Any conventional tracking is either done by failure-prone

mechanical reed switches or direct listening in the field –

creating an additional maintenance burden and cost – and in

the case of working in a hazardous security environment, a

simple inspection action may become significantly burdened

by personnel protection costs and logistics. Recent advances

in external pipeline sensing with fibre optics (distributed

acoustic sensing: DAS) have revolutionised pipeline security

and theft prevention activities, and are poised to bring

similar benefits to leak detection activities. They can also

bring significant cost savings to conventional maintenance

operations.

Such systems act as highly sensitive, highly distributed and

highly accurate microphonic sensors virtualised across the

whole pipeline length, and can bring massive operational gains

to the conduct of pipeline scraping or inspection activities:

bringing a real time perspective on operations and absolute

position measurement at any time.

The value of this is not limited to speed tracking of pigs or

inspection devices, but includes a stuck pig location (to within

±

10 m) and immediate awareness of re-movement, distributed

flow profiling, slack line monitoring, highly accurate time to

trap alerts, gas pressure profiling, slug monitoring, multiple

pigs headway monitoring, and speed trace monitoring (in

static flow conditions). This article explores the methods of

monitoring internal pipeline operations from an external fibre

optic sensor, and illustrates from real world examples the

benefits that can accrue.

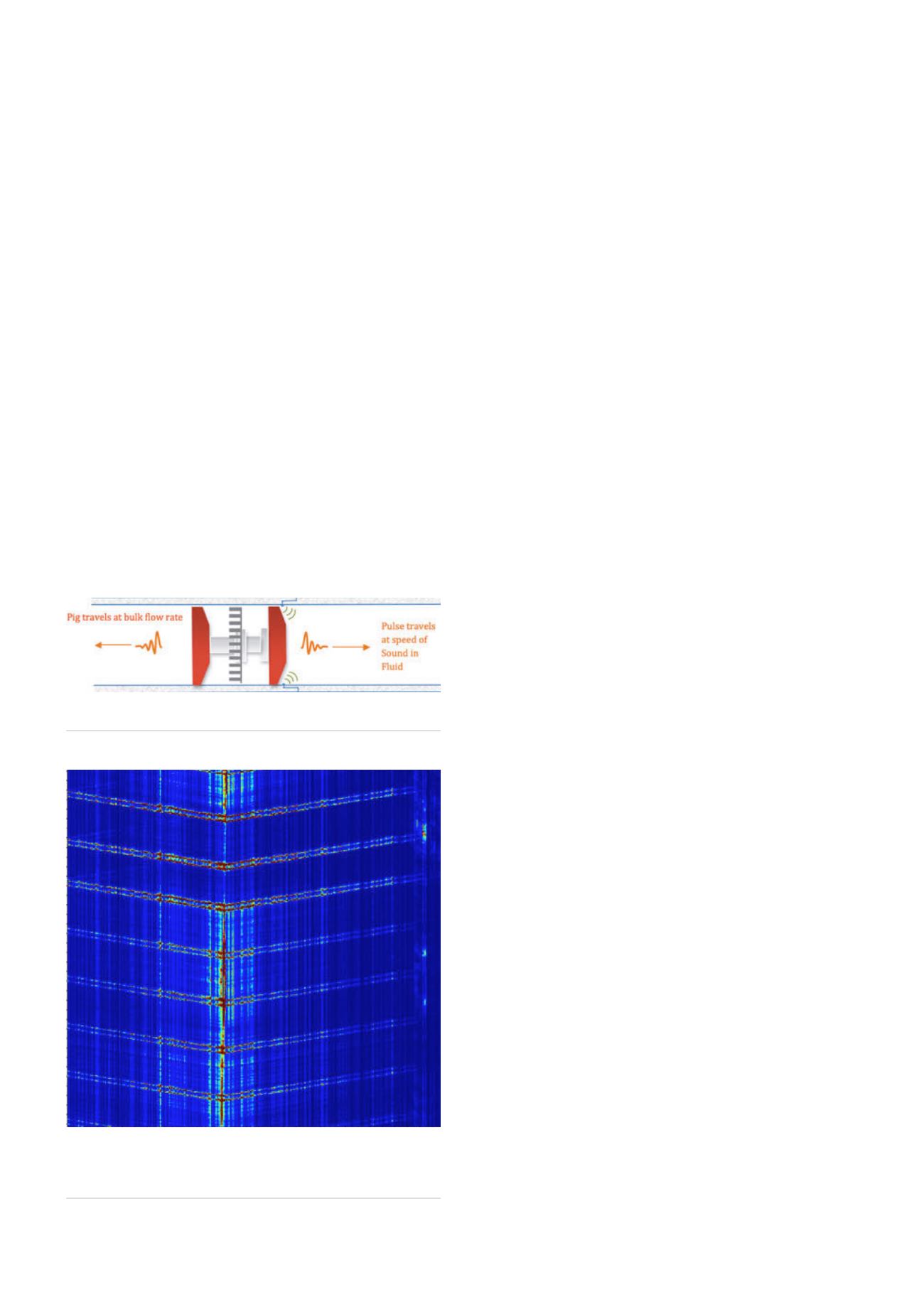

Principles of operation

The passage of a cleaning pig or inspection device produces

two distinct acoustic signals that are readily identified:

)

)

A low frequency rumble produced by the continuous

contact of the pig with the pipe.

)

)

A series of regular broadband pressure waves (transient

impulses) caused by the impact of the pig seals with the

butt welds.

This latter trace gives the passage of a pig a distinct

heartbeat, which is at the heart of DAS pig tracking

capabilities. The pressure wave extends far down the pipe in

either direction as a shock wave travelling at the speed of

sound in the product, typically ~1200 m/sec. in oil and

400 - 900 m/sec. in gas: dependent on pressure and

temperature.

A process analogous to a water hammer effect produces

the shock wave, whereby the laminar flow of the product

is suddenly brought to a momentary stop by the pig skirt

interfering with the weld on the two pipeline segments. This is

sufficient to produce a significant low frequency shock wave

that can extend many kilometres in both directions in the

pipeline fluid (liquid or high pressure gas).

These signals are easily detected by a close fibre optic

cable (to a few metres distant), which is connected to a

DAS interrogator. The DAS system converts the standard

telecoms fibre into a series of continuous, distributed

virtual microphones – typically 10 m in length – many

thousand across the complete length of pipeline. Each

virtual microphone corresponds to a specific 10 m section of

pipeline – whose position is easily calibrated. By continually

observing the signals at a sufficiently high frequency (typically

2500 Hz) the microphone output from each microphone can

be recorded over time. By performing these calculations in

parallel over every channel in real time, the acoustic profile

of the pipeline valid for that instant in time can be derived.

By observing this over an extended period, the behaviour of

static and dynamic artefacts can be continually monitored.

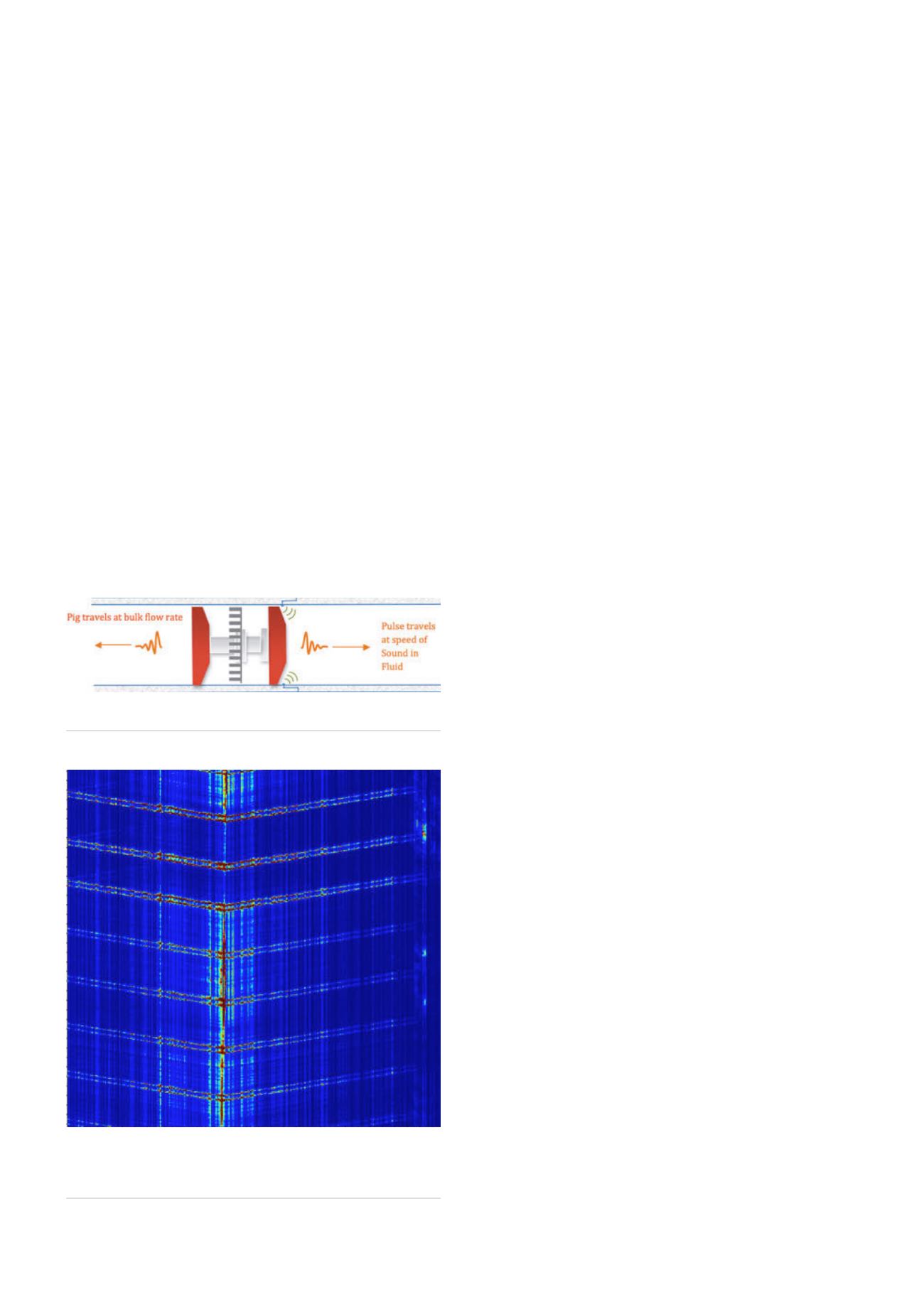

Automatically detecting, classifying, and locating the trace

via online detectors easily track devices, such as pigs tracked

along the pipeline with a positional resolution close to the

channel size – down to 10 m. This means that the passage

of the pig can be observed and listened to from a central

remote location. In Figure 1, there are a number of features

characteristic of the passage of a cleaning pig:

)

)

Double shock wave from the front and back skirts of the

scraper.

)

)

Separation of shock waves by a time corresponding to the

~11 m pipeline segment length.

)

)

Speed of sound in oil propagation (~1200 m/sec.

-1

) of

shock wave down the pipe.

Figure 1.

Schematic of a cleaning pig passing a butt weld and

the generation of the pressure pulse.

Figure 2.

Pipeline shock waves and interference noise from

a passing cleaning pig – with distance horizontal and time

vertical, the pressure pulses can be observed travelling in both

directions.

86

World Pipelines

/

FEBRUARY 2016