different capabilities and areas of application. Below are the most

common tools and tool carriers used to inspect subsea pipelines:

)

)

General visual inspection (GVI) is the visual inspection carried

out by remotely operated vehicles (ROVs) or divers. GVI

does not include any cleaning but will reveal most external

condition threats to the pipeline.

)

)

Extended visual pipeline survey is a form of inspection that

uses a pipeline work class ROV. Normally this includes 3-view

digital video digital camera, seabed transverse profiles, CP,

and a depth of pipe tracker. This type of survey reveals the

same types of anomalies as GVI with the addition of detailed

span profiles and depth of burial.

)

)

Close visual inspection is a detailed inspection of a specific

area using either a diver or a work class ROV.

)

)

High precision survey is a highly accurate positional survey

that determines the absolute position and relative year-to-

year lateral movement of the pipeline on the seabed.

)

)

Inline inspection (ILI) is an intelligent pigging of

the pipeline utilising various non-destructive

testing (NDT) methods. This measures continuous

end-to-end wall thickness loss and pipeline

anomalies.

)

)

Monitoring evaluates the pipeline using

corrosion probes, impressed current system,

process parameters, fluid composition, chemical

injections, and monitoring of loads, stresses,

strains, displacements, or vibrations.

)

)

Testing looks at the system or function testing of

equipment or control system.

Integrity assessment

IM programmes determine the need for planned

integrity assessments. That said, potentially

unacceptable damage or an abnormality may be

observed or detected, and an integrity assessment is

required to evaluate the damage, or abnormality,

and the possible impact on integrity.

Integrity assessments, planned or unplanned, are most

commonly categorised as follows:

)

)

Corrosion assessments covering internal and external

corrosion.

)

)

Mechanical assessments covering fatigue in free spans, fatigue

in buckles, displacement that causes damage, displacement

that causes overstress, or third party damage causing extreme

strains. The effects of environment on cracking should also be

considered.

An IM programme typically specifies applicable assessment

codes for various types of damage or abnormality. Table 1

provides an overview of available assessment codes for the

most common damage or anomalies that impact the integrity of

subsea pipelines.

Mitigation, intervention and repair

The main activities related to mitigation, intervention, and repair

generally include detailed planning of the operation, technology

qualification, and (if necessary) the mobilisation, execution of the

operation, and documentation. Mitigating activities are, for the

most part, measures related to the internal pipeline condition.

Typical means of mitigating activities are:

)

)

A restriction in operational parameters such as maximum

allowable operating pressure, inlet temperature, flowrate,

and number of given amplitudes of these. Such restrictions

may have an impact on the set-point value for the pressure

protection system or the pressure regulating system.

)

)

Use of chemicals to inhibit corrosion, improve flow,

reduce scaling, or avoid hydrate formation.

)

)

Maintenance pigging with the objective of removing scale,

deposits, liquid accumulation in sag bends. This could

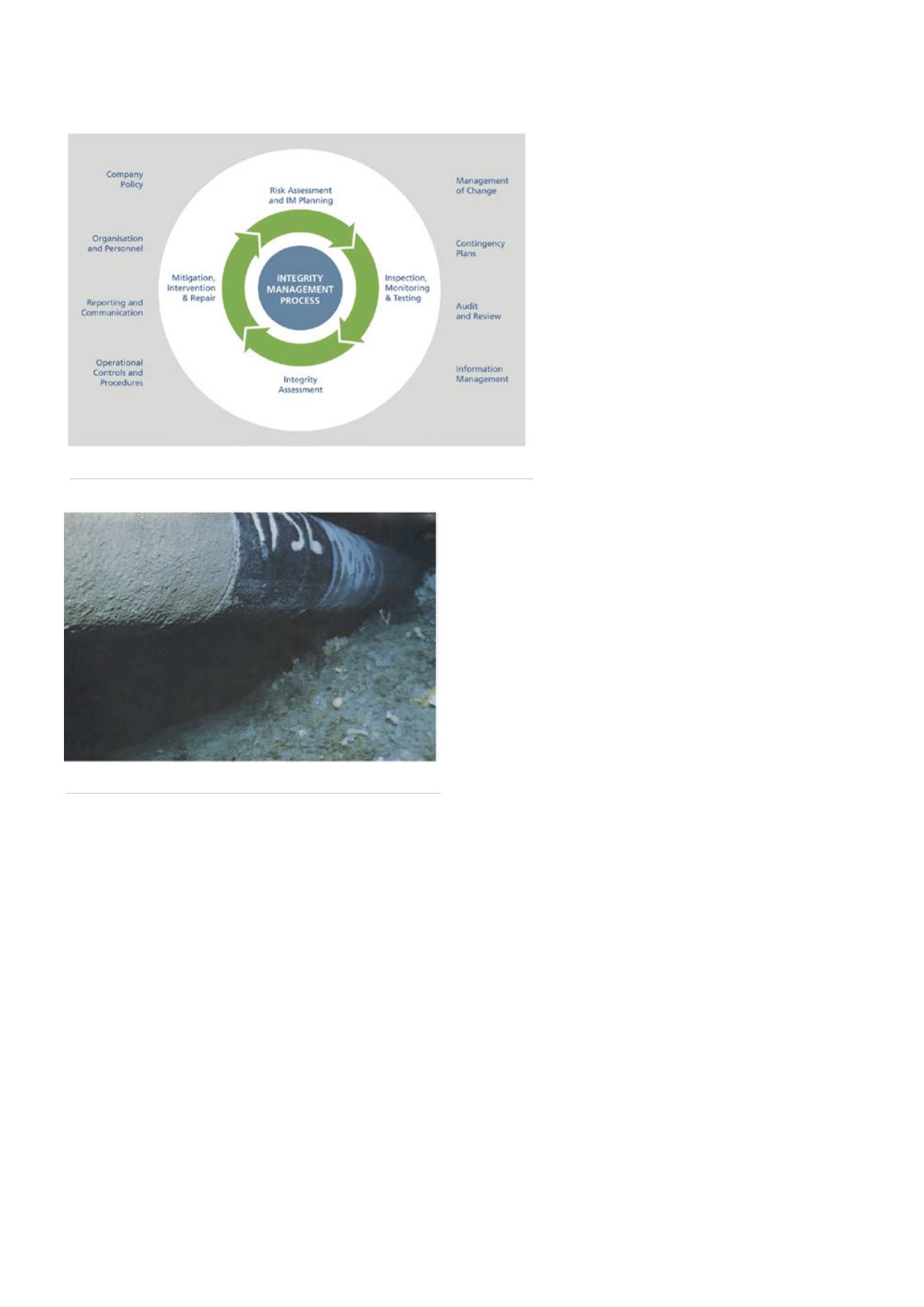

Figure 2.

Submarine pipeline under free span.

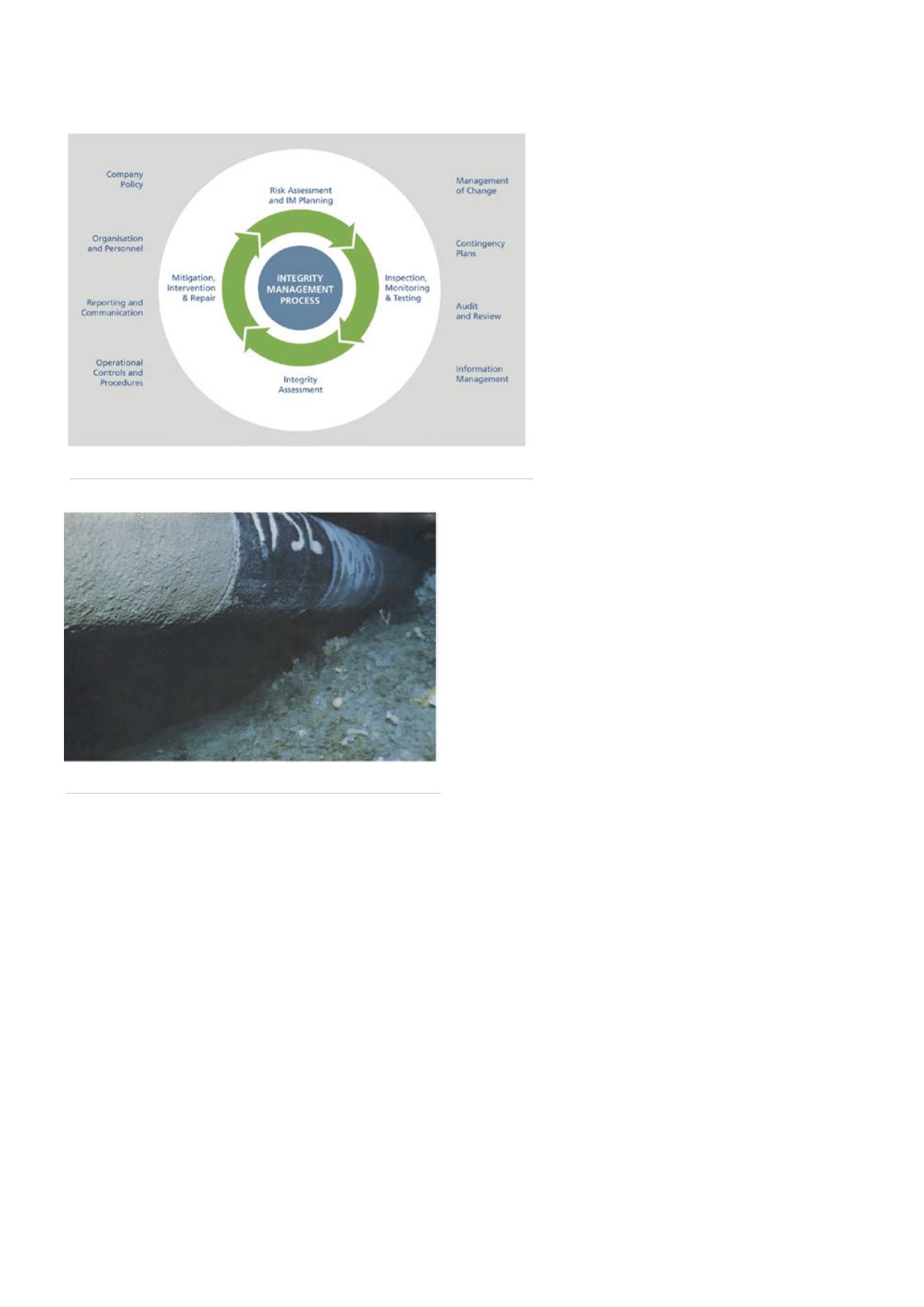

Figure 1.

IM system.

66

World Pipelines

/

FEBRUARY 2016