The CP coupons provide native and ON/OFF potentials

of the individual pipelines minimising the measurement

error. They also provide information on the current

demand of bare steel to achieve the desired protection

level in soil surrounding the pipe. The soil resistivity survey

and soil maps provide information on the type of soil and

its corrosivity.

Predicting the corrosion and CP polarisation behaviour

of the pipe is accomplished by combining the coupon

data with soil information. The RMUs of the rectifiers

monitor the total current output (current demand) of each

individual pipeline in a specific region.

The inline cathodic current mapping inspection tool

(smart pig) measures the voltage drop caused by the axial

CP current that flows in the pipeline wall. The data set

provides an appreciation of the coating condition, which is

used to localise and quantify the current exchanged with

other structures of influence (e.g. bonding between pipes,

shorts to ground).

The field data, pipeline properties and the

characteristics of the CP system are consolidated in

a computational model that enables calculating true

protection levels of the individual pipelines.

Connecting the dots

Advances in electronics and portable power capacity

over the past 20 years have now enabled unprecedented

access to immense volumes of information that can be

transmitted almost instantaneously from remote locations

very economically. The ‘big data’ needs to be stored,

visualised and, most importantly, analysed and evaluated

in a practical and cost-efficient manner. Moreover, the

abovementioned field data provides valuable information

on individual parameters, but a correlation must be made

between the data, which is not an easy task for such a

complex system.

For example, the ON potential is determined by

the coating resistance, soil resistivity and CP current

distribution. The axial current is a result of the CP current

distribution on the pipe, but does not provide information

on whether or not the minimum pipe-to-soil potential of

-850 mV or 100 mV polarisation shift is achieved at the

pipe surface of a complex multiple pipeline corridor. An

intelligent analysis tool is required to automatically treat

the large set of data and unambiguously find correlations

between the pipeline and CP parameters to objectively

draw the correct conclusions.

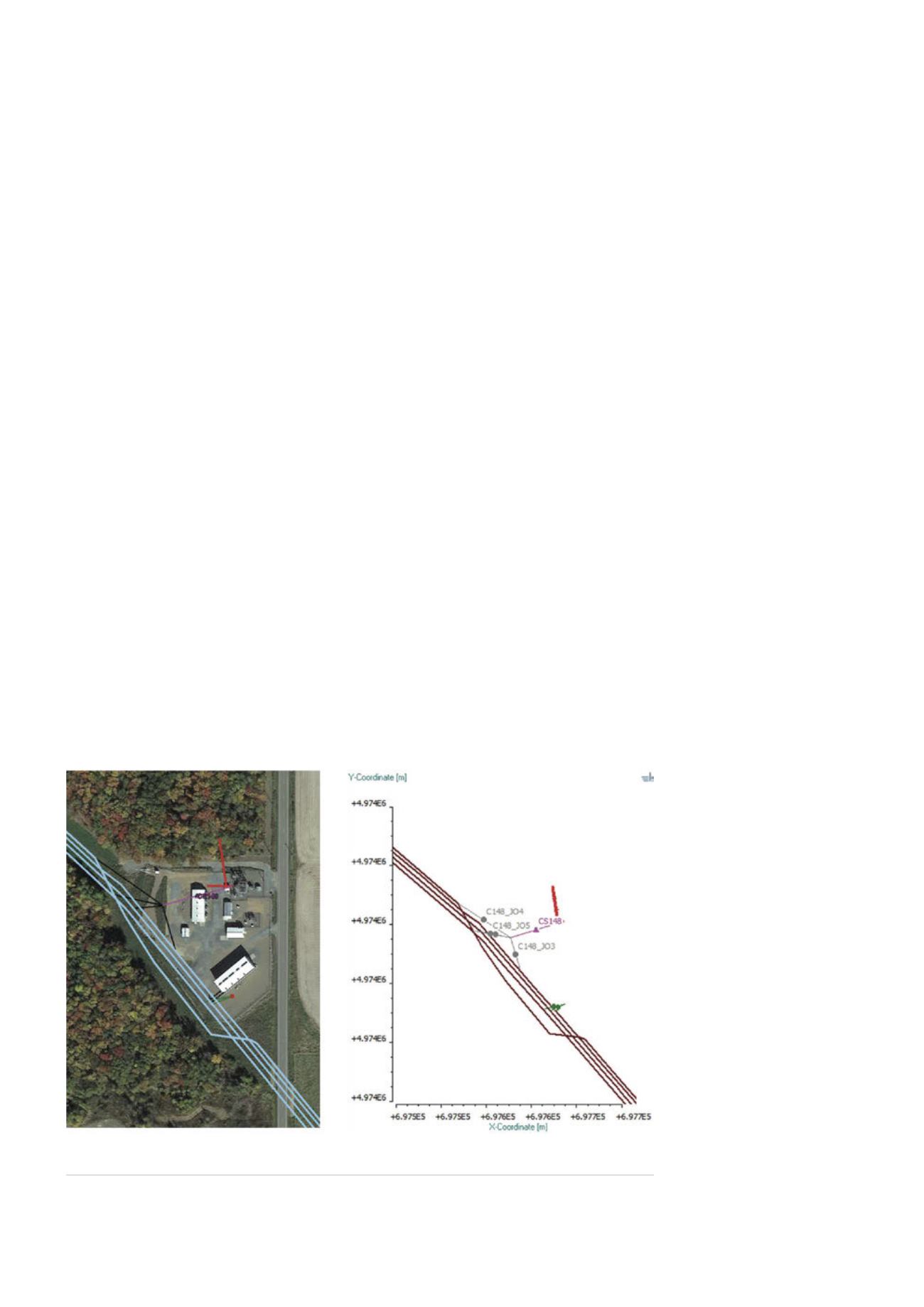

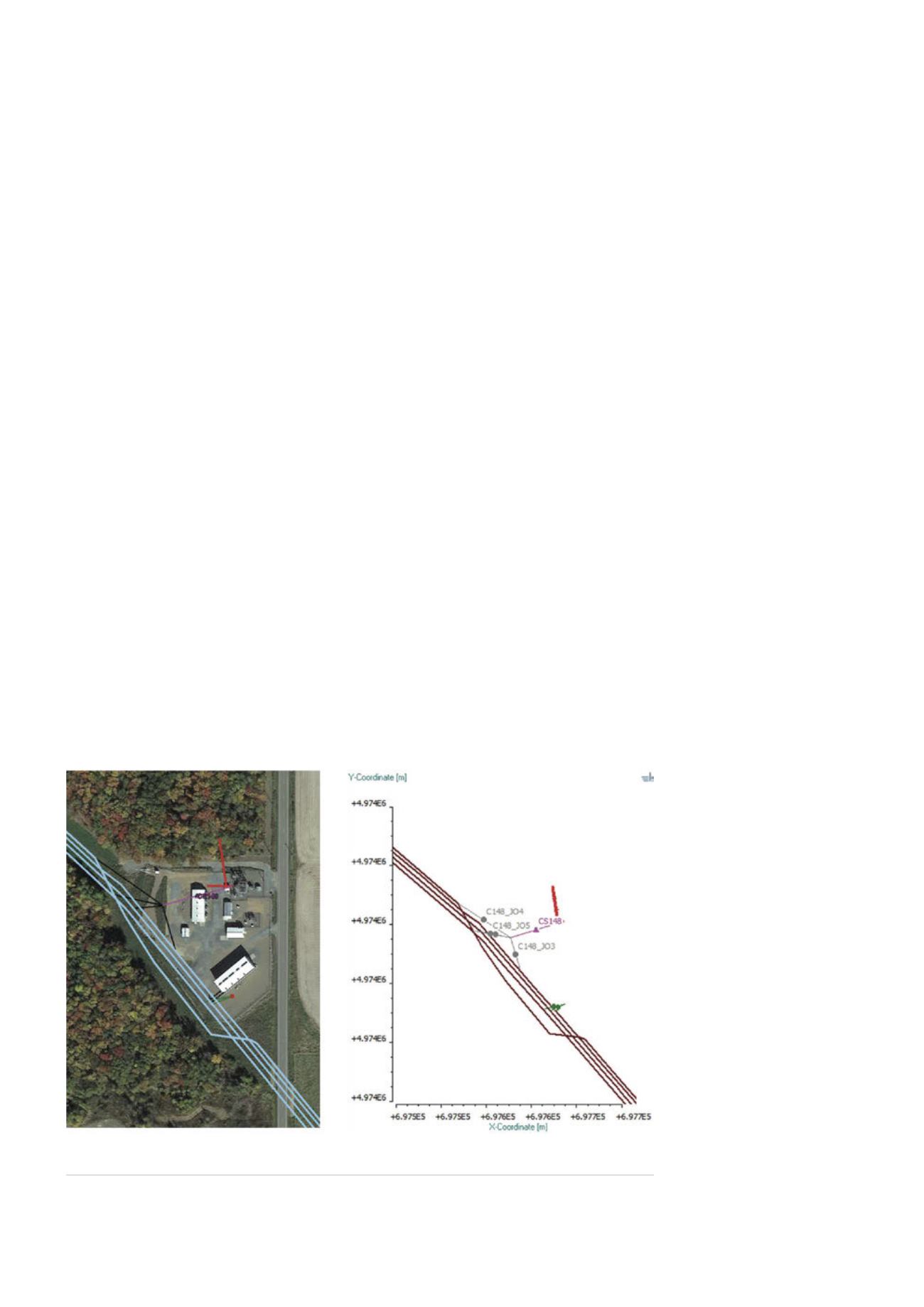

The Elsyca CatPro software is a BEM/FEM based

computational tool that simulates the CP and corrosion

behaviour of e.g. multiple pipeline corridors. The software

connects the dots by integrating all the field data and

system properties in a 3D physical model of the pipelines

and CP components. All relevant parameters such as

the exact pipeline routing based on GPS co-ordinates,

location/geometry of anode beds, cabling to rectifiers,

bonds between pipelines, drains to groundings etc. are

assimilated. Such a model calculates the CP current

distribution in the soil, and determines the polarisation

level as a function of the coating resistance of the entire

pipeline corridor.

Firstly, the coating resistance is estimated based on the

coating type, pipeline vintage and local soil resistivity. The

monitored current output of the rectifiers is applied in the

model and an initial simulation is obtained that provides

results on:

)

)

Pipe-to-soil ON potential at grade level or at any depth.

)

)

IR-free potential at pipeline surface.

)

)

Current density leaving/

entering the pipeline.

)

)

Axial current through the

pipe wall.

)

)

Rectifier voltage and

current output.

)

)

Current through bonds

and drains.

Parameters such as

ON potential and current

flow (axial current through

the pipeline wall, rectifier

output and current exchange

through bonds and drains)

are used to calibrate

the model for the as-is

condition. The simulation

results are again compared

with the measured field

data and if a discrepancy is

Figure 3.

3D computational model of pipeline corridor with CP system (red line) and electrical

shortings (green line).

28

World Pipelines

/

FEBRUARY 2016