These documents contain all the information required for

the field engineers performing the excavation, including the

co-ordinates of the defect, its exact clock position on the

pipe, the distance to the downstream and upstream markers

and valves, and the angular position of the longitudinal welds

for targeted and neighbouring joints. This allows engineers to

find the exact location of excavation and be able to identify

the defects to be repaired.

Run comparison

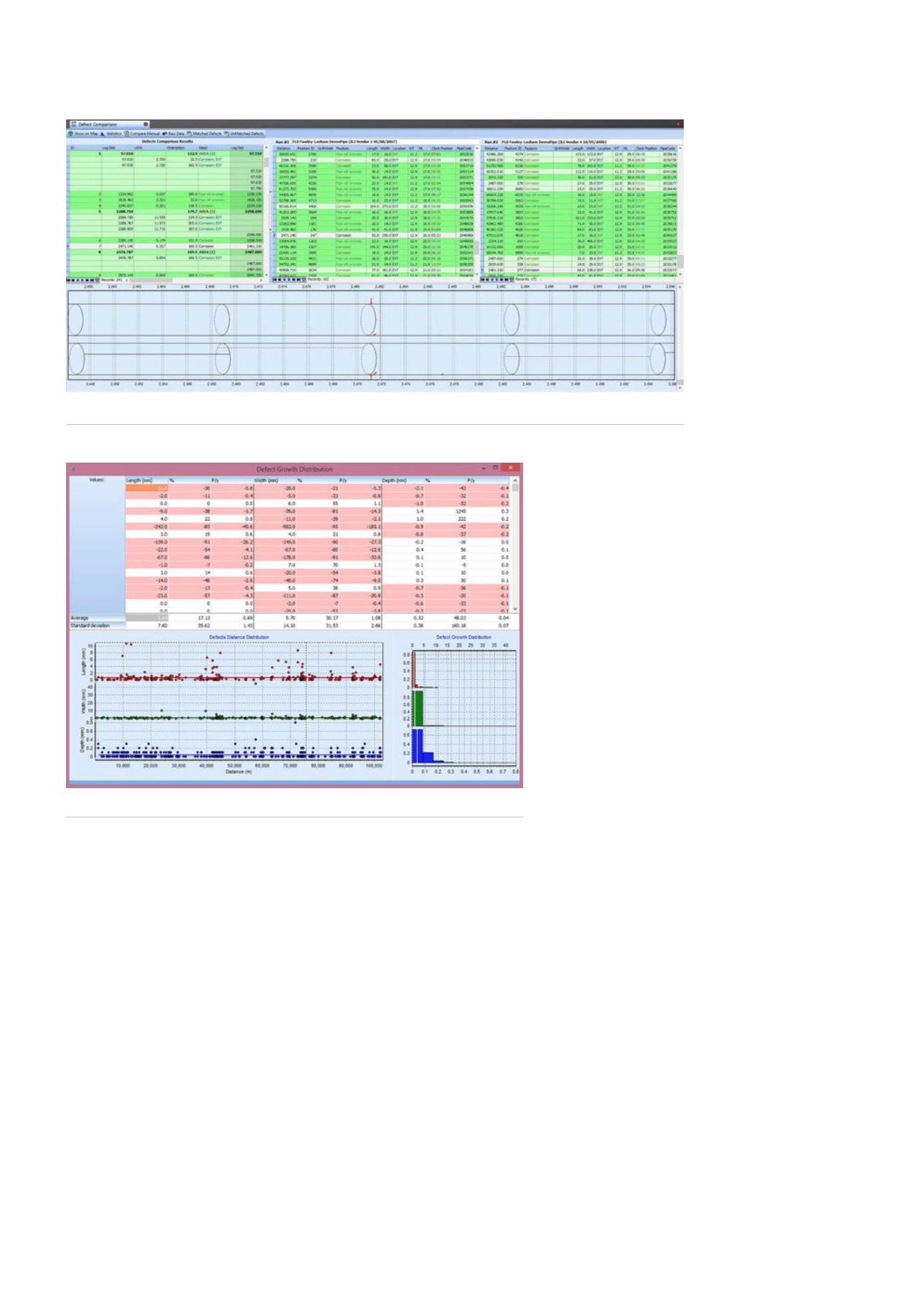

Pipelines can be inspected by ILI methods at different times

during the life of the pipeline. This means that for the same

pipeline, it is likely that multiple sets of defects are detected at

different times, possibly by different inspection companies. It

is also likely that the inspections carried out at different times

by different companies describe the same defects. It therefore

becomes very interesting for the integrity engineer to be able

to track the development of these defects over time.

Despite its apparent

simplicity, the task of

comparing pig runs is not

entirely straightforward.

When we know the

parameters of the defect

now and the parameters

five years ago, it is not

difficult to calculate

how much it may have

‘grown’. The challenge

is to be able to identify

the anomalies found in

the previous run and the

anomalies found in the

latest run are actually

describing the same

defect.

Considering that the number of anomalies

found in a pig run report can reach into the

millions for both runs, the task of ‘run comparison’

becomes close to impossible by manual analysis.

Integrity experts can still undertake this kind of

analysis with the help of readily available tools

(such as MS Excel) but the quality and results of

the work could raise some doubts.

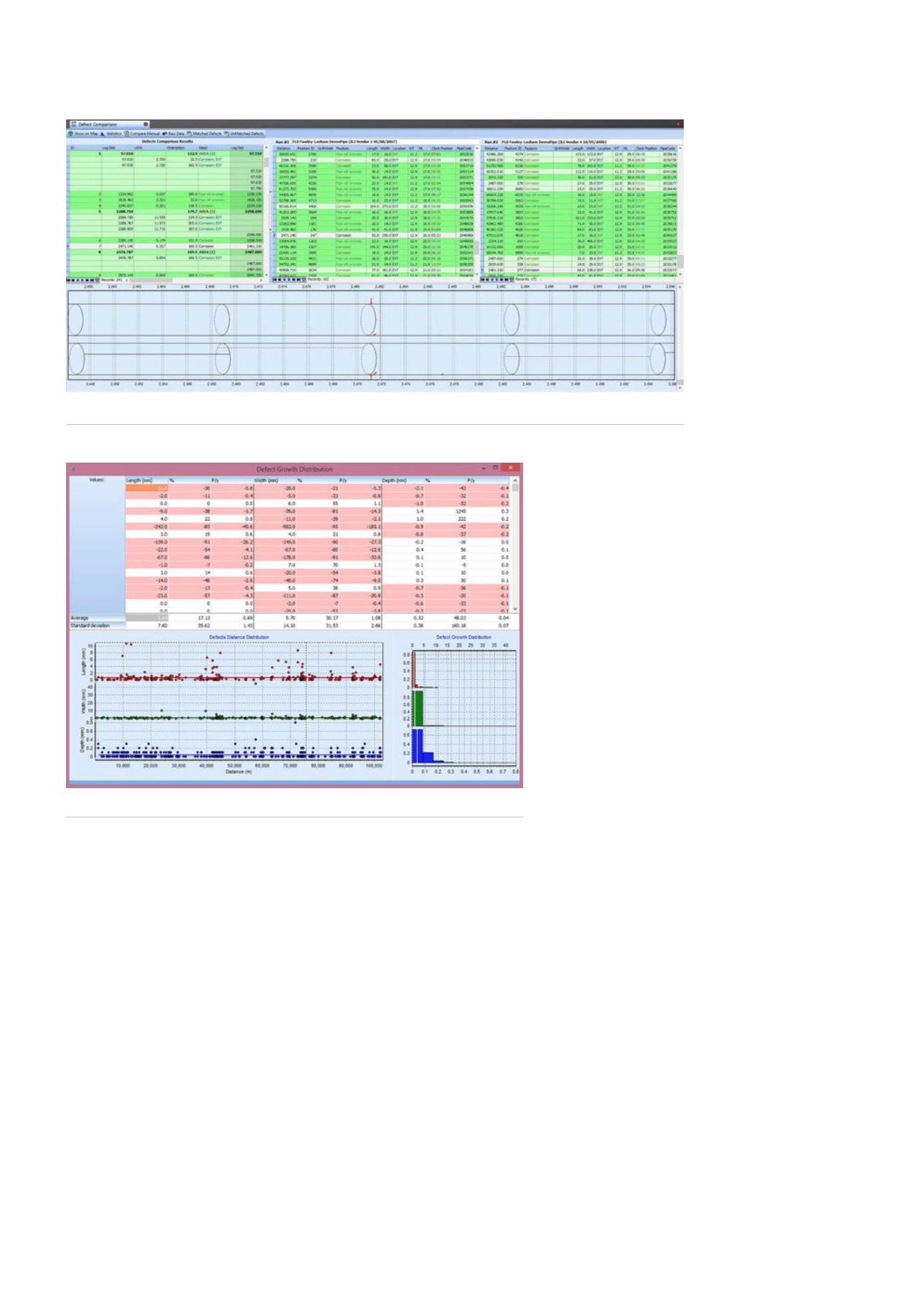

The PiMSlider ILI Expert module provides a

comprehensive set of ILI run comparison features.

What would normally be weeks of manual labour

comparing runs can now be replaced by the touch

of a button, as the software will automatically

find all the matching (and non-matching) defects

between the two pig runs.

It is then possible to automatically generate

reports, which include compared and non-

compared defects, a list of the omitted or

newly discovered joints, and the statistical

corrosion rate over the entire length of the

pipeline with the calculation of average values

and the mean distribution.

Repair planning

Whilst the PiMSlider ILI Expert module is a great tool for

analysing and documenting the results of ILIs, the next logical

step is to generate a detailed action plan, in order to address

the threats to the integrity of the pipeline based on the

results of ILI data analysis. A generated plan can include two

kinds of repair:

)

)

An urgent repair.

)

)

The need for an additional examination of the defect

(including non-destructive inspection methods – such as

NDT).

The ILI Expert module includes a complete set of tools

for assigning, storing, reporting and analysing NDT data. The

module also allows you to compare NDT data with ILI data.

Figure 2.

PiMSlider – ILI run comparison feature.

Figure 3.

Defect growth comparison screenshot.

40

World Pipelines

/

FEBRUARY 2016