With enhanced calculation and reporting capabilities, it is

possible to perform necessary calculations, view the proving

schedule, and trend and display meter factors. These solutions

also automate the proving reporting process, with information

automatically pulled into appropriate databases so there is no

lag time from when proving is done and field operators pass off

reports for use by specialists.

Improved technology for alerts and notifications makes

problems immediately visible so appropriate actions can be taken.

Personnel gain insights into both successful and failed proving

runs, and can accurately predict asset maintenance requirements

to prevent pipeline shutdowns. Alerts notify users when a proving

is complete and there is a shift in meter factor.

Lastly, proving compliance and tracking information can

now be provided in an integrated system with enterprise access

available to a variety of users – from management, to the

measurement team, field technicians, and engineering department.

This enables diverse stakeholders to access critical data to

improve their performance. Security and permission is based on

the user’s role so they only view information relevant to their job

function.

Benefits to end users

Thanks to ongoing innovations in meter data management

technology, pipeline operators are able to effectively manage the

maintenance and calibration of pipe provers and meter proving

across commodities by performing robust trend analysis and

analytics on proving data.

The specific benefits to end-users include:

)

)

Effective information management made possible by a single

source of the truth, combined with improved data quality,

integrity, availability and security.

)

)

Enhanced operational efficiencies through increased uptime

and reliability; improved proving schedule visibility; faster

detection of equipment problems; and increased visibility of

the frequency of commodity change, volume and flowrate.

)

)

Prevention of unplanned shutdowns resulting from meter

proving issues and failures.

)

)

Greater employee productivity (up to 10% reduction in meter

proving activities) due to an infrastructure that supports

improved work processes, reduces the time required for

meter proving activities, expands data access, automates trend

analysis, and minimises reporting effort.

)

)

Improved safety and regulatory compliance enabled by real

time visibility of meter/pipeline reliability, as well as pipe

volumes and materials for incident management.

)

)

Effective tracking of audit records to demonstrate compliance.

)

)

Reduction in the time needed to meet audit requirements.

)

)

Reduction in fines, which could represent thousands of dollars

per incident.

)

)

Avoidance of lawsuits potentially costing millions.

)

)

Protection of company image and reputation.

Experience in the field has shown that an improved

pipeline metering solution can significantly reduce the costs

associated with proving data manipulation. It can also shorten

the time required for a typical proving, and as such, minimise

labour hours. Increased visibility into meter and pipeline

reliability prevents system downtime, and operators can better

detect prover anomalies and poor measurement performance.

Overall, enhanced pipeline metering and measurement

technology is the answer to lowering the cost of audit findings,

avoiding penalties for failed audits, and reducing the potential for

legal action stemming from inaccurate custody transfer.

Conclusion

Automation suppliers have developed

powerful, scalable applications to help oil

and gas companies overcome the challenge

of accessing data from multiple sources and

turning it into actionable information. Aside

from improvements in pipeline meter proving

compliance and tracking, these solutions can

address many aspects of equipment health

monitoring and asset management. They provide

an integrated environment where users can

view and assess different types and classes

of assets across the enterprise – calculating

and monitoring equipment efficiency and

reliability, and ensuring a low cost-of-ownership

throughout the asset lifecycle.

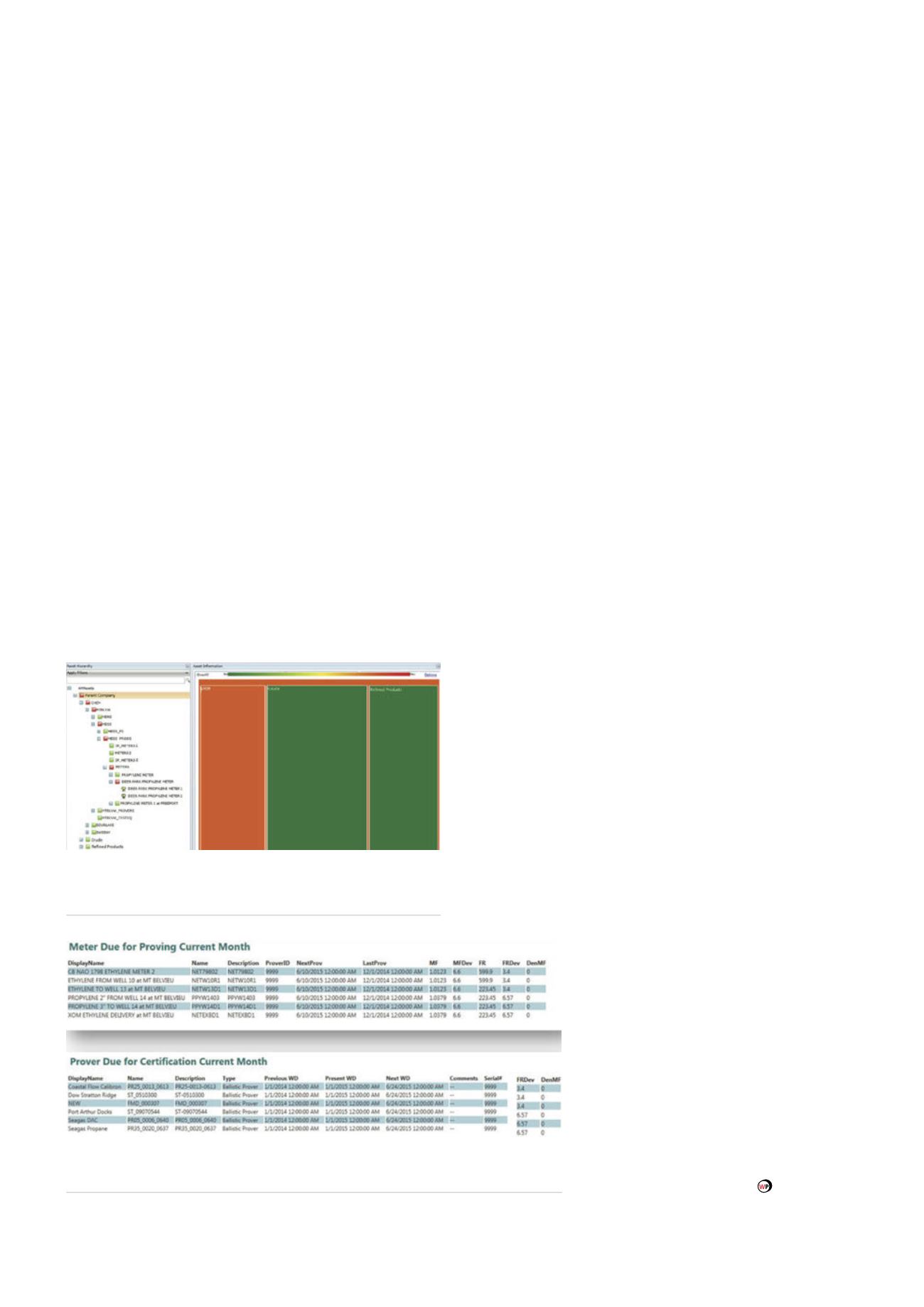

Figure 6.

Proving schedule management and tracking capabilities allows the

schedule for proving runs to be stored, updated and adjusted based on actual

meter factors.

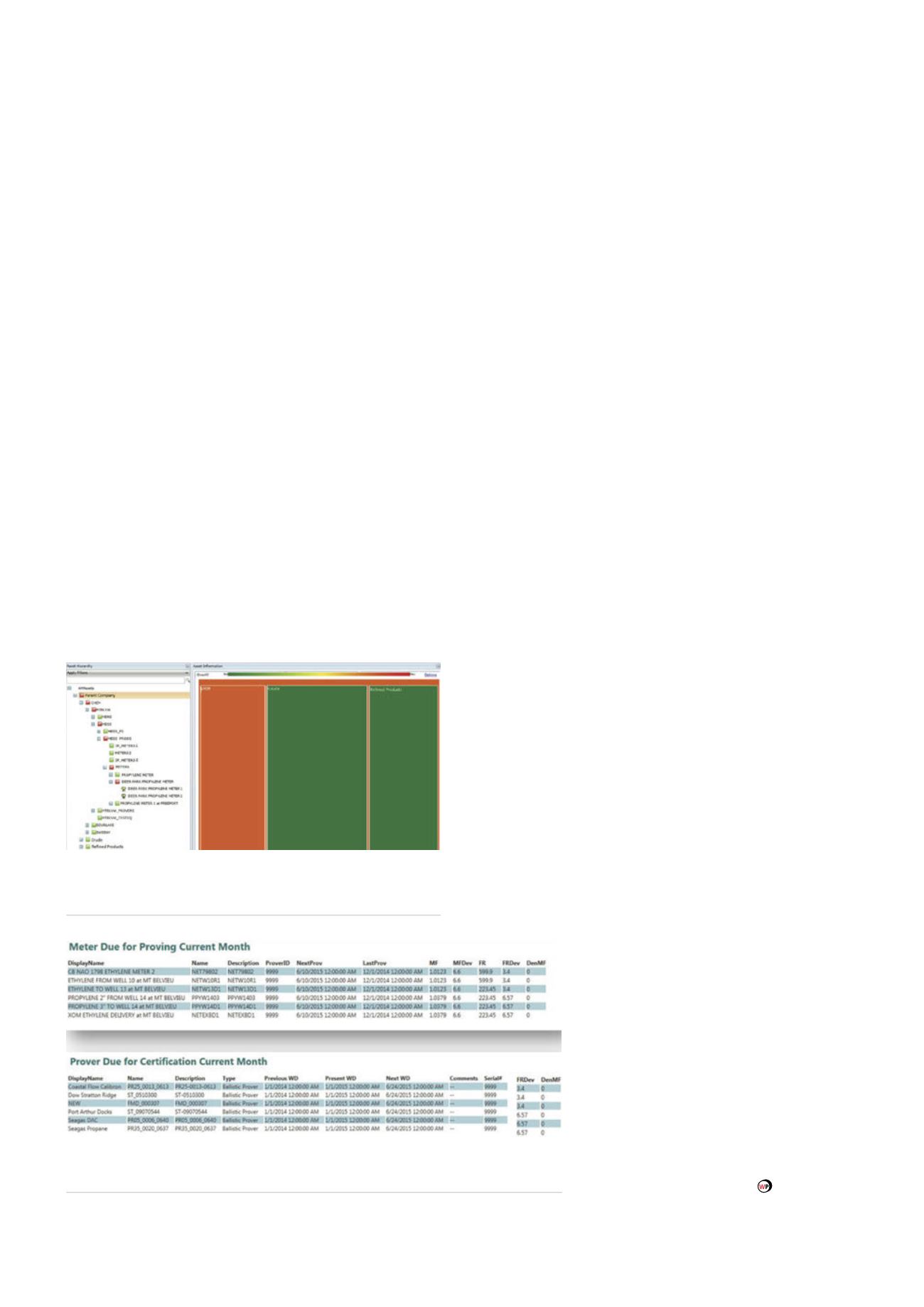

Figure 5.

Improved technology for alerts and notifications

makes problems immediately visible so appropriate actions can

be taken.

74

World Pipelines

/

FEBRUARY 2016