are not exceeded, and the process does not require special

materials to combat corrosion.

However, it is generally acknowledged that globe

valves contain inherent cavities that can easily promote

contamination and allow slurry material to become entrapped

in the body of the valve, disabling the valve operation. This

often prevents globe valves being specified for high purity or

slurry systems.

Applying anti-corrosion coatings

In order to provide corrosion or erosion protection to the

internal surfaces of the valve, the designer has the options

of either manufacturing the valve out of solid corrosion

resistant alloy (CRA) or by specifying the application of

a weld overlay clad layer onto the wetted surfaces. The

former option can become very expensive,

especially when considering the larger (12 in.

NB plus) and higher pressure rating valves. In

these cases it is generally considered more

cost effective to produce the valve bodies

and bonnets from carbon manganese or low

alloy steel and clad the wetted surfaces with

a CRA, which is best suited for the medium

and service to which the valve will be put.

As globe valves are castings, and

therefore able to be made into any shape

the customer wants, designers generally

try to keep the inlets and outlets at a

constant cross sectional area so that the

flow is uniform. This means valve inlets are

circular to match incoming pipework, before

changing to an elliptical or square section of

the same cross-sectional area, which keeps

the valve dimensions compact. When a globe

valve is cast, the internal shapes do not need

to conform to any axis, thereby causing

major challenges to the application of weld

overlay cladding to the internal surfaces.

Indeed the application of cladding needs

to deposited on surfaces which cannot be

directly viewed and in all welding positions

including overhead.

Whilst it can be difficult to apply

anti-corrosion coatings to the internal

surfaces of castings, a leading weld overlay

cladding specialist Arc Energy Resources has

successfully applied its specialised coatings

to globe valves for a number of different

companies and has, more recently, developed

special techniques with the co-operation

of globe valve manufacturers to apply

the coatings more cost effectively. These

techniques are also dramatically improving

the protection performance of the valves.

Commenting for Arc Energy Resources,

Managing Director Alan Robinson says: “We

have been applying corrosion-resistant

coatings to equipment in the oil and gas

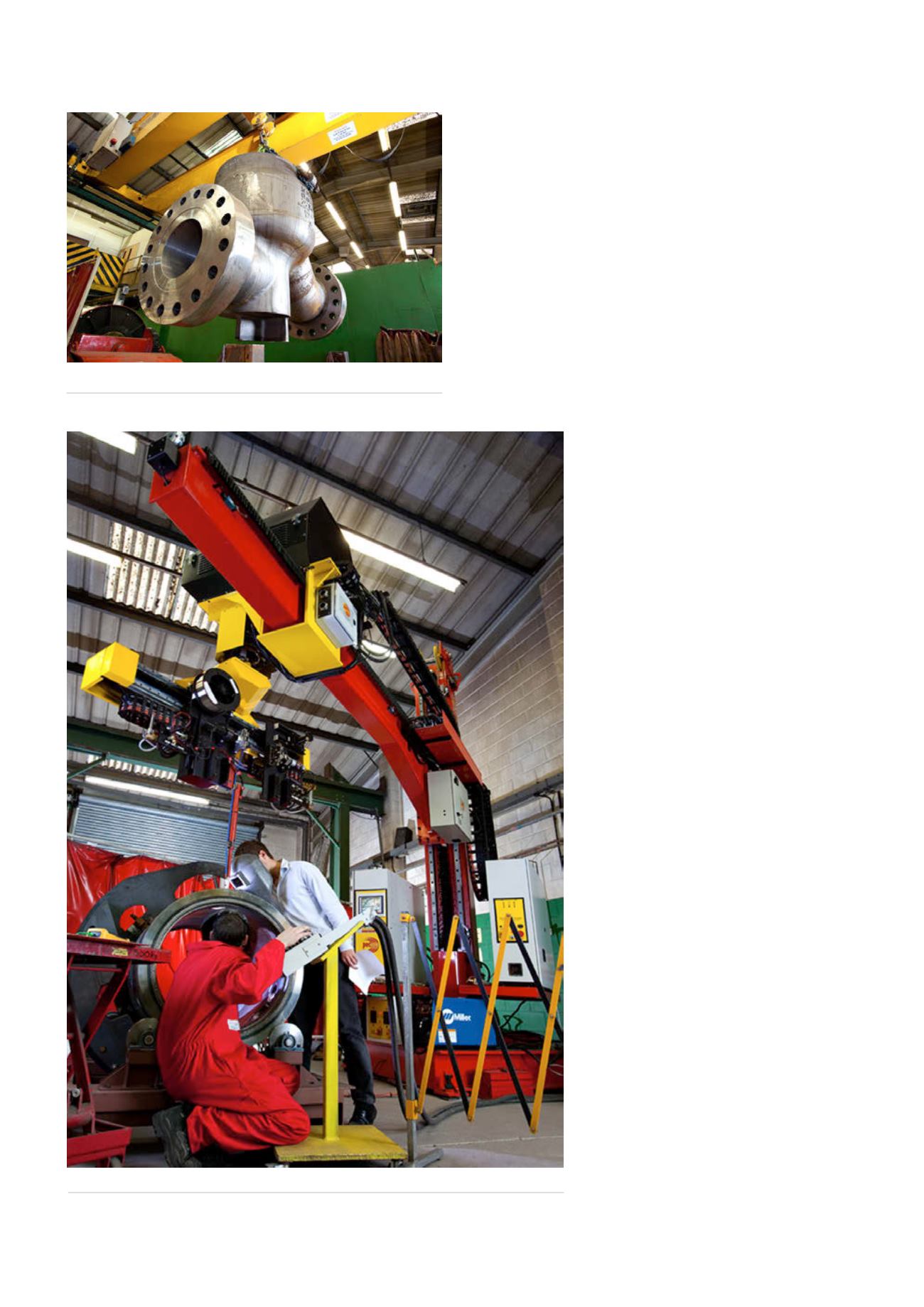

Figure 1.

Globe valve being positioned to commence cladding.

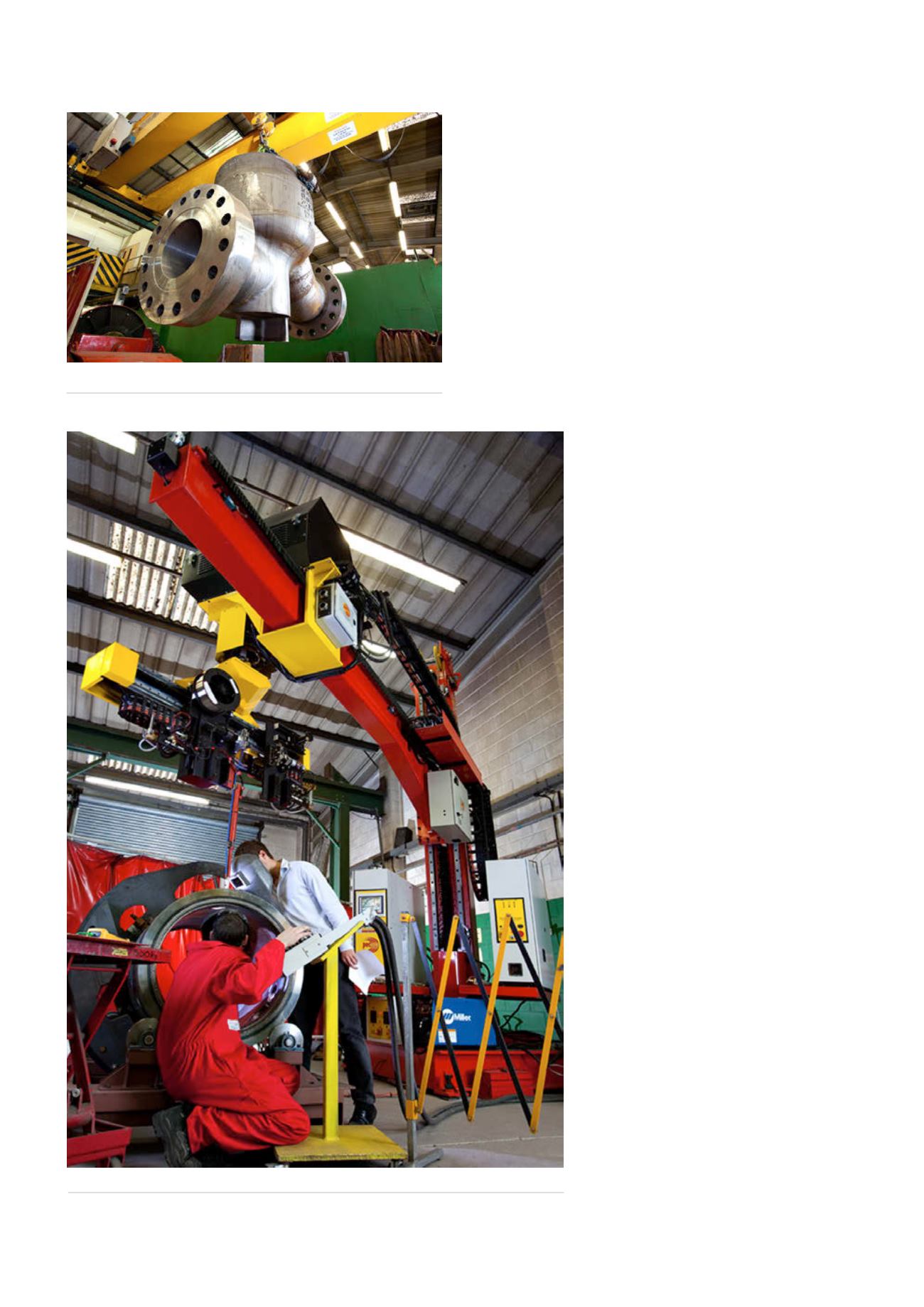

Figure 2.

Rotary head in operation.

82

World Pipelines

/

FEBRUARY 2016