)

Detailed planning and performance of integrity assessments

based on inspection and monitoring results and other

relevant historical information.

)

Detailed planning and performance of necessary mitigation,

intervention, and repair activities.

DNV GL’s recommended practice DNV GL’s recommended

practice can be referenced (DNV-RP-F116), and provides

recommendations for managing the integrity of submarine

pipeline systems throughout their lifecycle. As the basis for

this article, the DNV GL’s recommended practice should be

referenced. Reviewing these recommended practices will provide

the additional detail needed for each of the IM system steps.

Risk assessment and IM planning

Risk assessments are fundamental to

understanding the risks and threats posed to

the pipeline system. This process allows the

operator to focus on activities that prevent

and mitigate loss of containment. This also

helps to ensure that the safety level premised

in the design phase is maintained throughout

the life of the pipeline system.

Prior to calculating risk (which is the

product of the probability of an event and

its consequence) an operator must first

understand the potential threats to a subsea

pipeline and identify those that may impact

their pipeline system. Data and information

should be gathered and reviewed in order to

identify threats. A number of common threats

are considered for subsea pipelines; each of

them is categorised into the following six

groups:

)

Design, fabrication, and installation.

)

Corrosion or erosion.

)

Third party.

)

Structural.

)

Natural hazards.

)

Incorrect operation.

Different approaches are used to

assess pipeline risk. This can be evaluated

qualitatively and/or quantitatively (as is most

feasible). It is anticipated that additional

inspections and other kinds of data collection

(e.g. data gathered from monitoring) will

drive the subsea pipeline community towards

quantitative risk approaches and away from

qualitative and relative risk approaches. Still,

it is important to note that no matter which

approach is used, a documented procedure

must be followed and any deviations from the

procedure must be documented and justified.

The results of a risk assessment will drive decision-making

and long-term IM programmes. The programme justifies

which activities are performed, including why, how and when.

Minimum required integrity control activities are specified for the

different pipeline sections; this includes strategies for integrity

improvement activities. Simply put, the objective of an IM

programme is to provide:

)

A long-term plan (through inspection, monitoring, testing, and

integrity assessment activities) that verifies the behaviour of

the pipeline is in accordance with expected development

when compared to the predications established during

the design phase and/or previous assessments during the

operational phase.

)

A strategy that is prepared for handling any integrity issues

that require improvement through mitigation,

intervention and repair.

Inspection, monitoring and testing

IM programmes that are in accordance with

assessment of risk form the basis for detailed

planning of integrity control activities (i.e.

inspection, monitoring and testing).

Inspection and monitoring are both

considered condition monitoring activities.

These are executed to collect operational

data and condition indicators of a component.

Operational data can be physical data such as

temperature, pressure, flow, injection volume of

chemicals, or the number of operating cycles.

For submarine pipelines, the inspection

and monitoring programme normally covers

maintenance activities. Maintenance activities

can include cleaning (scraper pigs or chemical

treatment) or removal of external debris from

anodes prior to cathodic protection (CP)

measurements, as necessary. Generally, an

inspection monitors the physical state of a

component (for example wall thickness, damage

to the pipeline, coating defect, and pipeline

displacement), while monitoring is the collection

of relevant process parameters, which can

deliver indirect information about the condition

of a component.

In the context of IM of subsea pipeline

systems, testing typically includes system

pressure testing, testing of safety equipment,

pressure control equipment, over-pressure

protection equipment, emergency shutdown

systems, automatic shutdown valves, and safety

equipment in connecting piping systems. System

pressure testing is not normally applied as a

regular integrity control activity, however, in

some cases this may be considered.

Inspection, monitoring, and testing of

pipeline systems can be carried out with

different tools, or combinations of tools, having

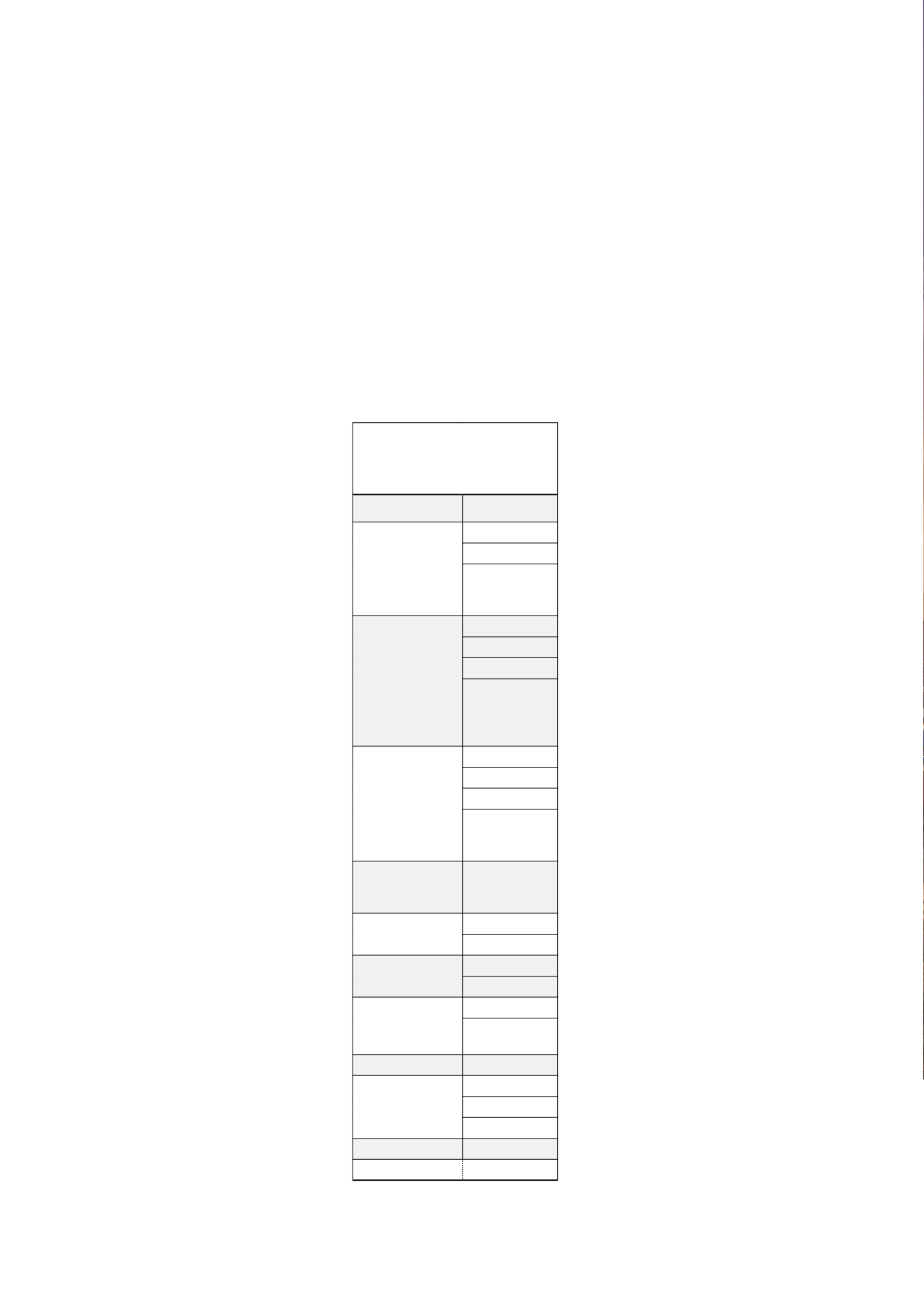

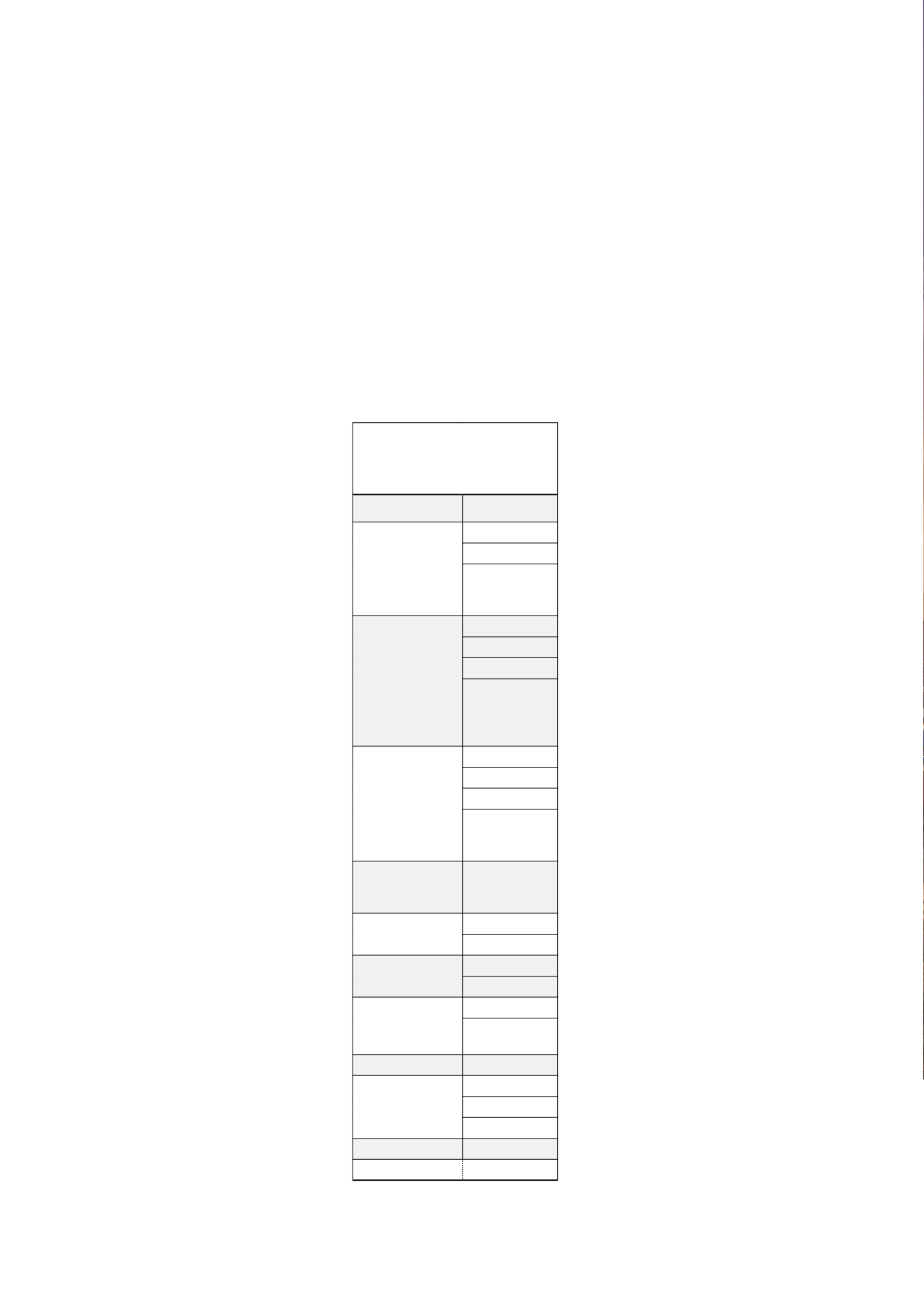

Table 1. Available assessment

codes for most common danage

or anomolies that impact subsea

pipeline integrity

Damage/anomaly Code/guideline

Metal loss

DNV-RP-101

ASME B31G

Pipeline defect

assessment

manual

Dent

DNV-OS-F101

DNV-RP-F113

DNV-RP-C203

European

Pipeline

Research Group

(EPRG)

Crack

DNV-OS-F101

DNV-RP-F113

BS-7910

Pipeline defect

assessment

manual

Gouge

Pipeline defect

assessment

manual

Free span

DNV-RP-F105

DNV-RP-C203

Local buckle

DNV-OS-F101

DNV-RP-F113

Global buckle

DNV-RP-F110

Germanischer

Lloyd Rules

Exposure

DNV-RP-F107

Displacement

DNV-OS-F101

DNV-RP-F109

DNV-RP-F110

Coating damage DNV-RP-F1-2

Anode damage

DNV-RP-F103

C

M

Y

CM

MY

CY

CMY

K

64

World Pipelines

/

FEBRUARY 2016