contractor J&P-AVAX regularly having to encounter steep slopes

of sometimes 30 - 35˚ inclination.

Working safely in this tough environment was the most

important consideration for this contractor and why, on this

project, the company elected to rely only on Volvo CE’s rotating

pipelayer technology for all pipe handling duties. The company’s

fleet comprised 16 units – 10 PL3005D (51 t tipping capacity),

five PL4608 (80 t tipping capacity) and one PL4809D (90 t

tipping capacity, and up to 102 t with the optional, additional

counterweight). The additional counterweight is ideal when

working with a boom extension for tie-in operations or pipe

unloading and stacking. The smaller PL3005D features an extra

heavy, standard counterweight for added stability.

John Joannou, responsible for machine procurement at J&P-

AVAX, said at the time: “I was impressed by the machines’ excellent

stability. The 360˚ swing capability, cab comfort and the load

management system (LMS) is much appreciated on this hilly project.”

Unrivalled safety

Safety is at the forefront of Volvo’s rotating pipelayer design.

Lowering-in pipe on steep slopes, or even travel on steep

slopes, is not without its hazards. Gravity takes over, allowing

the pipe to swing downhill and increase weight to the rear,

which can be potentially dangerous. With Volvo’s unique,

360˚ upper structure swing capability, the boom can simply be

positioned uphill, thereby allowing the load to be kept ahead of

the machine, ensuring better stability and operational safety in

these demanding conditions. Boom pads fitted to the underside

of the boom will protect the pipes from damage, although it is

not uncommon for a contractor to apply additional padding to

help hold the pipe more steady and prevent swinging, thereby

minimising unnecessary concern for the operator who can then

focus on the task in hand.

The tendency for pipe to swing downhill on a slope naturally

puts extra strain onto machine components. To overcome this

problem Volvo pipelayers feature a heavy duty, hydro-mechanical

slew lock. This lock can be engaged at every 10˚ interval around

the slew ring, enabling the operator to lock the upper structure

at the most appropriate angle to combat pipe backswing while

at the same time resisting additional strain and wear on the

machine’s components. The steeper the slope, the more the

boom can be positioned towards the front of the machine. When

working on tie-ins, this slew lock feature enables the pipe to be

held steady during the start of the welding process.

Carlos Aiello, a pipelayer operator with French contractor

SPAC, appreciated the slew lock for other reasons, commenting:

“It is a very delicate operation doing tie-ins and this machine

is extremely stable and precise. I also like the machine’s upper

structure swing lock feature for pulling pipes under crossings.”

Improving further still its slope performance, the latest model

PL4809D brings a 70% improvement in tractive force enabling it

to climb a 30˚ slope with ease with a heavy load in the hook, in

addition to its ability to move with ease over rough terrain.

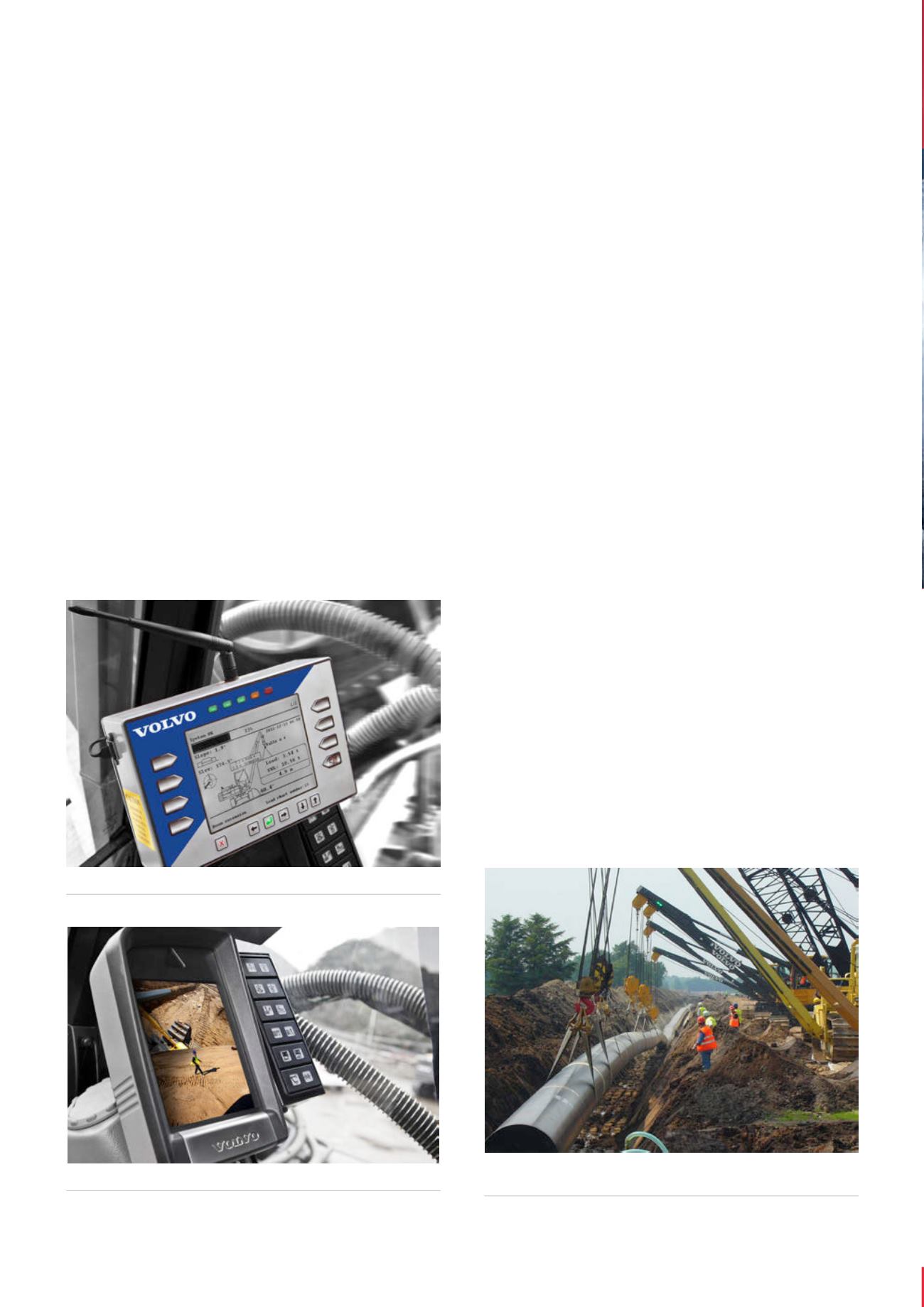

Precise load management

A further safety enhancing feature is the machine’s unique,

onboard LMS, which alerts the operator of the need to engage

the machine’s heavy-duty, hydro-mechanical slew lock on slopes

above 10˚ and is calibrated to work on all slopes up to 30˚.

Using sensors mounted on the boom and on the machine’s

upper structure, the LMS permanently monitors the slope

inclinations – fore/aft and lateral – boom angle, orientation and

load. Information is fed continuously to the operator, via both

Figure 2.

State-of-the-art, onboard LMS.

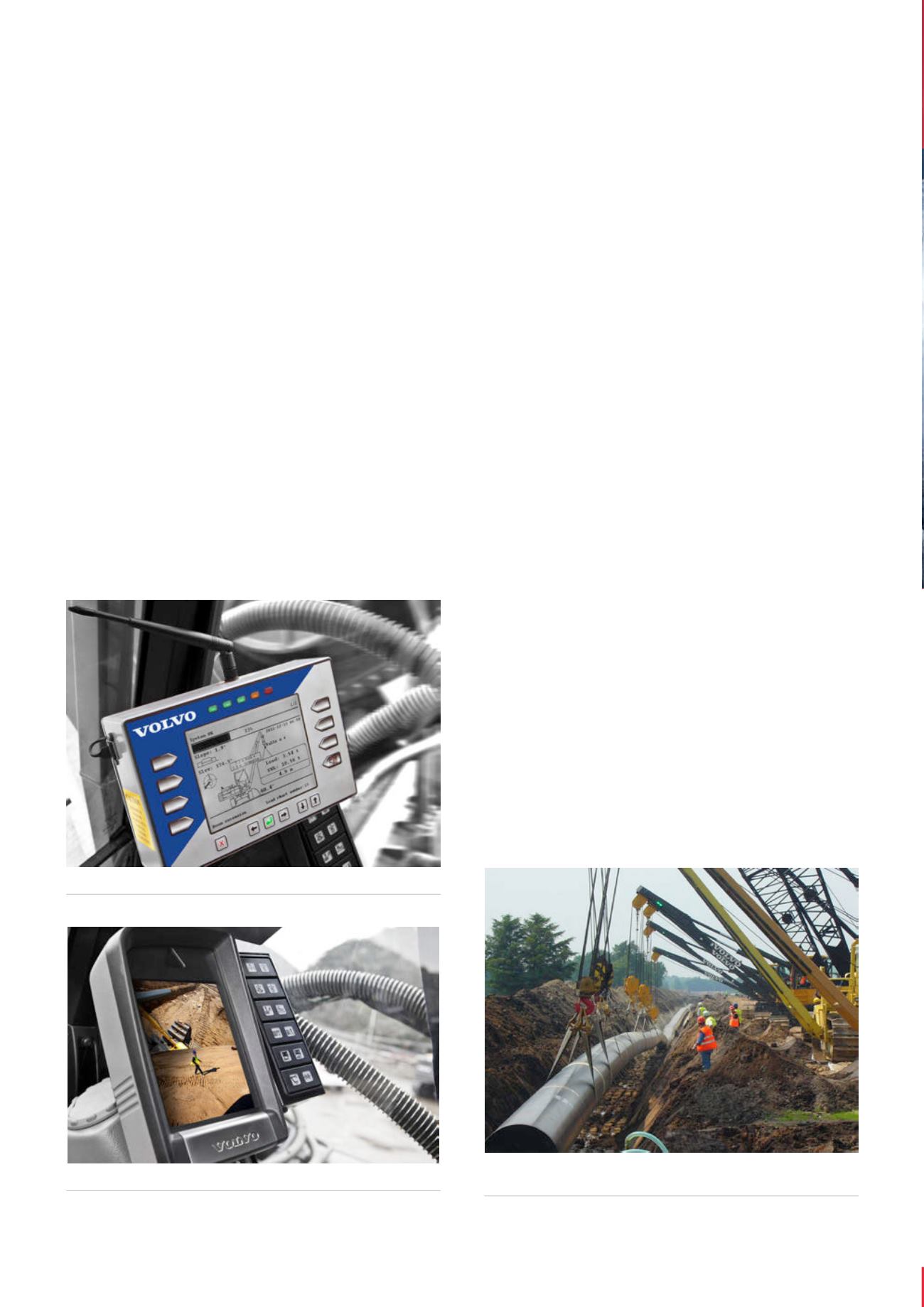

Figure 3.

Cameras enhance site safety.

Figure 4.

Lowering-in alongside both sidebooms and crawler

cranes on the Bunde-Etzel 48 in. pipeline in northern Germany.

100

World Pipelines

/

FEBRUARY 2016