This article will first examine the role of pump monitoring

sensors and systems in liquid hydrocarbon pipelines, and then

will touch upon measurement technologies, which work hand in

hand with control systems to manage liquid hydrocarbon flows in

pipelines.

Pump monitoring measurements

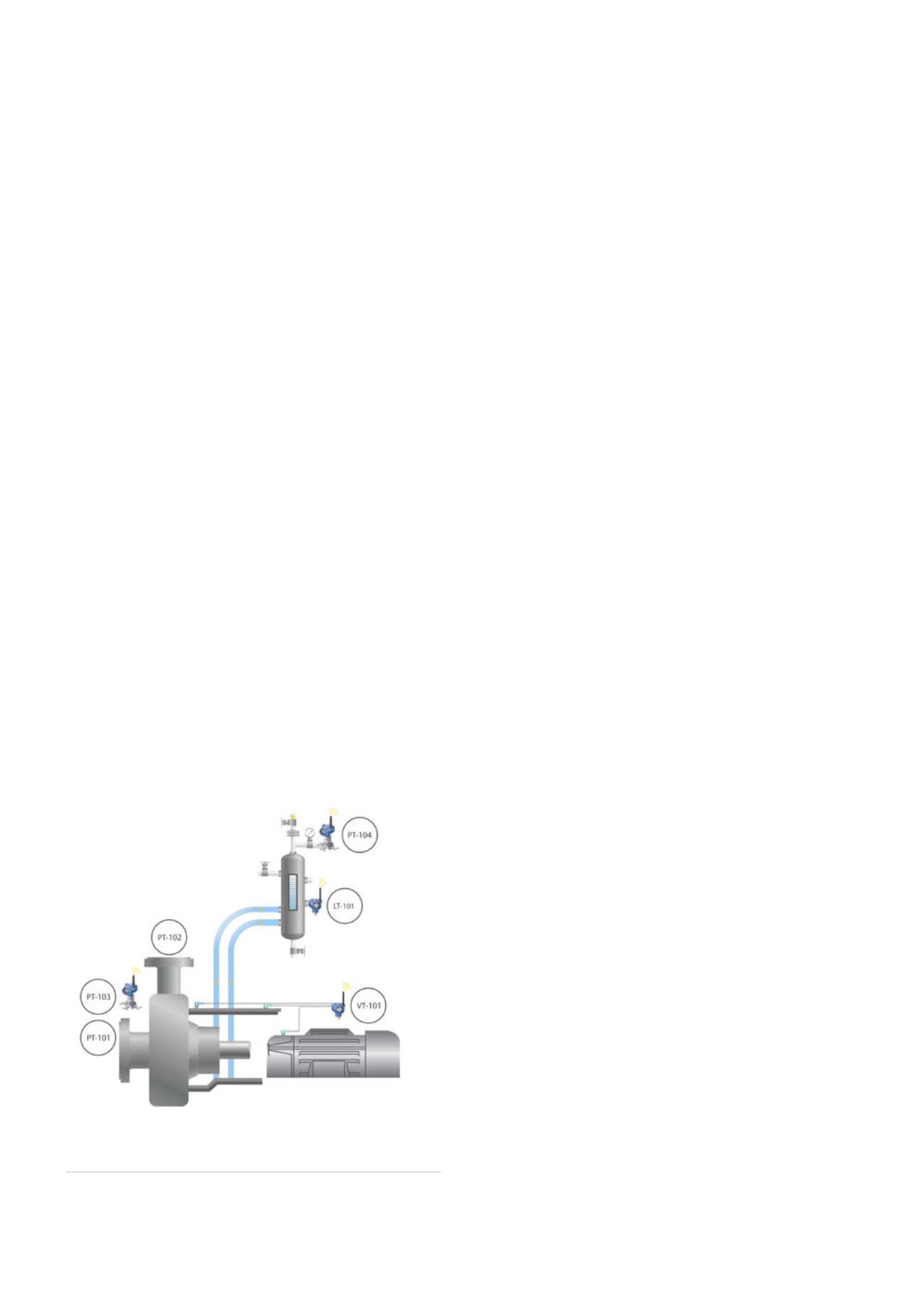

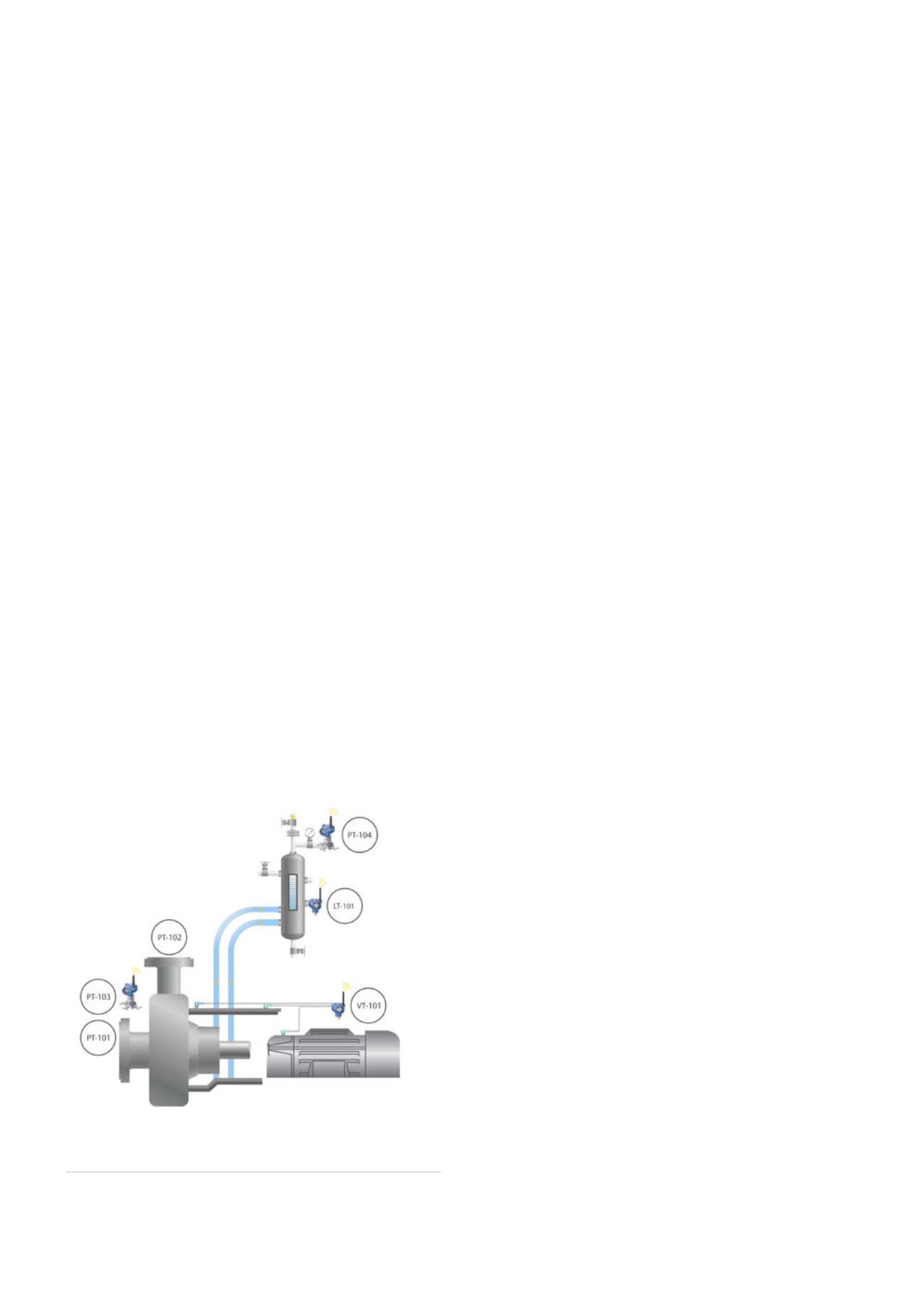

Pumps in pipeline systems are monitored with a wide variety of

sensor types, some of which are depicted in Figure 2 as wireless

sensors. Main monitoring points include:

)

)

Pressure at pump intake, PT-101 – ensures the pump has

appropriate pressure. If there is not enough intake pressure,

the pump can run dry, a particular hazard for centrifugal

pumps.

)

)

Level at pump intake – detects when the liquid level drops,

can be used to protect against dry running.

)

)

Pressure at pump discharge, PT-102 – used to infer the pump’s

level of output, and to ensure the pump is operating.

)

)

Flow at pump discharge – indicates proper pump operation,

and can be used to close the loop for pump control, as

explained more fully later in this article.

)

)

Differential pressure between pump intake and discharge,

PT-103 – detects cavitation.

)

)

Pump motor temperature – indicates when a pump motor is

running hot.

)

)

Pump bearing temperature – indicates when a bearing is

exceeding safe temperature.

)

)

Pump vibration, VT-101 – this measurement is a good

indication of pump health, particularly when tracked over

time and compared to a baseline. Increases in vibration

indicate conditions such as bearing wear or pump imbalance,

which can lead to failures.

)

)

Pump seal system reservoir level (LT-101) – indicates buffer

fluid level, recommended by API-682 instead of level switch.

)

)

Pump seal system vapour vent pressure (PT-104) – indicates

high pressure, normally a result of process liquids leaking into

the buffer system and flashing to the vapour phase in the

seal reservoir. Recommended by API-682 instead of pressure

switch.

As noted above, pump seal systems often require level and

pressure measurements. API Standard 682 Fourth Edition describes

changes in instrumentation used to monitor pump seal systems.

This new edition now indicates a preference for continuous

measurements using level and pressure transmitters versus the

prior practice of using simple on-off switches.

In some applications, a pump may have a filter or a strainer.

Installing a differential pressure sensor across the filter/

strainer will indicate when maintenance is required. Instead of

just manually checking pressure periodically, this signal can be

monitored to show when the filter/strainer should be flushed

or cleaned out, which will reduce excess strain on the pump by

removing the flow restriction.

On larger pumps, there may be a lube system. If this is a

pressurised lube system, a transmitter can be installed to ensure

proper lube pressure is maintained. This is important so that

process fluids in the pipeline do not contaminate the lube system.

Lube level is another important measurement, and can be made

with a level switch or transmitter.

Wireless sensors save

Wireless sensors are increasingly used in pump monitoring systems

because they are easier to install, simpler to maintain, and much

less costly to connect to control systems.

With traditional wired instruments, it’s necessary to run either

signal wiring for a loop-powered 2-wire instrument, or power and

signal wiring for a 4-wire instrument. This new wiring is very costly

to install, and many existing wiring drawings need to be updated.

The signal wiring needs to be connected back to the control

system, which can be very expensive, particularly if no spare I/O

points are available.

By utilising wireless technologies, measurement points

can be quickly deployed. No signal wiring is needed because

measurement information is transmitted via a wireless mesh

network, and no power wiring is needed because each wireless

sensor includes its own power module.

Wireless sensors have advantages, but wired sensors are often

used instead, particularly in real time control applications, and in

pump installations with easy access to wiring infrastructure such

as cable trays and wiring cabinets.

Benefits of pump monitoring

Outputs from these wired or wireless sensors are connected to

control systems, either at the pump station or in a central control

room. The sensors and control systems combine to provide a

number of benefits:

)

)

Reduces maintenance costs.

)

)

Enables proactive maintenance.

Figure 2.

Pump monitoring diagram. A wide variety of

parameters are typically measured on pumps used in pipelines,

some of which are depicted in this diagram.

76

World Pipelines

/

FEBRUARY 2016