)

Facilitates regulatory compliance.

)

Decreases environmental incidents.

)

Improves safety.

)

Reduces need for visits to the pump station.

)

Provides troubleshooting information.

)

Increases uptime.

)

Optimises operation.

Maintenance costs are cut because it is no longer necessary to

overhaul or perform maintenance on pumps on a periodic basis, or

in response to a problem. Instead, pumps can be maintained only

as needed, and with proactive rather than reactive scheduling.

API Standard 682 requires monitoring of pump seal systems,

and other regulations also require varying types and levels of

monitoring, all of which can be done more efficiently with

instrumentation and control systems as opposed to manual

methods.

Environmental incidents can be decreased because pumps

and related systems can be continuously monitored for leaks,

over pressure conditions and high temperatures. Some of these

conditions, such as leaks, represent an immediate environmental

issue – while others can indicate conditions leading to possible

incidents.

Reducing incidents improves safety, and safety is also

improved because fewer site visits are required to check

conditions, which also cuts costs. Remote monitoring also

provides information to aid troubleshooting, so that when site

visits are required, technicians can arrive with the tools and parts

in hand to perform required repairs.

All of the information gathered by sensors can be sent to a

control system, where operators and engineers can use this data

to increase uptime and optimise operation, particularly with

respect to pump operation and flow measurement.

Flow measurement

Flow sensors close the loop on pump systems, as information

from these devices is used to regulate the speed at which pumps

run, and/or to modulate flow control valves. These sensors are

installed at various points in the pipeline system starting at pump

output, and continuing downstream to ensure proper flow is

maintained throughout the pipeline. The most common type of

flow sensors in pipeline systems are ultrasonic and coriolis.

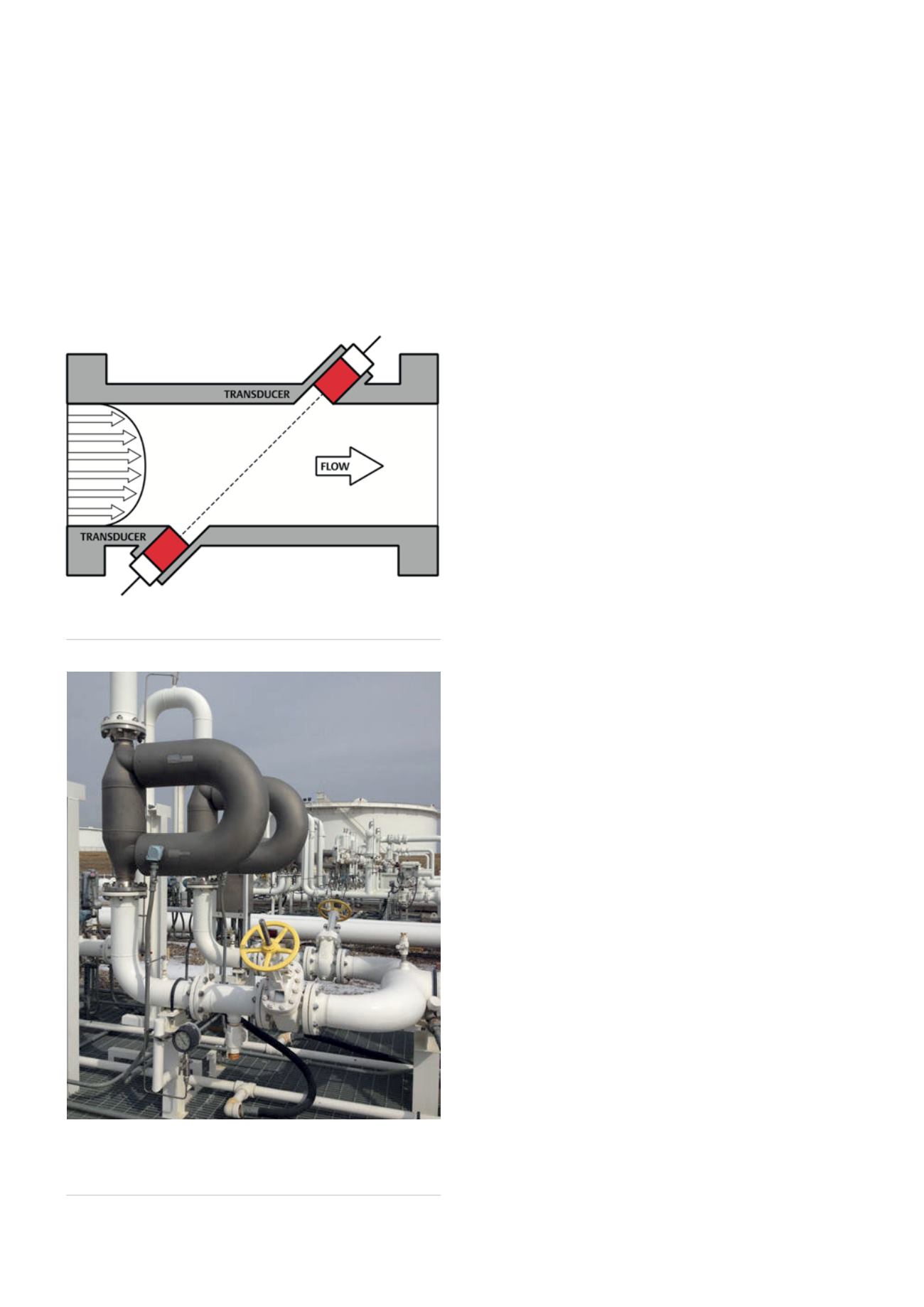

Ultrasonic flowmeters use the transit times of high frequency

sound pulses between a pair of transducers to determine fluid

velocity. A transducer pair is positioned within a meter tube body

to enable the pulses to be transmitted diagonal to the direction of

the fluid flow (Figure 3). Each transducer alternates as a transmitter

and a receiver, resulting in pulses being transmitted against and

with the flowing fluid.

A pulse travelling with the flow traverses the pipe faster than

the alternate pulse travelling against the flow, with the resulting

time difference proportional to the velocity of the fluid. Relating

this velocity to the known diameter of the meter tube results in a

continuous inferred volume measurement.

Multi-path meters for pipeline custody transfer and pump

efficiency tend to be more accurate since they collect velocity

information in several points of the flow profile. Ultrasonic meters

are typically considered because they are non-obstructive, have

no moving parts, accommodate high volume applications, and are

self-diagnosing.

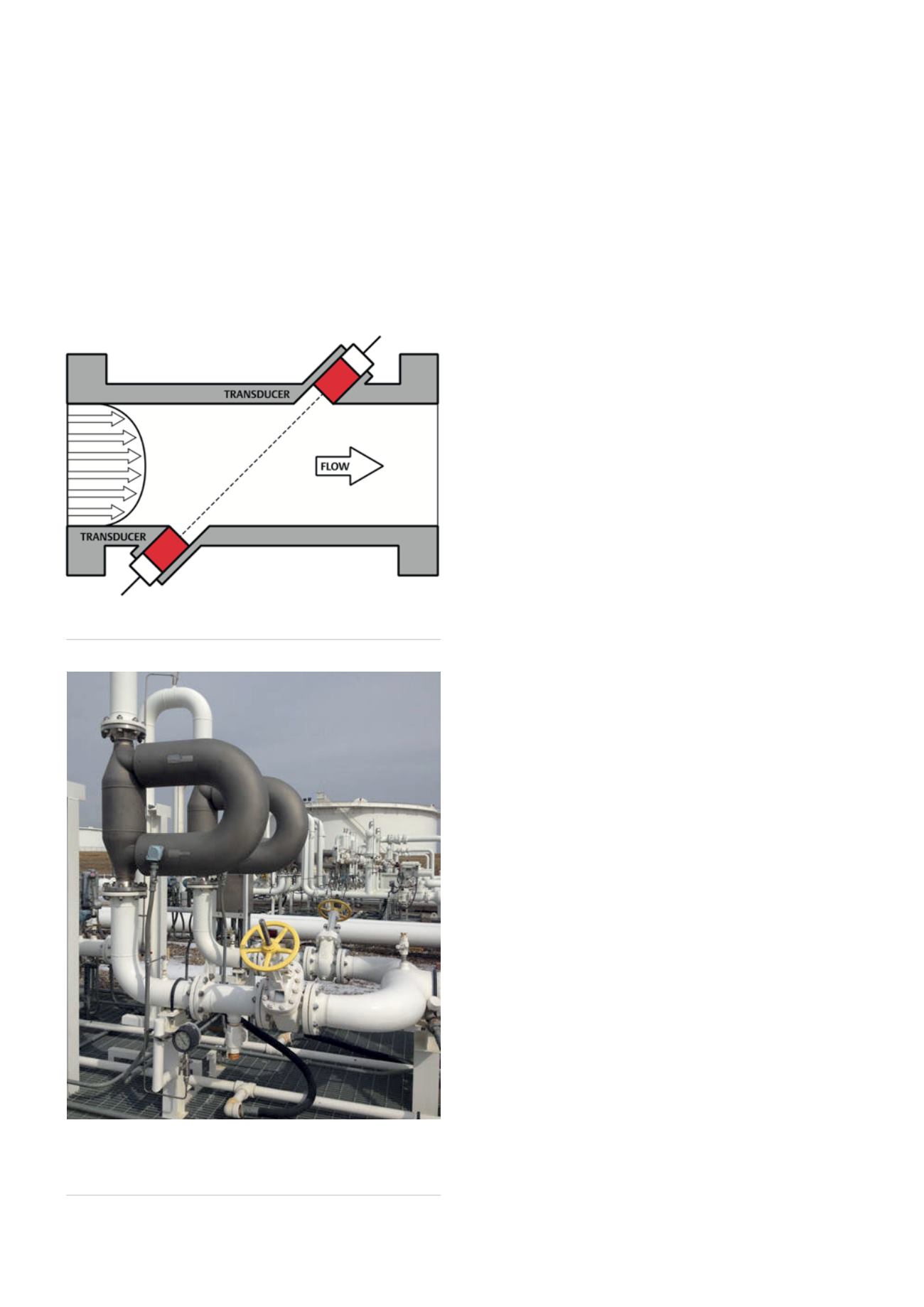

Coriolis flowmeters are unique because they can measure

either mass or volume flow, or both simultaneously (Figure 4).

Coriolis meters are well known for accurate and long-term

measurement stability under varying process conditions. They

are able to measure different fluids including both liquids and

gases without the need for recalibration. Coriolis meters are not

Figure 3.

Ultrasonic instruments transmit and receive pulses

diagonally across pipes to measure fluid flow.

Figure 4.

The gray U-tube design of each of these two micro

motion coriolis meters are clearly visible at this pipeline

receiving station for a major storage terminal in Cushing,

Oklahoma.

78

World Pipelines

/

FEBRUARY 2016