cathodic protection system is critical. Has the system

been upgraded, have rectifiers been replaced or ground

beds or bonds added? Complete information greatly

assists the CIPS crew in planning and implementing close

interval survey work.

Select the CIPS type

CIPS surveys come in a variety of forms, including native

potential, depolarised, on potential and instant off, or

on-off interrupted potential that can be summarised into

two basic groups:

)

)

On potential and on-off interrupted potential surveys

are used to determine if the -850 MV criteria is being

achieved. These are the most common surveys and

are often preferred because they typically require

only a single pass over the ROW.

)

)

Native potential and depolarised surveys establish a

baseline for using the -100 MV shift criteria. This criteria

requires survey data on the potential of the structure

without CP applied and then survey data once the

current is applied so that it is possible to confirm that a

minimum shift of -100 MV has been achieved. Since the

-100 MV shift criteria requires two data sets to measure

the shift in potential they are often used only when the

-850 MV criteria is not easily achieved.

Collect the CIPS data

Once the close interval survey method is determined, CIS

crews gather data in the field with specialised equipment

by walking the length of the pipeline being surveyed. A

typical crew can effectively average about five miles per

day in moderate terrain, although a variety of factors can

affect the data collection rate.

For all CIPS surveys it is very important to identify

all of the potential current sources that might impact

the pipeline in the survey area. This would include the

pipeline’s CP systems and those CP sources that are in

the same area and could potentially have an influence

on the pipeline. There are a variety of other factors

that can impact the quality and integrity of the data

being collected. It is also quite important that the data

being collected is properly tagged to a specific location.

With today’s sub-metre (and even sub-centimetre) GPS

technology, almost all CIPS survey data is now tagged

with a specific GPS location for every data point to

facilitate data alignment.

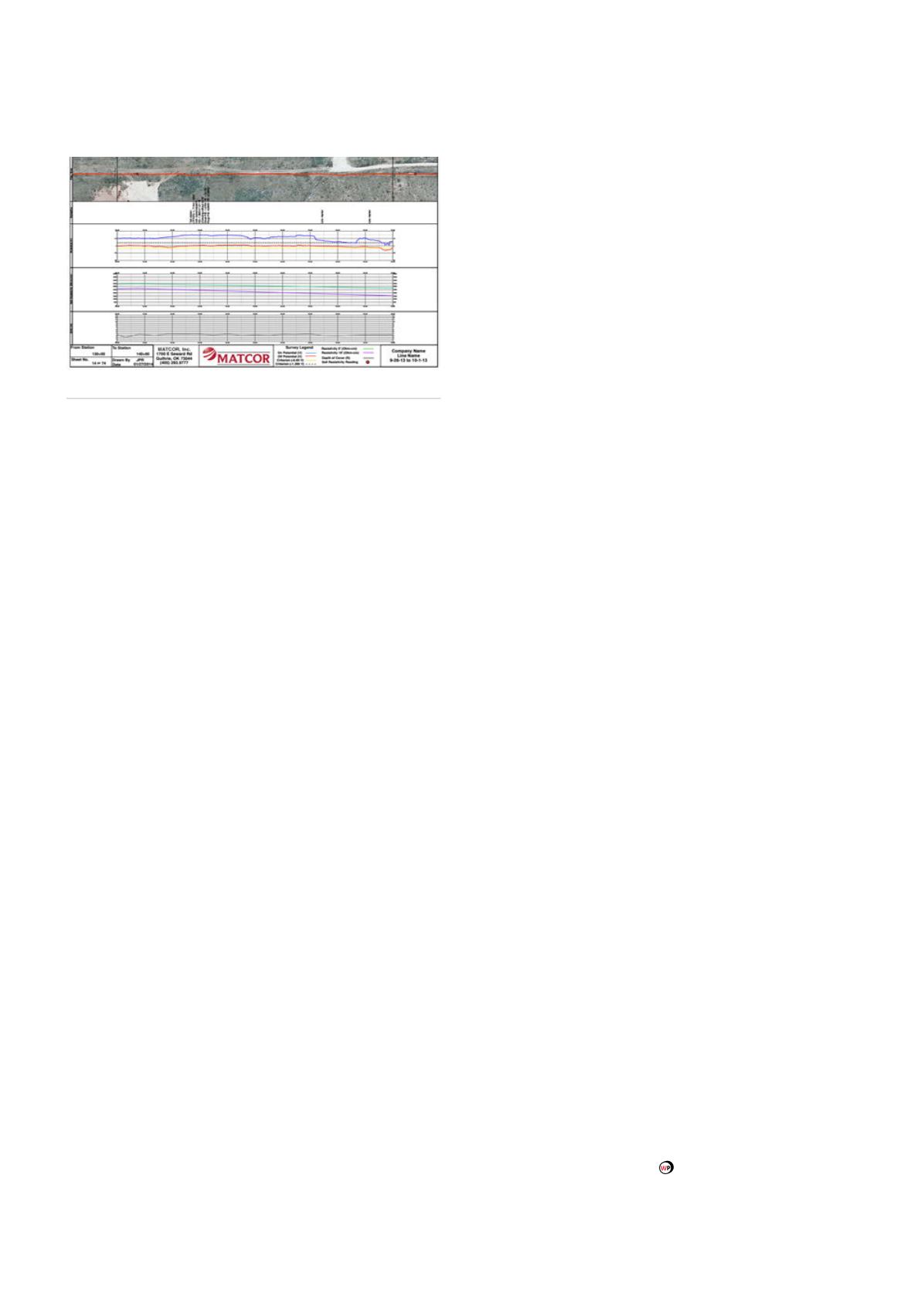

CIPS data analysis and reporting

Close interval survey data and reports typically include

regular daily or weekly field progress reports during

the survey and complete data and final reports upon

completion of the survey. Often the raw data collected

needs to be processed by a data analyst to align the

data sets and the GPS data and to eliminate spurious

readings.

Final reports typically include the raw data set, the

processed data, graphs/plots of the data, operating

details of the CP system at the time the data was

collected, ROW conditions, and any external effects on

the pipeline by other sources. Good CIS data fits right

into the pipeline GIS and compliance systems utilised

by most operators. Final CIS reports may also include an

engineering report that details the current status of the

pipeline and any potential issues that may arise from

the survey findings.

Other considerations

In some cases, CIPS surveys may be especially

challenging or conditions may make it infeasible to

collect data. This would include:

)

)

Piping that is located especially deep where potential

readings may not be accurate.

)

)

Pipelines installed in rock bores or with casings

where potential readings cannot be attained.

)

)

Areas of coating disbondment that can provide false

readings.

)

)

Frozen soils, paved roadways and very dry, rocky soils

that may not allow for accurate potential readings.

)

)

Areas under the influence of telluric earth currents or

DC transit interference.

)

)

Congested plant environments with significant plant

earthing or grounding networks.

These should be identified during the planning phase

and alternative integrity assessment methods or tools

may be required.

CIPS surveys are an effective and proven tool in the

pipeline operator’s integrity programme that can be used

to assess the effectiveness of the pipeline’s CP systems

and to identify areas of corrosion risk. When performed

on a regular basis they can be used to evaluate coating

degradation and provide information on areas requiring

additional supplemental CP.

Figure 3.

CIPS alignment sheet data presentation.

36

World Pipelines

/

FEBRUARY 2016