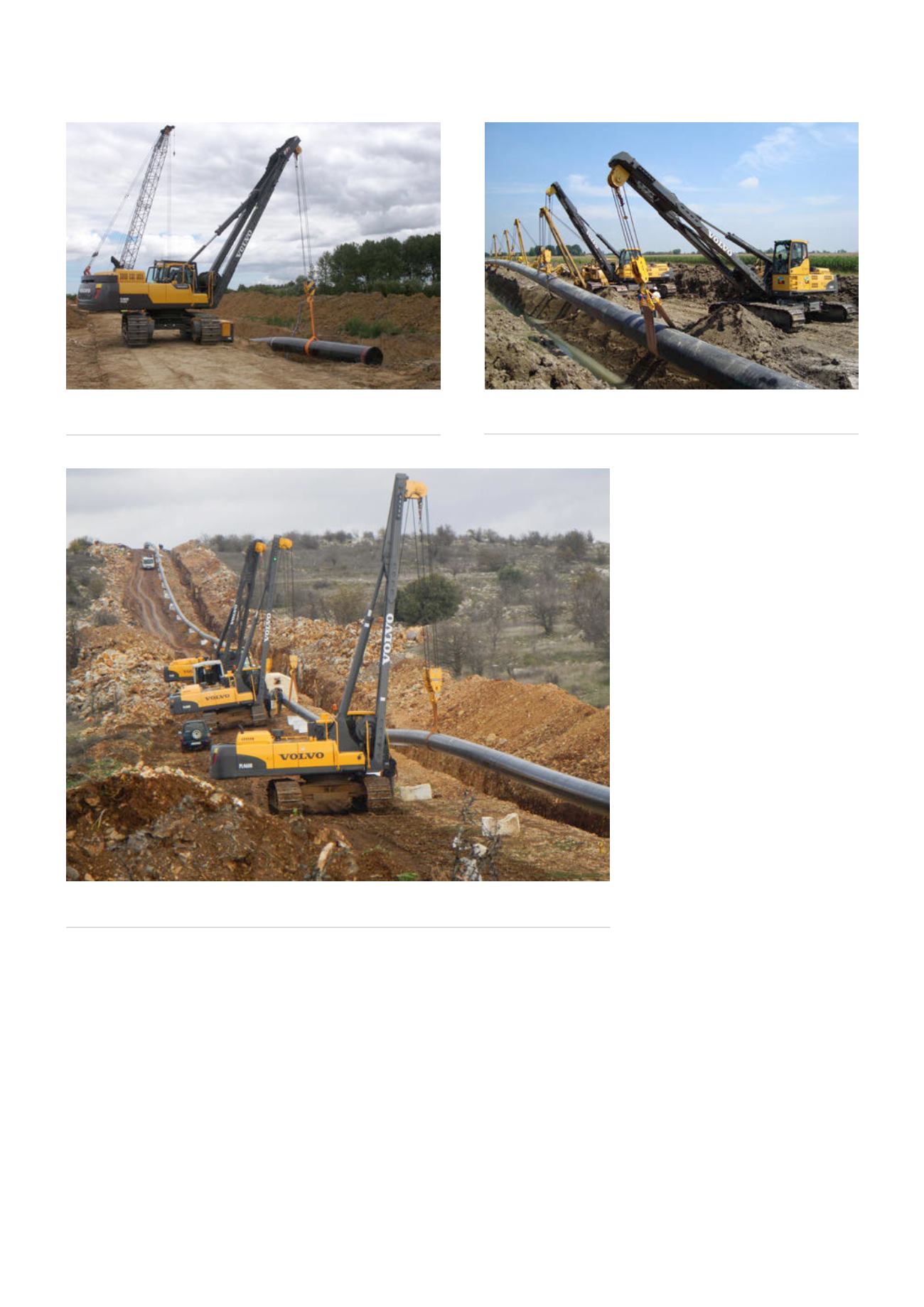

Figure 5.

Lowering-in alongside crawler cranes in soft, sandy

conditions: L’artère des Flandres in northern France.

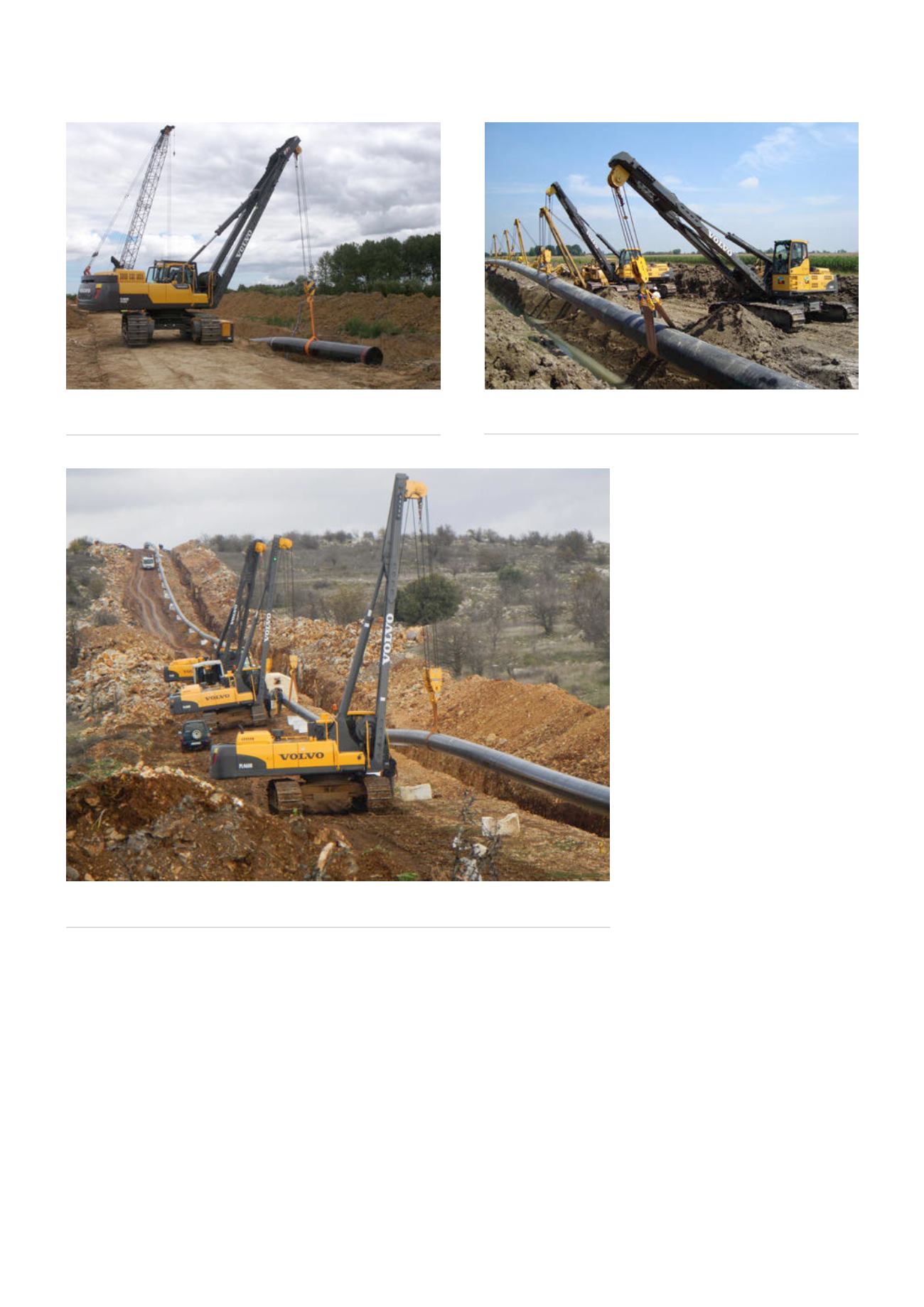

Figure 7.

Lowering-in alongside sidebooms on a project close

to Parma, Italy.

Figure 6.

Rough terrain, rocks and slopes; when the going gets tough, the tough PL4608s

get going.

102

World Pipelines

/

FEBRUARY 2016