pigging records, and pig trap designs to name but a few. Once

all this information has been collated, it will provide a good

understanding of the pipeline configuration and hopefully give

you that warm fuzzy feeling that the pipeline can be pigged by

conventional free-swimming pigs.

If areas of this data are missing – which can sometimes be

the case in countries affected by war, terrorism or simply by

bad management of data – the second part of the planning

process (the site visit) can help identify any missing pieces.

Site visit

Now, I have lost count of the number of times I’ve been on

a pigging compound in my career, however the site visit is

a critical step in the process of assuring the line is or is not

piggable. Visiting the site is applicable not only for maintenance

pigging but also for inspection purposes, both of which can

have a different set of requirements. During the site visit the

engineer will need to check the pig trap dimensions, assuming

launch and receive traps are fitted with measurements and

notes recorded in relation to the following items:

)

)

Offtakes – especially back-to-back offtakes that could

stall a pig.

)

)

Kicker lines – used to launch the pig, are they sufficient in

diameter?

)

)

Bridle pipework – can the pressure be equalised either

side of the pig?

)

)

Pig signalling devices – intrusive type, when were they last

serviced?

)

)

Types of reducer – concentric or eccentric?

)

)

Valve configurations – are they set up for pigging?

)

)

Door mechanism type – when was it last serviced?

)

)

Does the pig trap have any internal fittings – slip trays to

aid pig loading, receive baskets for foam pigs, retractable

pins for sphere loading etc.?

)

)

Overbore diameter and length – wall thickness is an

important measurement as a heavy wall thickness will

reduce the overbore internal diameter making pig loading

difficult. Is its length sufficient to contain the pig?

)

)

Nominal pipe length – the requirements differ for launch

and receive traps.

)

)

Tees – do they have pig bars fitted?

)

)

Height and angle of the pig trap – offshore the pig traps

are often vertical to save space.

)

)

Is sufficient space available in front and to the side of the

pig trap for access?

)

)

Is sufficient space available above the pig trap? Are there

any overhead obstructions like electrical cables (often

found if the pig trap is in a busy city location) or steelwork

on offshore facilities?

)

)

Pipeline pressure – low pressure gas pipelines can cause

severe velocity excursions during pigging, which may

impact data integrity.

)

)

Flowrate – is there sufficient flow to propel the pig? Is the

velocity so high a bypass system is required on the pigs?

Once all of this information has been gathered, it is good

practice to photograph the site area, walk around the pig trap

and take photographs from all sides, highlighting any pipework

or obstacles located in its vicinity.

Logistics

Once you are confident with the information collected you

will need to envisage how the inline inspection (ILI) tool and

relevant associated support equipment will arrive in front of

the pig trap. Consider, for example, a 48 in. inspection pig that

could weigh upwards of 6 t, something which will require a

substantial crane along with transport to locate it in a suitable

position for loading in to the pipeline. This assumes your pig

trap is accessible by road.

For an offshore location you may need a dedicated

support vessel. How will you lift the pig from the boat to the

platform – will the same crane be utilised for lifting it to the

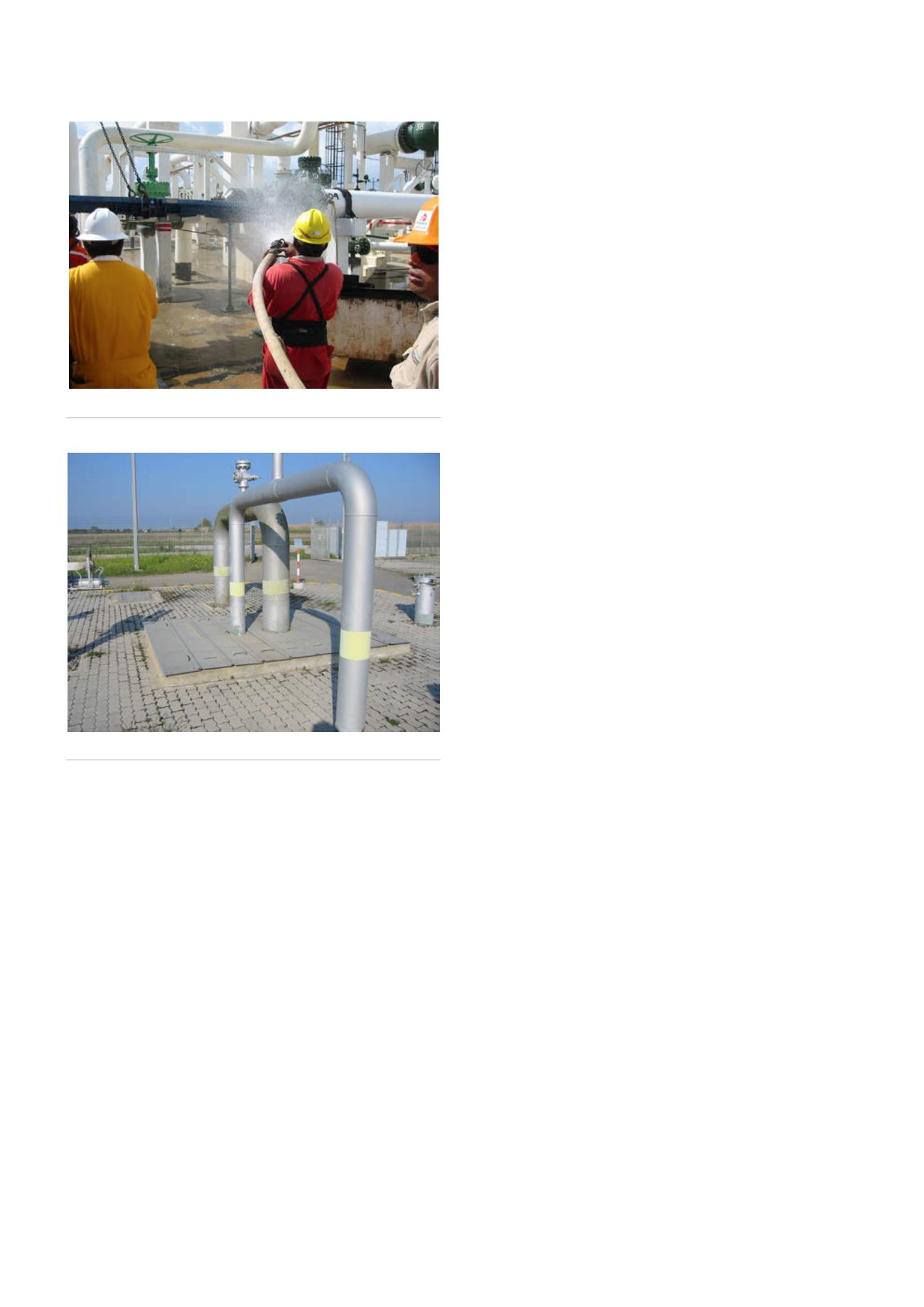

Figure 2.

Back-to-back tees.

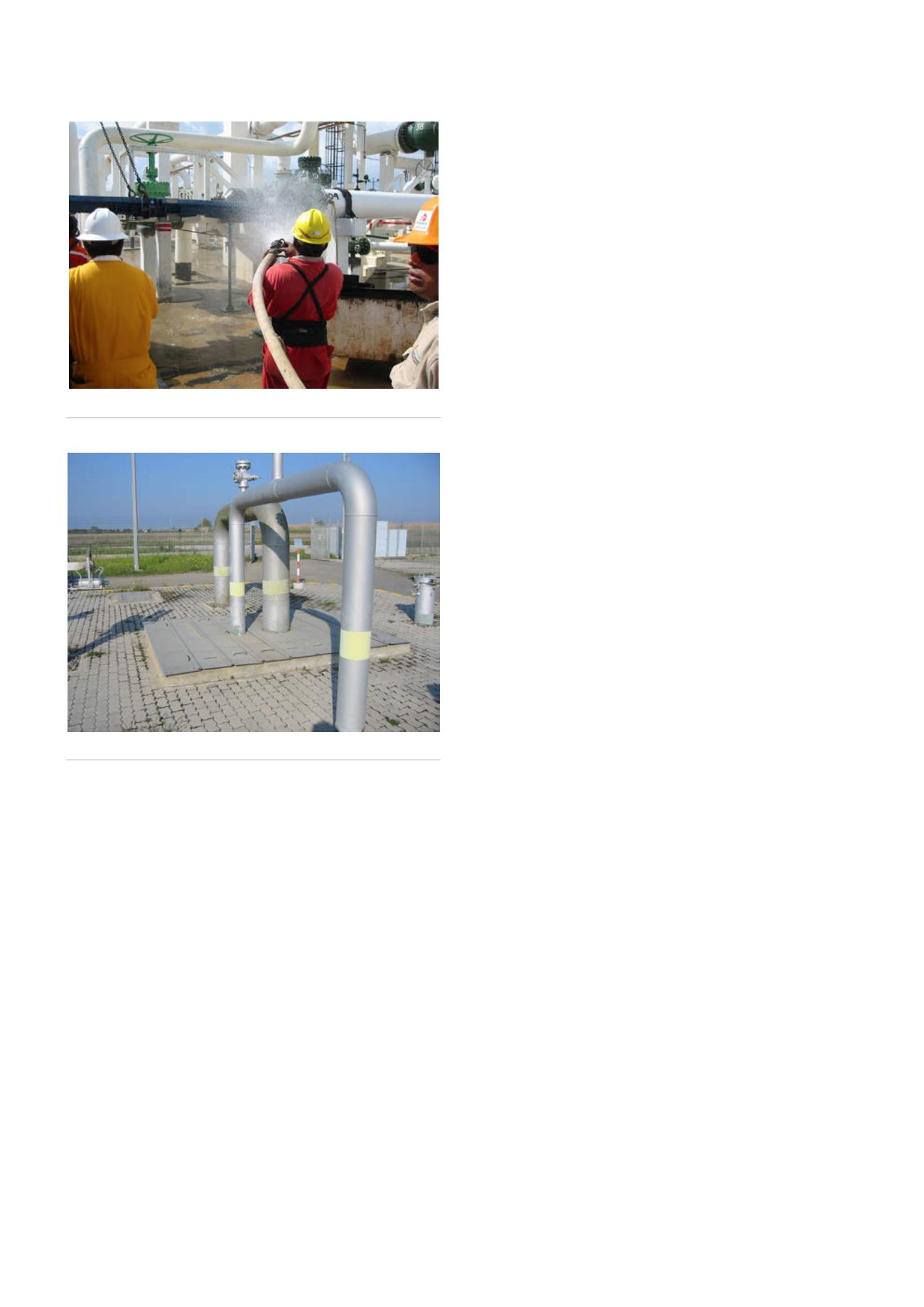

Figure 1.

Hazardous products.

92

World Pipelines

/

FEBRUARY 2016