support points, small bore connections, valves, and finally,

supporting structure.

In some ways ODS analysis resembles modal analysis,

which is concerned with the natural frequencies and

mode shapes of multiple DOF systems, however, the main

differences with ODS are as follows:

)

)

Modal analysis will identify all modal responses of the

system that could ‘potentially’ be excited.

)

)

ODS will identify only those modal frequencies, which are

being excited at that time.

)

)

ODS will also identify any other vibration mode shapes

caused by forced excitation i.e. not occurring at a

structural natural frequency.

Causes of the consequent excessive vibration vary, but

may include: forces generated by the item itself, inadequate

support systems, unbalances, and external loads.

In ODS analysis, the degree of vibration in an item is

measured and clearly visualised using specialist software,

making the decisions connected with maintenance, adjustment

and optimisation much better informed and more likely to

succeed than may otherwise have been the case.

Who needs ODS analysis, and why?

A powerful tool that permits the clear and detailed

visualisation of vibration, ODS can be used to pinpoint

problems in a range of machinery, tools and structures,

particularly those involving periodic excitation, and in a

number of industrial and engineering settings. What is more,

ODS analysis can be carried out while the plant is in operation,

so there is no downtime – this is often a particular advantage

in manufacturing environments.

The key advantages of timely ODS analysis include, but are

not limited to:

)

)

A powerful tool for vibration trouble-shooting.

)

)

A means of capturing a complex vibration baseline for

comparison against future surveys.

)

)

Increased equipment longevity (for example, by reducing

the damage caused by fatigue).

)

)

Increased productivity (mainly through reductions in

equipment failure, increased equipment efficiency, less

downtime for unplanned maintenance).

)

)

Assured compliance with environmental, legal and

regulatory requirements.

)

)

Detailed information about equipment performance

and status, which allows managers to make appropriate

decisions about equipment lifecycles, repair and

investments.

The unplanned maintenance of equipment and related

structures, such as piping and support systems, is often

responsible for significant disruption and thus production

losses, so it makes sense for manufacturers to turn to a

specialist partner to complete ODS analysis, such as AVT

Reliability.

Such partnerships give manufacturers and others not only

access to expertise in ODS analysis, but also to the company’s

ability to generate, present, model, and enact appropriate

solutions. AVT Reliability uses ODS analysis to identify areas

of concern and to provide comprehensive guidance regarding

possible changes and their outcomes. That way, ODS analysis

can be used to solve the problems caused by excessive

vibration before they cause major – even catastrophic –

issues, and helps the client to make fully informed, pragmatic

decisions about investment, modifications and the lifecycles

of their equipment.

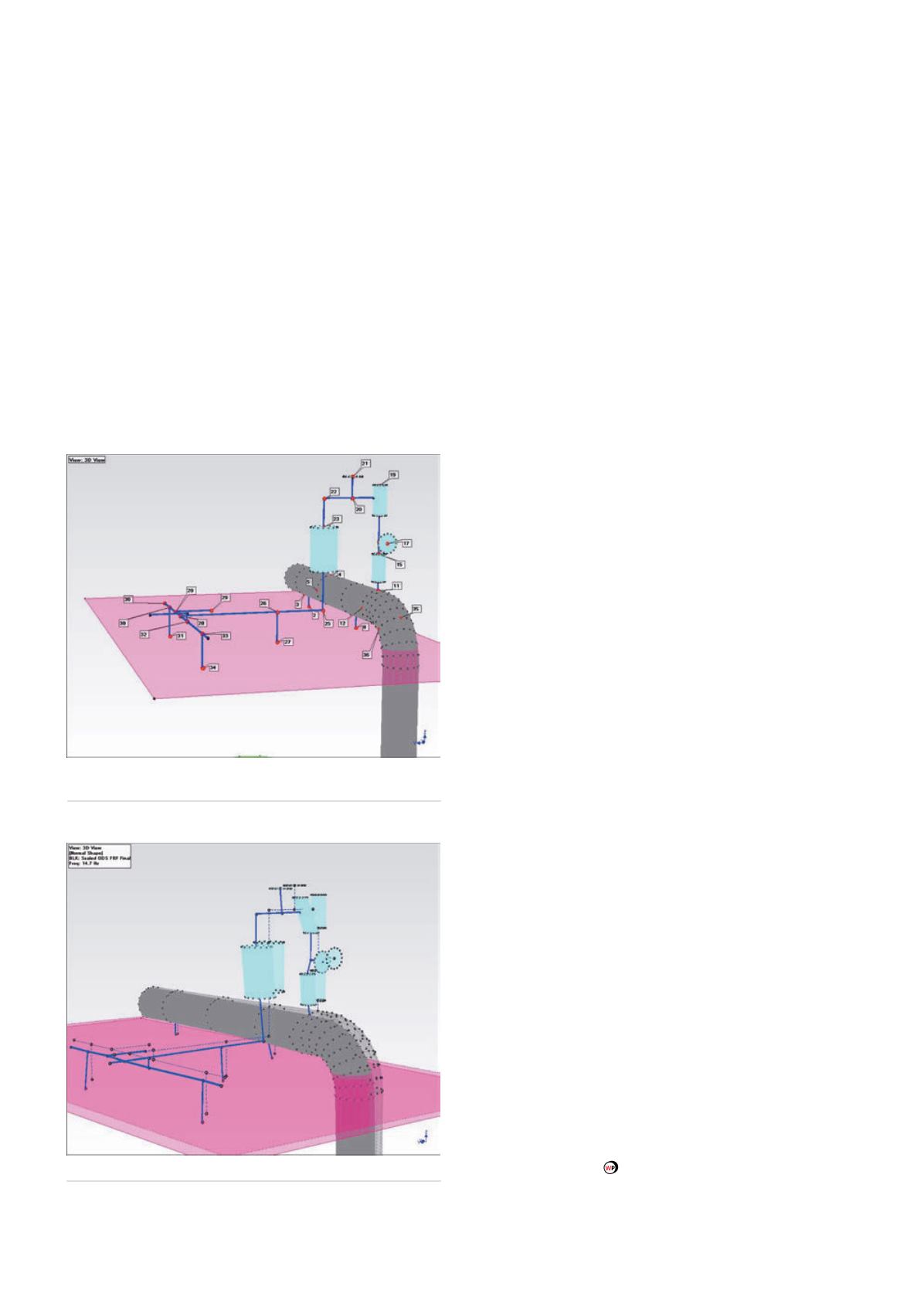

Figure 4.

Showing ODS results.

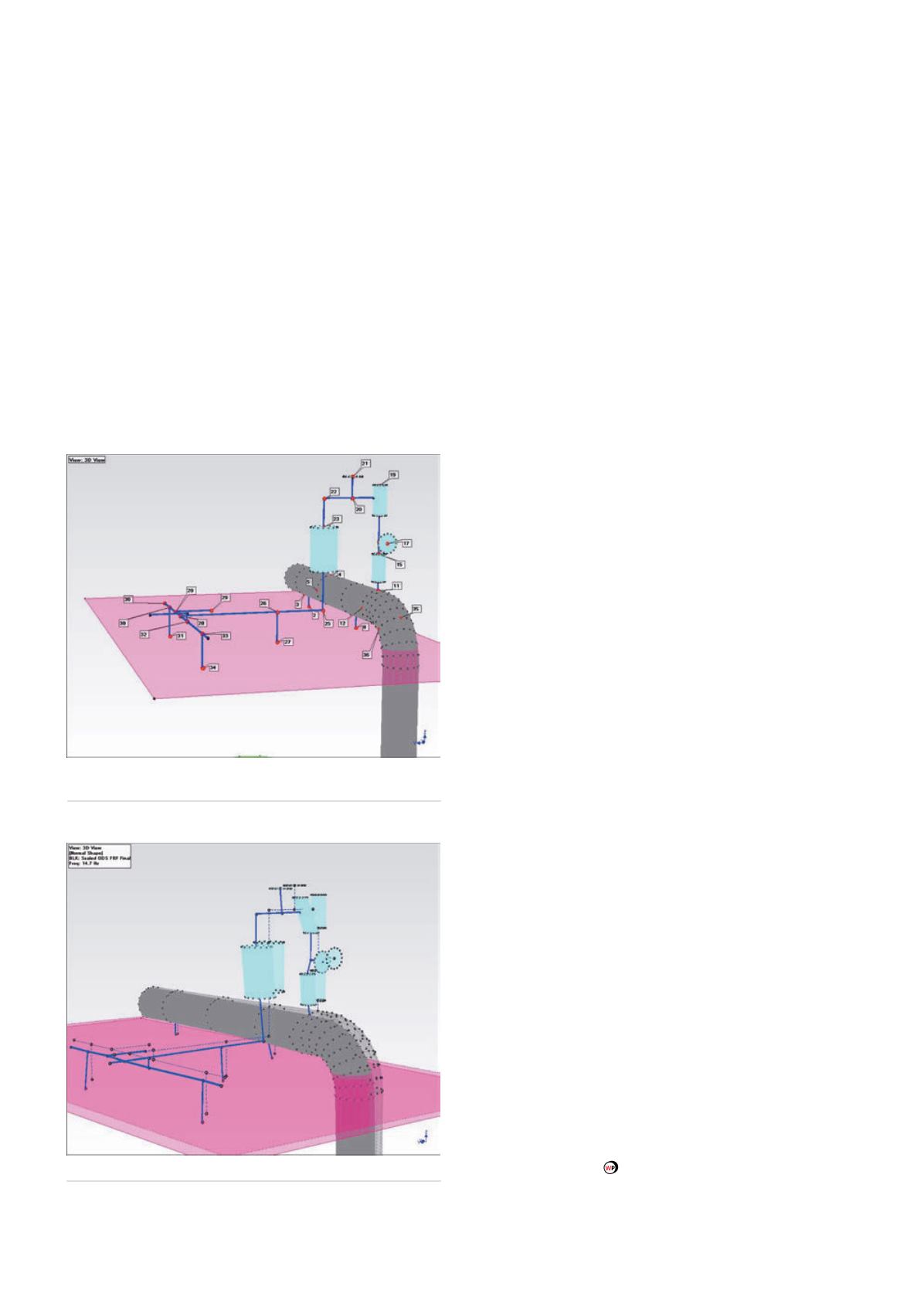

Figure 3.

ODS Plot showing measurement locations of the

‘zoomed in’ section.

50

World Pipelines

/

FEBRUARY 2016