proving information so measurement and asset management

specialists can provide reports, perform analytics, undertake

predictive maintenance on meters and transmitters, and decrease

pipeline downtime. This includes the ability to access information

electronically without adding equipment or placing greater burden

on field operators.

Improved pipeline metering solution

In order to optimise their calibration, test and certification

processes, and at the same time, reduce the cost of failed audits

and compliance tracking, oil and gas companies are employing

a new breed of pipeline metering solution. This technology

automates manual processes and tracks all of the required data to

meet regulatory requirements. In addition, it uses advanced logic

to determine meter proving schedules based on API guidelines.

An open, standardised pipeline measurement and meter

data management solution using Honeywell’s Uniformance®

Asset Sentinel helps measurement teams proactively keep

meters current with their provings, provers current with their

certifications, transmitters current with their verification and

calibrations, and test equipment current with their certifications.

Honeywell’s robust application enables pipeline personnel

to take control of proving schedule management/tracking,

recordkeeping, data input, calculations and reporting, alerts and

notifications, and enterprise access. With

this solution, utilising an interactive, real

time dashboard, they have the ability to:

)

Implement a single point for enterprise

visibility and near real time monitoring

of data from meters.

)

Schedule provings based on defined

criteria.

)

Automate storage of all proving data in

a single standardised format.

)

Summarise and report on proving,

certification and verification in the

current month.

)

Summarise the status of all meters, provers,

transmitters, and test equipment for a selected node.

)

Generate and publish measurement reports as

defined by the business.

)

Prepare bad actor reports by selected assets to

identify issues for continuous improvement.

)

Utilise real time trends and charts to troubleshoot

problems and analyse meter health.

)

Access proving data for search and analysis by

measurement specialists, analysts and management.

)

Leverage information in a central repository to

respond quickly to audits requests.

)

Integrate applications from multiple metering

vendors, applications and hardware.

)

Review and report on historical production performance.

)

Online asynchronous collaboration between various roles

(specialists and field operators).

)

Ability to track and maintain witness documents for third

party provings.

)

Ability to perform optical character recognition for data entry

where the flow computers are not connected to the SCADA.

This advanced solution for meter proving compliance and

tracking enables operations staff to work smarter – not harder.

For example, improved proving schedule management and

tracking allows the schedule for proving runs to be stored,

updated and adjusted based on actual meter factors. It also

provides a standard proving data record for various compliance

records that need to be managed. Data from various sources

can be converted into a standard format for greater ease of

use.

By capturing this data into an asset-centric monitoring and

calculation environment, users can benefit from a single source

of the truth or system of record for important meter and proving

information.

Figure 3.

Petroleum producers are required to manipulate vast quantities of meter

proving information.

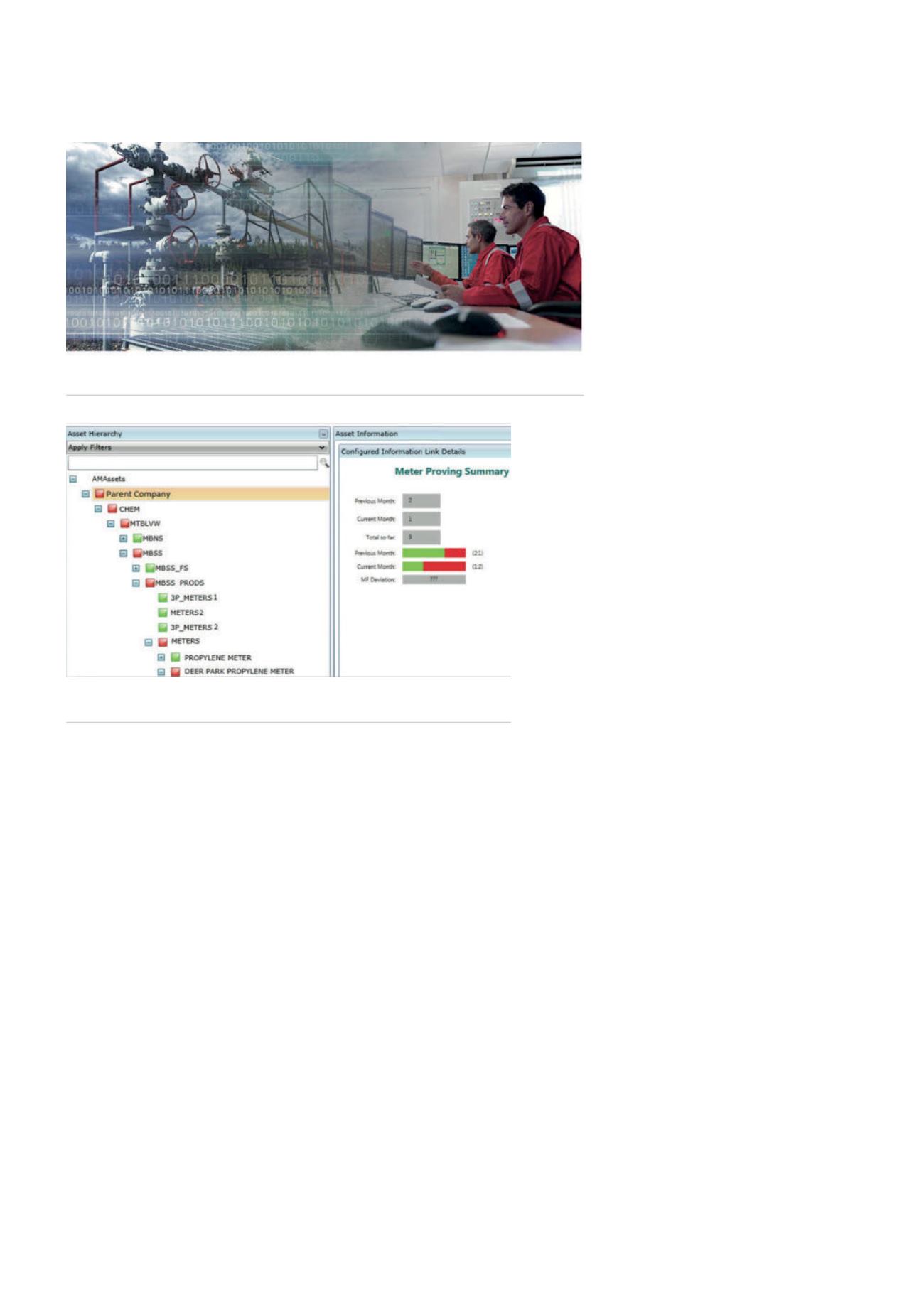

Figure 4.

Honeywell’s Uniformance Asset Sentinel accesses a real time,

historical data repository of information from a variety of plant systems.

72

World Pipelines

/

FEBRUARY 2016