reporting on meter proving, prover certification, transmitter

verification, and test equipment certification in accordance with

American Petroleum Institute (API) guidelines.

Importance of accurate measurements

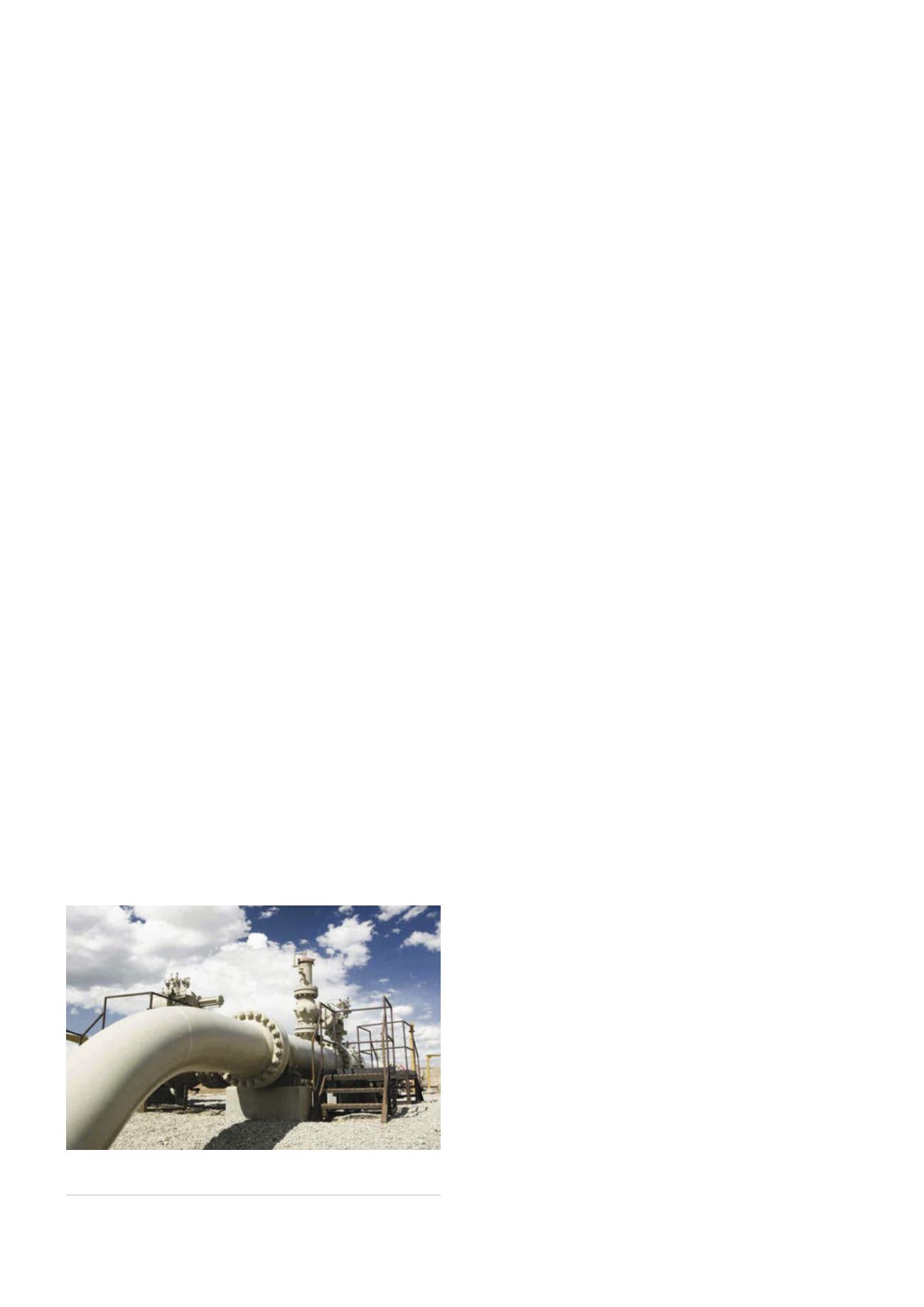

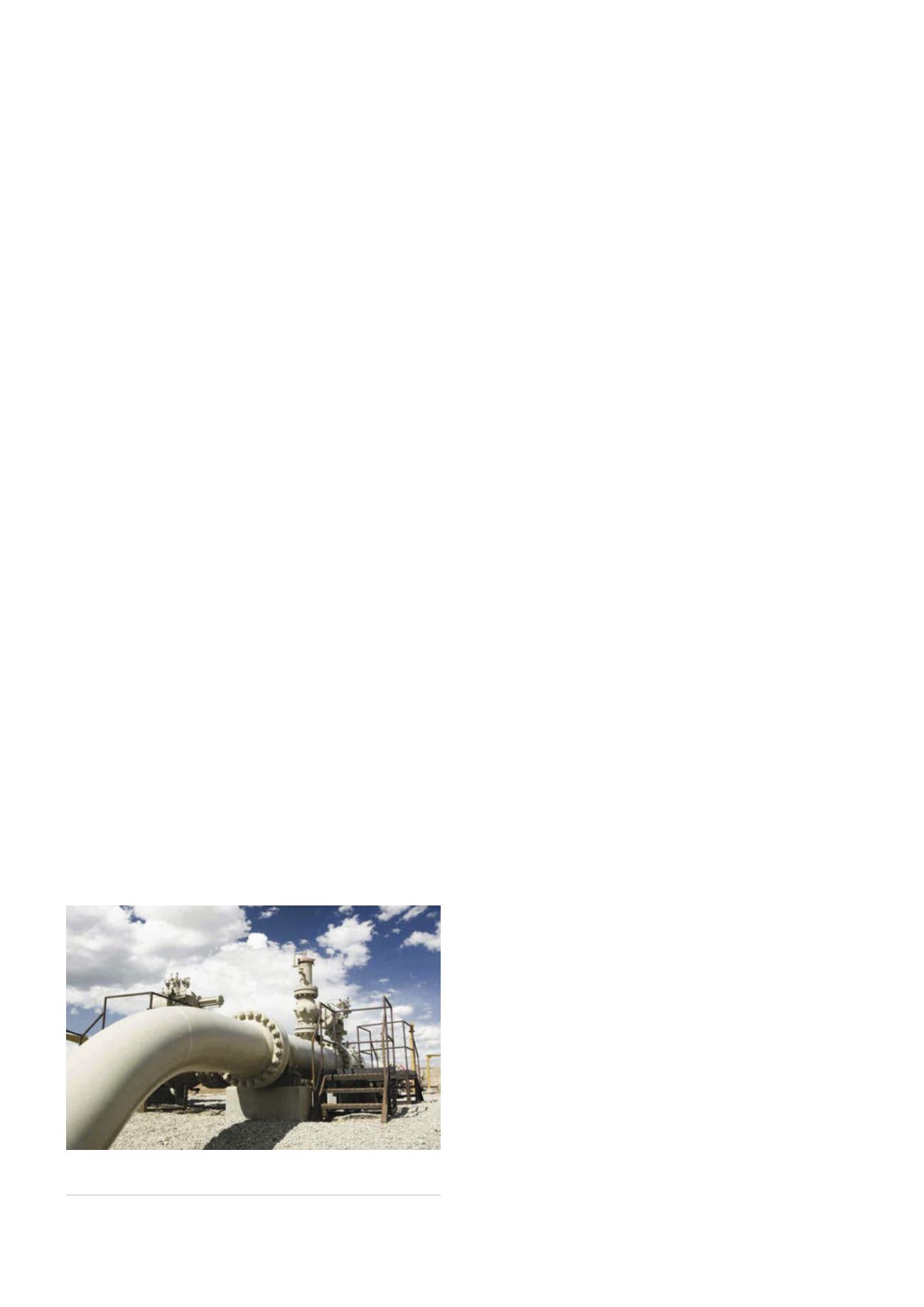

When it comes to moving oil and gas though pipelines, the

accuracy of flow measurement devices is a top priority –

particularly in the custody transfer (sometimes called ‘fiscal

metering’) process. Ensuring and maintaining precise measurements

is essential for efficient and profitable operations, as well as fair

transactions.

Custody transfer applications involving oil and gas are

influenced by:

)

)

Industry regulations.

)

)

National metrology standards.

)

)

Contractual agreements between custody transfer parties.

)

)

Government regulation and taxation.

Pipeline metering systems must provide a single, accurate

number representing a fiscal measurement. It is important that

this single version of the ‘truth’ is accurately captured, recorded,

and made visible throughout the organisation and among all

the vendors. Due to the high level of precision required in these

applications, metering technologies are subject to approval by

industry organisations, such as the API.

For custody transfer of oil and liquid products, physical

proof testing to assure meter accuracy is essential. Measurement

performance is monitored through the regular inline proving

of meters under actual field conditions, and meters must be

adjusted to accommodate changing process parameters, such as

temperature, flowrate, pressure, density and viscosity. A variety of

proving systems can be used for this task, including ball provers,

small volume provers, bi-directional provers, master meters, tank/

weigh systems, and portable/stationary proving systems.

According to the API Manual of Petroleum Measurement

Standards (MPMS), the purpose of meter proving is to determine

the meter factor. The meter factor is an essential element in

calculating the net standard volume of a receipt or delivery of

petroleum liquids in the supply chain, and is obtained by dividing

the actual volume of liquid passed through the meter during

proving by the volume registered by the proving device.

Meter proving is only part of the compliance puzzle. Prover

certification, transmitter verification and calibration, and test

equipment certification are also required. Through the verification

and auditing of metering systems at every stage of their use, it is

possible to guard against potential meter, instrument or system

problems, while guaranteeing trustworthy data reporting and

full traceability. This trust or lack thereof impacts the image

and reputation of the operating company and can influence the

financial bottom line.

Need to manage proving data

Petroleum producers manipulate vast quantities of meter proving,

transmitter and test equipment calibration, certification and

test data, and many companies rely on manual systems without

automation to support these critical regulatory and business

functions. In many cases, due to a company’s growth through

acquisition there are a variety of work processes and systems

involved. Typical challenges include:

)

)

Variety of data input mechanisms – meter factors and proving

records can be obtained electronically from a supervisory

control and data acquisition (SCADA) system or third party via

PDF document or a scanned, hand-written document.

)

)

Variety of record formats – due to the variety of data sources,

no standard record format or system of record is used.

Therefore, information is not readily accessible and useful

across the organisation.

)

)

Information stored in different locations – information is also

stored on individual employees PCs, on webservers and on file

servers, making it difficult to find and access the required data.

)

)

Formal scheduling and tracking process – most companies rely

on manual scheduling and tracking and do not have a formal

system to track when tests and calibrations were performed.

Proving test schedules are also dynamic based on the change

of products and percent change in meter factors, which also

complicates the scheduling process.

)

)

Detecting system anomalies and potential failures – without

a central repository, and historical records there is no

mechanism to monitor performance data. Without these, it is

impossible to detect degrading meters, transmitters and other

potential equipment problems.

For pipeline businesses of all sizes, manual data collection,

consolidation and reporting efforts are costly and time-

consuming. Manual audit report generation and data entry

frequently results in labour inefficiencies, as well as data quality

and transcription errors, missed scheduled provings, overlooked

prover anomalies, and lost or missed records. These problems

contribute to a lack of regulatory compliance, which can lead to

fines, lawsuits and shutdowns.

Pipeline operators require a robust solution to consolidate

information to respond to audits in a timely manner and meet

various contractual obligations. They also need tools to centralise

Figure 2.

Pipeline metering systems must provide a single,

accurate number representing a fiscal measurement.

70

World Pipelines

/

FEBRUARY 2016