bring as much information as possible on the transit of the

next device. OptaSense eliminates both the cost of the all

of the manpower associated, and in most cases, the effort

associated with the next pigging run – the information is

already known.

The worst case, however, is when a pig is accepted

as being stuck – but the information will only vaguely be

known – an inaccurate estimate may be provided from a mass

balance system for example. But this is often only accurate

to a few kilometres. The next and fairly serious step may be

to drill a hole in the pipe to try and establish whether you

are upstream or downstream of the pig – narrowing in on

the device. Finally, when it is close, a large section of land

might be excavated until it is fully zoned in on and cut out.

OptaSense can reduce these costs to a bare minimum by

identifying the location of the device to within a few tens

of metres from the trace and then on the ground by simply

walking up and down the controller can direct the field team

to the precise last location of the pig – accurate to ~10 m.

Finally, in the case of waxy deposits or condensate lines,

if there is a concern that a build-up of deposits or particular

geometry issues may lead to a potential stuck device, the

speed profile of each run can be compared back to the

flow profile or pressure profile and locations where marked

speed deviations are evident, and can be easily identified

and marked for careful live observations during subsequent

transits. Potentially avoiding more damaging incidents – or

feeding into a control loop to ensure that speed is kept above

a minimum. Note that without live feedback, speed profiling is

only ever achieved during the infrequent statutory inspections

– every run between that is carried out

largely blind.

Conclusion

Pigging is one of few activities that

are carried out on pipelines that are

of significant importance, have major

cost implications and yet are so poorly

monitored: other than during instrumented

inline inspection – where the data can only

be reviewed after the event. There is a need

to provide feedback to pigging operations –

to keep the man out of the field, to provide

dynamic control and to provide knowledge

over the status of the pipeline. Rather than

aggregating that information to a summary

of what was extracted from two remote

points or how long the transit took, there is

a need for a better solution.

Live pigging observation from DAS can

provide this mechanism by placing ears

every 10 m along the pipeline – giving the

controller immediate feedback on the status

of their operations. This has the

potential to deliver significant cost

savings and safety enhancements

by allowing staff to monitor pigging

activities safely from the control

centre and can vastly decrease the

costs of dealing with devices stuck

in pipes.

The benefits of using DAS for

pigging operations have been rapidly

realised by those customers who

have invested in DAS for pipeline

leak detection or pipeline leak

prevention operations: there is

significant benefit in either using

DAS as a service during pigging or

inline inspection operations – or as

part of a permanent fit. All that is

required is a fibre optic cable in the

vicinity of the pipeline.

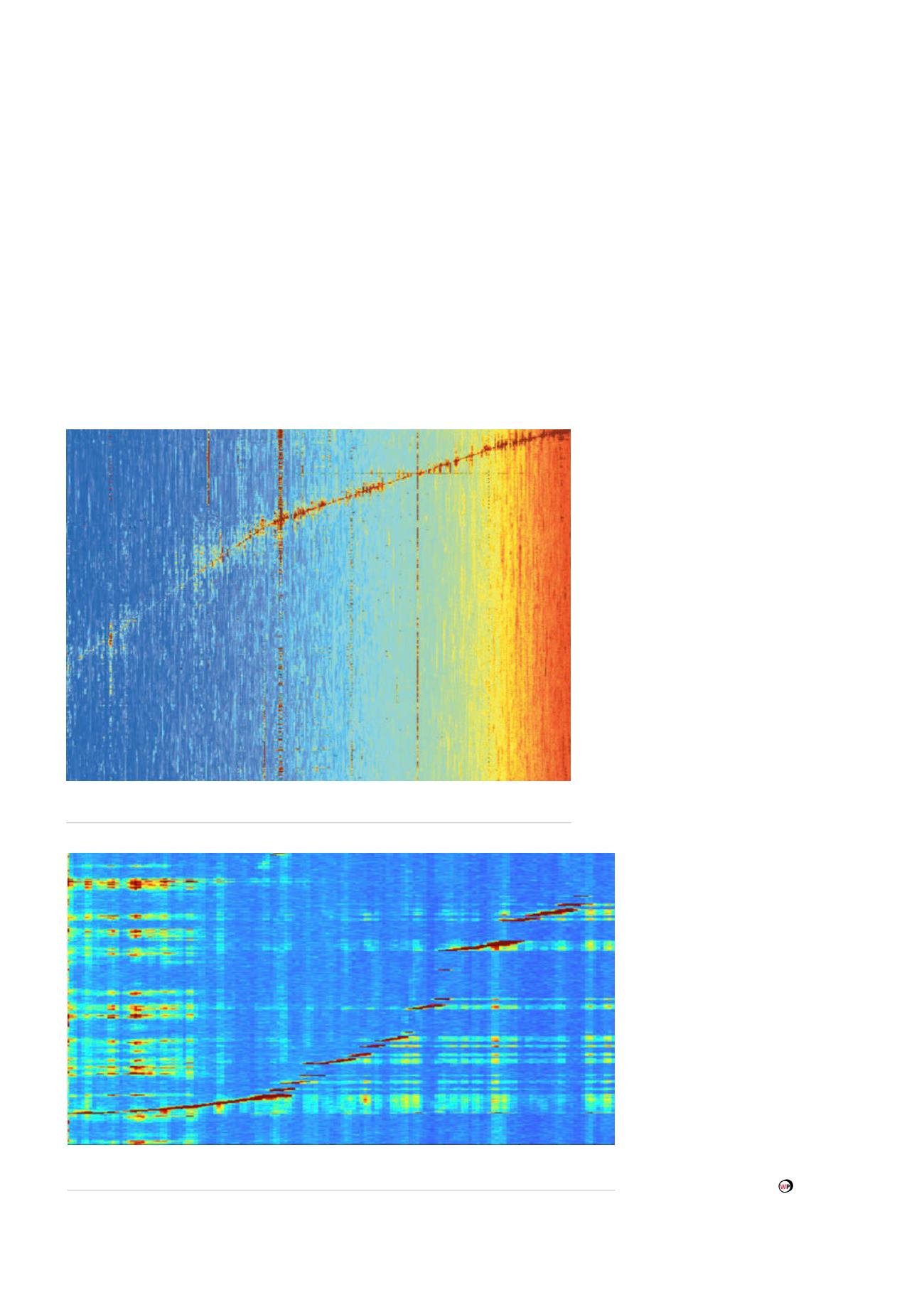

Figure 6.

An example of a cleaning pig in a gas pipeline experience momentary stops in

transit due to a combination of pressure and fit.

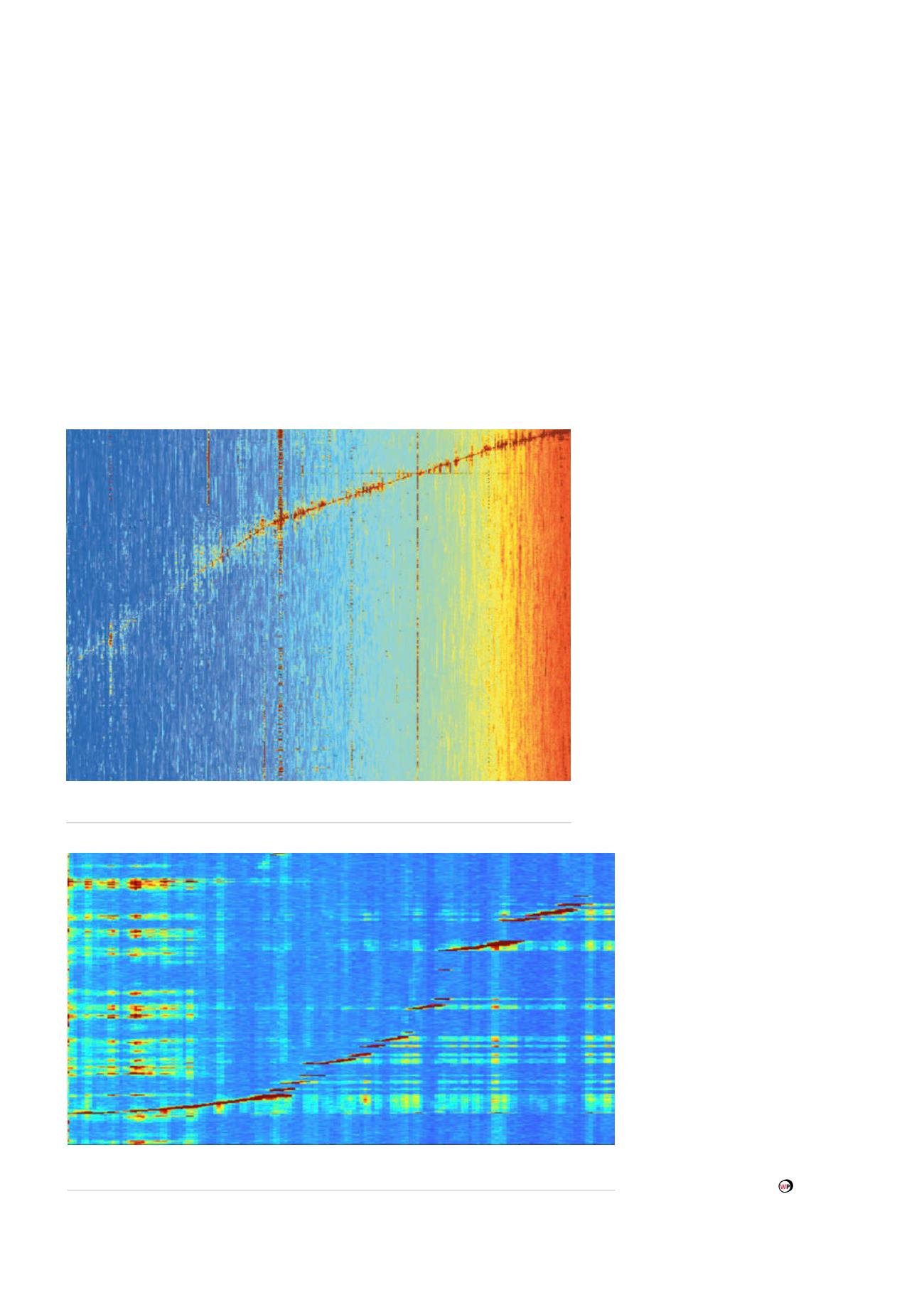

Figure 5.

Example from a North African installation where a change in flow

conditions in a first charge on a gas pipeline results in an abrupt change in speed.

90

World Pipelines

/

FEBRUARY 2016