Documentation and execution

Once the line is confirmed piggable the execution phase

requires a comprehensive range of documents, which could

include:

)

)

Health, Safety and Environment (HSE) policies.

)

)

HAZID review documents.

)

)

Material safety data sheets.

)

)

Project, inspection vendor and waste disposal method

statements.

)

)

Site pigging procedures.

)

)

Lifting plans.

)

)

Pig run contingency planning.

)

)

Inspection vendor equipment lists.

)

)

Reference drawings.

)

)

Project plans and relevant project documents.

)

)

Contact lists.

)

)

Post run decontamination procedure (NORMS, mercury,

benzene etc. can all contaminate pipeline pigs).

Prior to mobilisation, a factory acceptance test (FAT)

should be performed with the ILI vendor to identify any

issues prior to incurring costly mobilisation charges. On

a recent FAT visit I captured the inspection tool vendor

preparing to mobilise a lower specification tool than that

specified, something an inexperienced operator might have

missed.

So now you have got your people in-country, all the

required training is complete, the inspection tool is at the pig

trap and the technician informs you there is an issue with the

tool and it cannot therefore be run.

OK, this may be an exceptional circumstance, but it

does happen. Reasons could include flat batteries, faulty

electronics, damage which occurred during transportation

and a host of other things. Sometimes these issues can be

resolved onsite, but what if the length of time to fix the

problem means you have missed the batch of product that

you were going to use to propel the tool?

Now assuming the pig has been run, then everyone

will be eager to know the outcome of the inspection with

the onsite technician under pressure to ‘tell me where

there’s a defect?’ from the often expectant client. Now,

the most you can expect from the field technicians onsite

is confirmation that the tool has or has not functioned

correctly, and whether it has or has not collected a full

data set.

Issues with incomplete data can be attributed to:

)

)

Debris in the pipeline – who was responsible for cleaning

the pipeline?

)

)

Damage to the inspection tool – a partially closed valve,

velocity excursions, wear and tear, etc. could all be

contributors.

)

)

Product issues, flow, velocity, pressure, temperature etc.

)

)

Onboard electronics issues.

)

)

Sensor issues causing data loss.

This list goes on. As inspection tools are in high demand,

some negotiation will often take place with the inspection

tool vendor, trying to persuade you to accept the degraded

inspection data. The implications of any decision to accept

data of a degraded quality need to be fully understood

along with the impact this will have on any future integrity

assessments planned.

With a large percentage of the world’s pipelines still

considered unpiggable for current inspection technologies,

a well-executed piggability study along with a well planned

and executed inspection programme will help fill in the

blanks for you and may just keep you one step ahead of the

regulator.

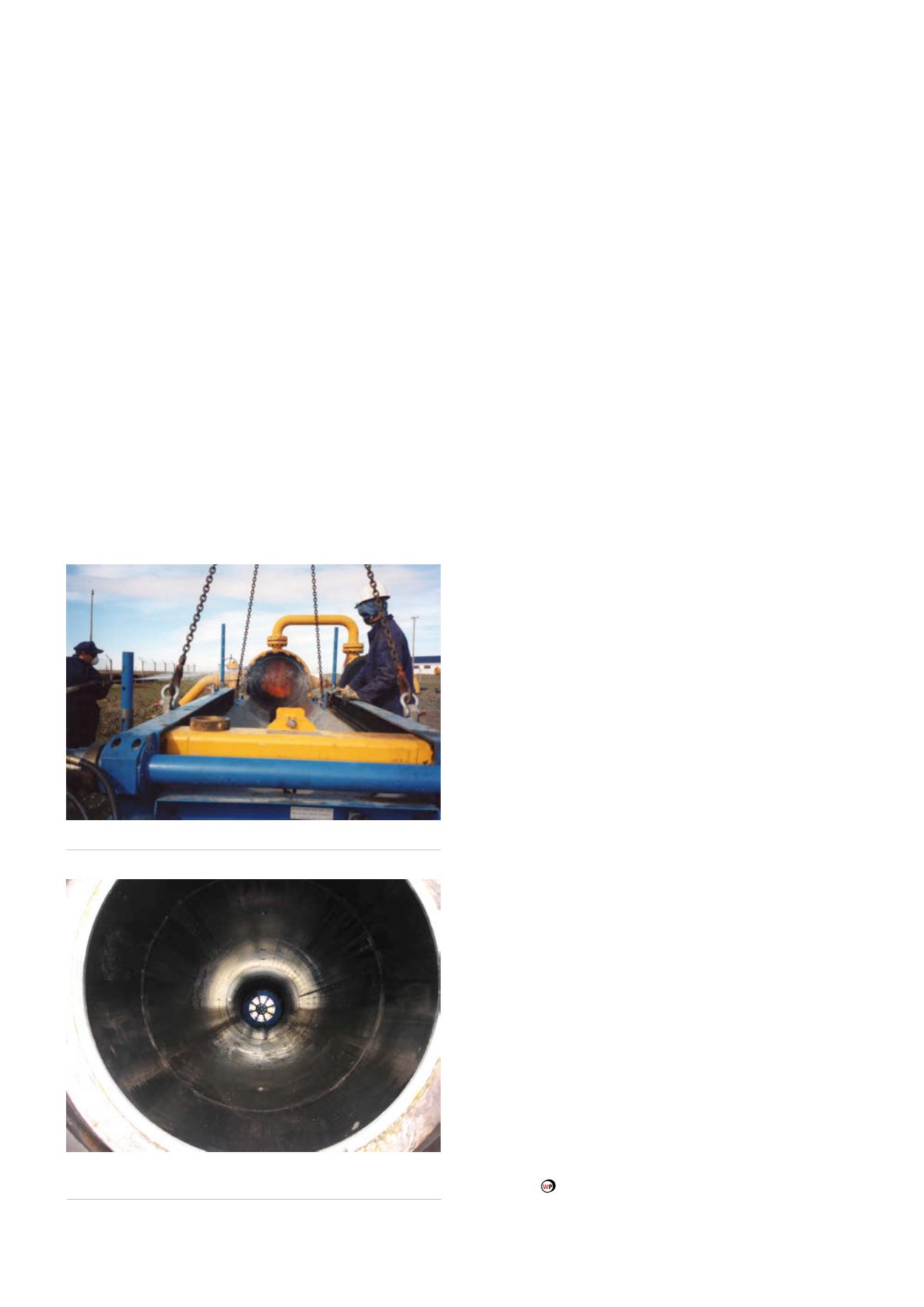

Figure 6.

Pyrophoric dust on fire inside the pig trap.

Figure 5.

The end goal, a clean pipeline and a successful

inspection.

94

World Pipelines

/

FEBRUARY 2016