include temporary increased flowrate to flush out some

of the locally accumulated liquid or particles.

Pipeline intervention activities are typically actions related

to the external pipeline seabed interaction and support

conditions. Pipeline intervention is used to control thermal

axial expansion causing lateral or upheaval buckling, on-bottom

stability, protection against third party damage, to provide

thermal insulation, and/or to reduce free span length and gaps.

Typical means of intervention include:

)

)

Rock dumping.

)

)

Pipeline protections against third parties (mattresses, grout

bags, protection structures, gravel cover).

)

)

Trenching.

Pipeline repair is typically actions with the objective to

restore compliance with requirements related to functionality,

structural integrity, and/or pressure containment of the

pipeline system. The most suitable repair is dependent on

the extent and mechanism of the damage, pipe material, pipe

dimension, location of the damage, load conditions, pressure,

and temperature. The purpose of the repair is to restore the

pipeline safety level by reinforcing or replacing the damaged

section. A repair may be either temporary or permanent,

depending on the extent of the damage and method employed.

Below is a list of commonly used repair methods for subsea

pipelines:

)

)

The damaged portion of the pipe is cut out and a new

pipe spool is installed either by welding or by a mechanical

connector.

)

)

Local repair by installation of a repair clamp externally on the

pipeline.

)

)

Leaking flanges and couplings may be sealed by installing:

y

y

A seal clamp covering the leaking flange.

y

y

Installing a new coupling.

y

y

Increasing the bolt pre-load.

y

y

Replacing gaskets and seals.

Conclusion

While continuous operation of strategically critical subsea pipeline

assets is paramount, unplanned release and downtime can also

introduce adverse consequences related to the environment, public

safety, legal liability, regulatory scrutiny, and public relations.

A well-planned, dynamic and comprehensive IM plan is

proven to be a critical tool for the subsea operator to ensure safe,

continuous and extended operation of the asset.

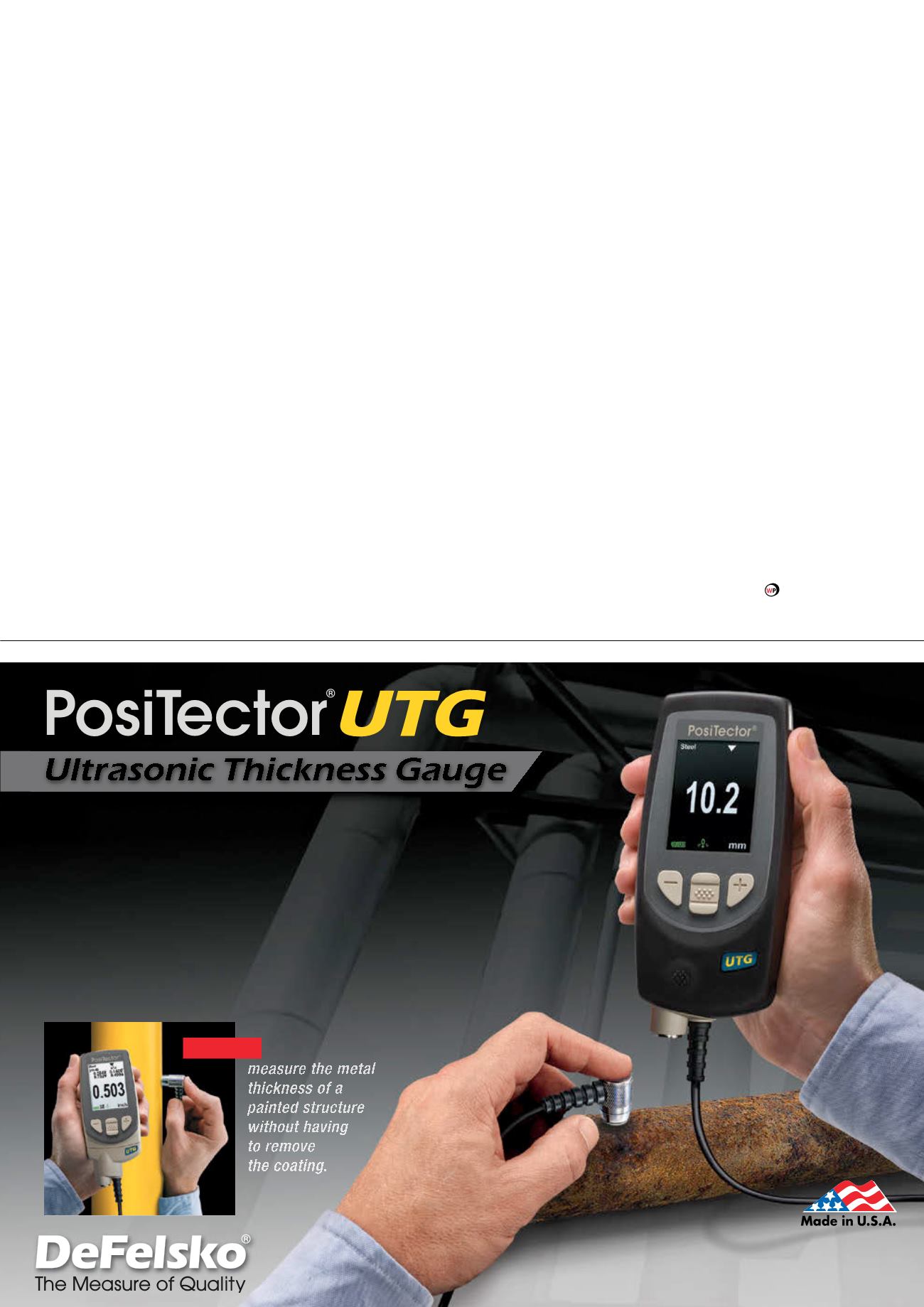

DeFelsko Corporation

Ogdensburg, New York USA • Tel: +1-315-393-4450

Fax: +1-315-393-8471• Email:

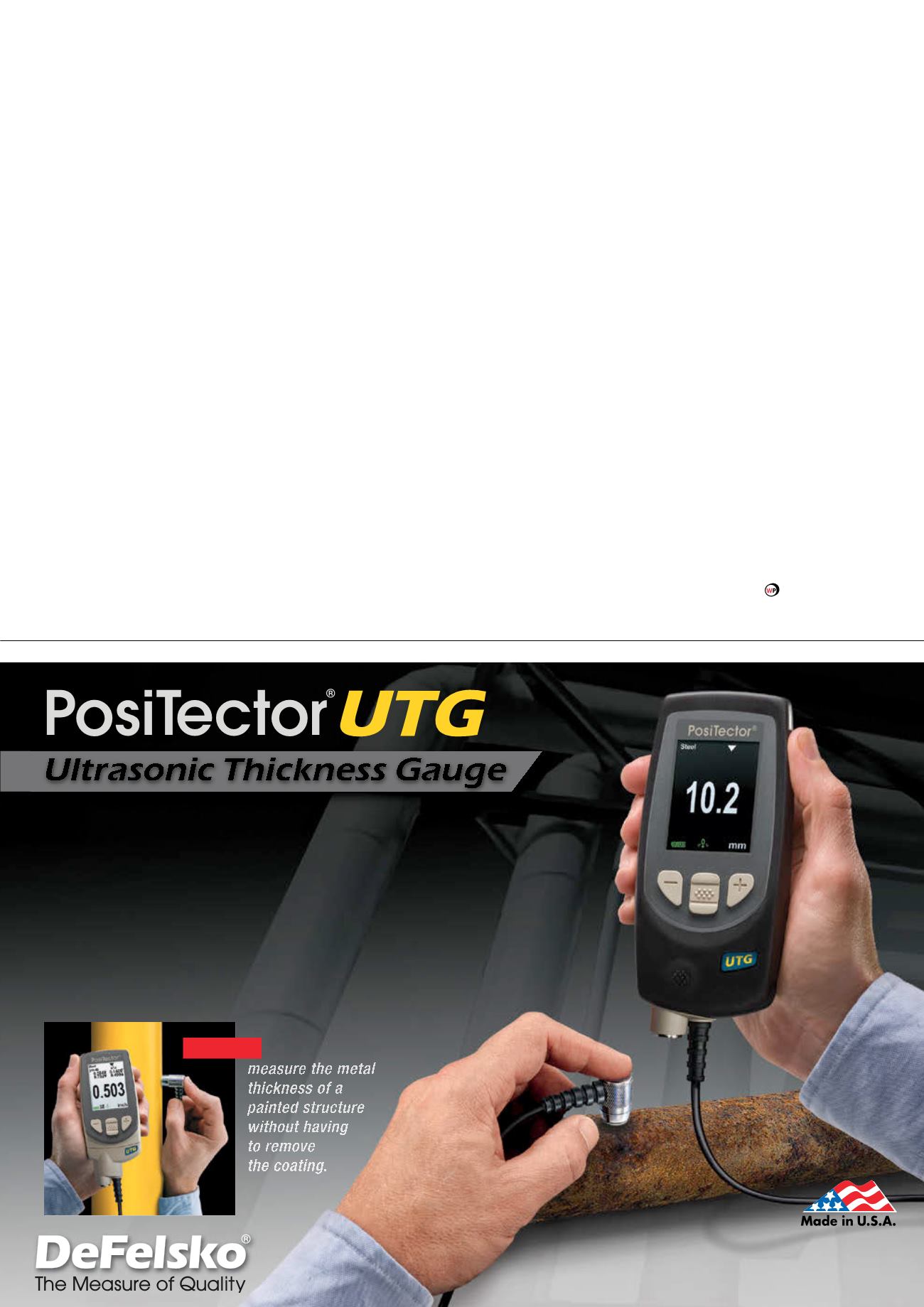

Choose Standard or Advanced features and Corrosion or Thru-paint probe

Advanced models include A-scan, B-scan, and Screen Capture

All models include memory, statistics, USB

Accepts coating thickness, environmental and surface profile probes

UTG M

Thru-Paint models

Ideal for measuring wall thickness and the effects

of corrosion or erosion on pipes, tanks or any

structure where access is limited to one side.

33

m

74

k 28

c 33

m

74

k 28

w

33

m

28

c

28

w

Ultrasonic Thickness Gauge

UTG_Ad_210mmX146mm 1/15/16 10:21 AM Page 1