pipeline free span monitoring study in the Gulf of Thailand.

The deployment period lasted six months, and involved

monitoring a number of potentially high-risk pipeline free

spans, which were longer than the code, defined allowable

limits.

The solution

The free span monitoring kit was deployed on a selection

of spans across a range of pipeline diameters. The data

recovered showed that the pipeline free spans were

not experiencing VIV, despite the local environmental

conditions being in the range predicted by the analysis

to excite the span. Using the data collected and further

analysis taking account of the identified conservatisms, the

span anomaly limits were modified accordingly.

The benefits

The project confirmed that the pipeline free spans were

not a threat in their current state and gave the operator

the data needed to assess the acceptability of any future

free spans identified. Future free span lengths can be

compared to the calculated maximum allowable length

for each section of pipeline. Without this in situ data,

the free span would have been marked for remediation.

Equipped with this knowledge, the operator was able to

focus on the free spans that presented a risk and avoid

unnecessary and costly remedial works on the other

pipeline sections.

Span assessments in lifetime extension

As well as forming a fundamental part of pipeline design

and integrity management, free span assessments are also

a staple feature of pipeline lifetime extension studies. Free

spans are normally identified as a threat to a pipeline’s

extended life during the risk assessment stage. Fatigue

damage has often accumulated throughout the pipeline’s

20 - 25 year life, and the pipeline strength may have been

compromised during the period of operation to date –

the wall thickness of the pipeline may have been

reduced due to corrosion for example.

Jee draws upon its expertise in pipeline design

and integrity management to compliment the free

span assessments performed as part of the lifetime

extension process. The company understands how

the design codes have changed over the decades

of pipeline operation, and know where extra

conservatism has been added or removed. They also

have an appreciation of the code’s limitations, so

its engineers are able to effectively challenge them

without adversely affecting safety, maximising the

allowable extension to pipeline operating life. As

part of this process, free span anomaly limits may

be updated based on the results of the analysis

performed.

Summary of span services

Jee’s engineers have conducted thousands of

free span assessments using a combination of

calculations and numerical methods, such as FE

analysis and computational fluid dynamics (CFD)

to investigate, predict and solve potential and

existing spanning issues. This experience covers the

assessment of free spans in single pipe and more

complex solutions, such as pipe-in-pipe systems and

bundles.

In addition to its analysis based approach,

Jee has developed a unique free span monitoring

system in order to bridge the gap between the

assessments performed in accordance with

the available recommended practices for span

assessment and the ‘real world’ behaviour of the

span. This has allowed it to justify the continued

operation of pipelines with significant free spans

without the need for costly remediation and

the associated future integrity concerns that

remediation may bring.

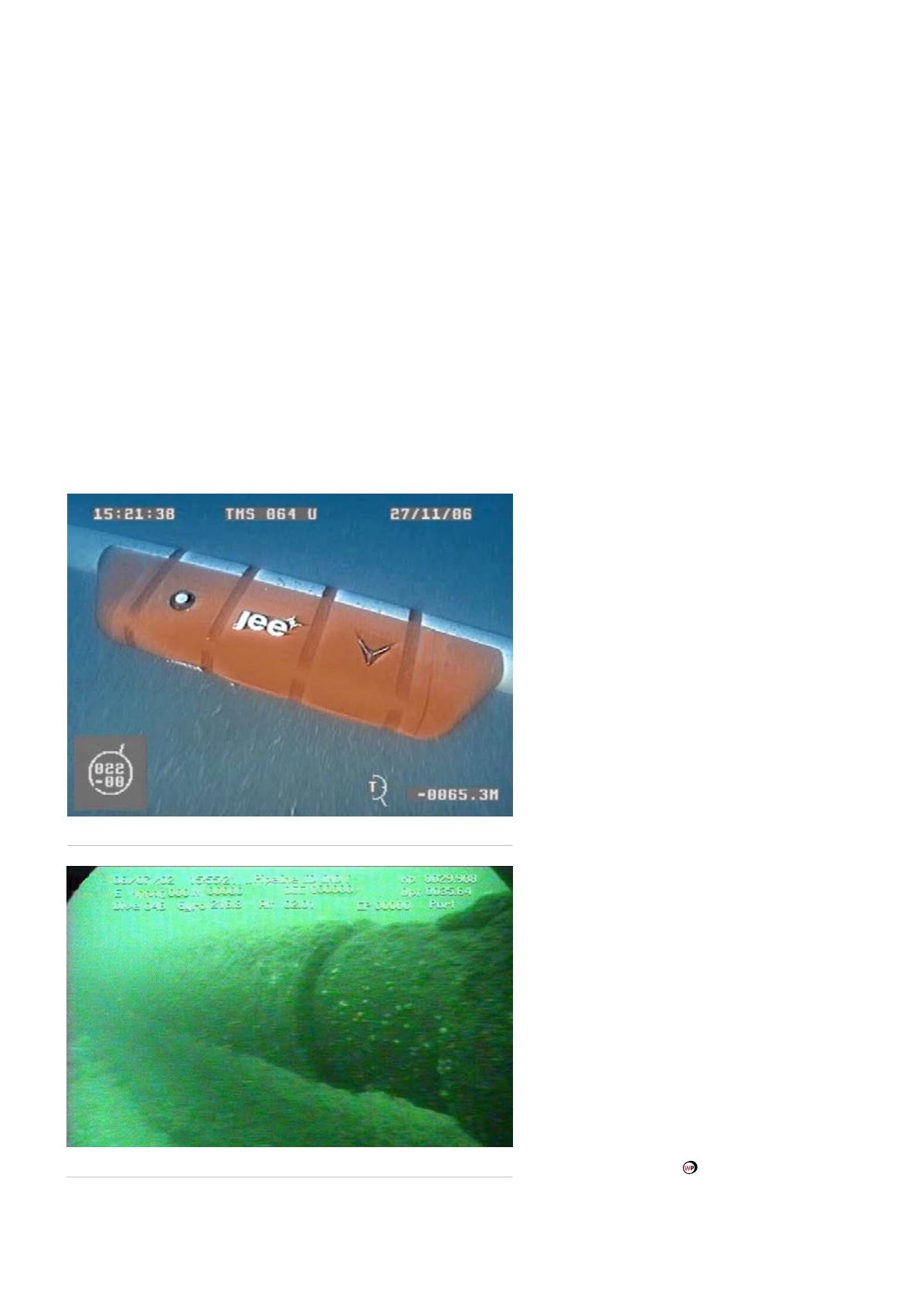

Figure 3.

Jee’s span monitoring system.

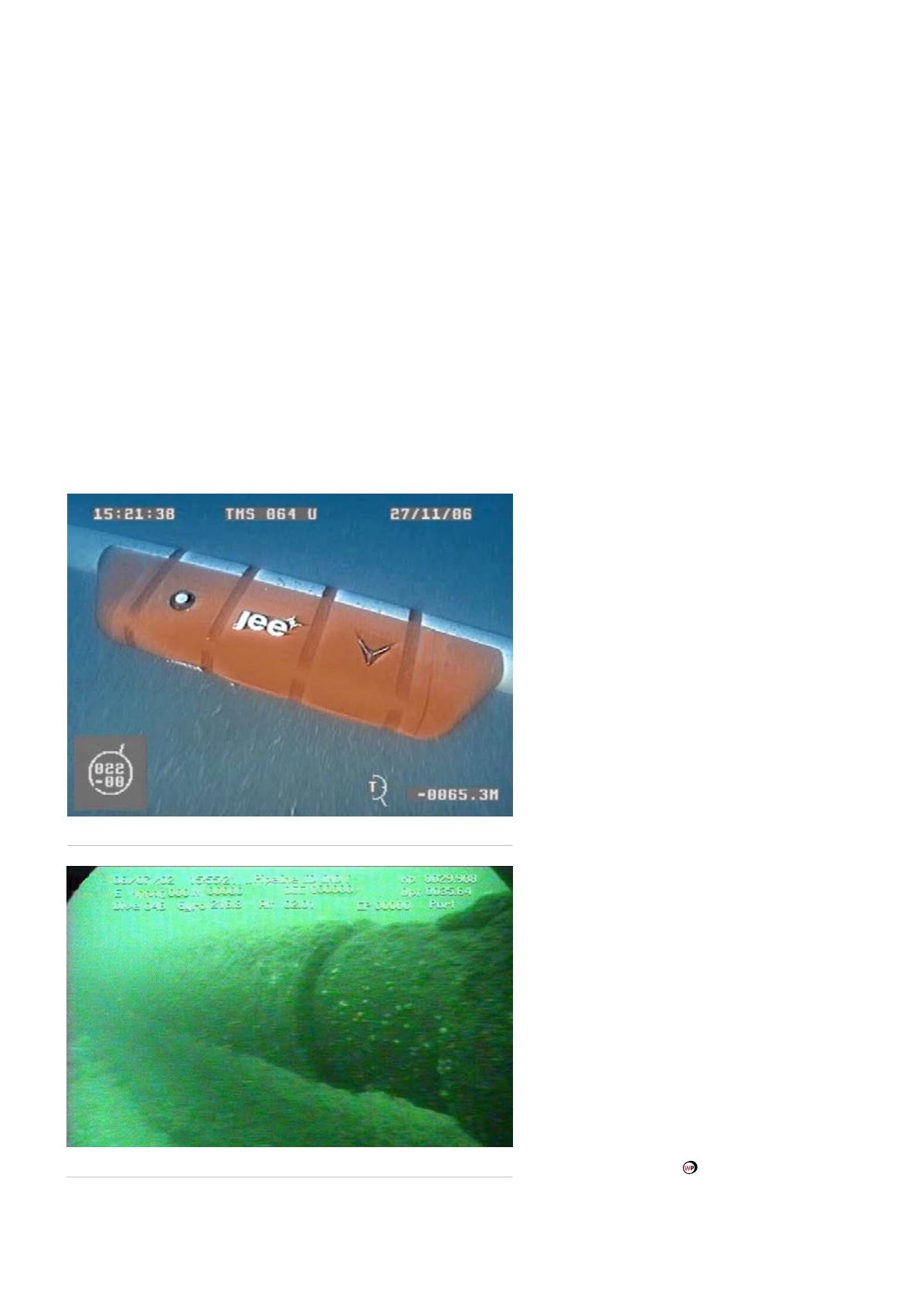

Figure 4.

Free span identified during survey.

54

World Pipelines

/

FEBRUARY 2016