Results and discussion

Weathering

Because polyester is the main binder system in the top coat,

various UV protection formulation adjustments were made

to improve Sol-Gard reactivity and ensure it meets the

coating application and pipeline installation requirements.

A two year weathering test in Florida (USA) was completed

to study the changes when Sol-Gard coating was exposed

to the local weather conditions (Figure 1). To complete this

test, coating coupons were sent to a testing lab where gloss

(60˚) and colour were studied every three months for the first

12 months. This testing was then repeated every six months

afterwards for up to two years.

The results showed no gloss change for the first 12 months.

In fact, initial gloss was approximately 85 and results indicated

that the gloss rate was still over 80 after the 12 months had

passed. After two years of exposure, the gloss level dropped

to over 40 while the overall coating integrity remained strong.

A minor visible colour change did occur as indicated by the

colour change index Delta E that was still well below 1.0.

Application trial

The FBE and polyester dual powder systems were applied at

a customer’s coating line without any issues. The pipe was

Table 1. Dual powder system test results

Test

Acceptance

criteria

Results

Cathodic

disbondment

(24 hr/3.5V/65˚C)

≤

6.5 mm

3.0 mm 3.2 mm Pass

Adhesion

(24 hr/75˚C)

1 - 3 rating

1

1

Pass

2.5˚ flexibility at

-30˚C

No cracking or tear Pass Pass

Pass

3.0J impact at -30˚C No holidays

Pass Pass

Pass

Interface porosity 1 - 4 rating

2

2

Pass

Cross-section

porosity

1 - 4 rating

2

1

Pass

DCS cure

Δ

Tg <5˚C

0.4˚C 0.2˚C Pass

Surface

contamination

≤

35%

10% 15% Pass

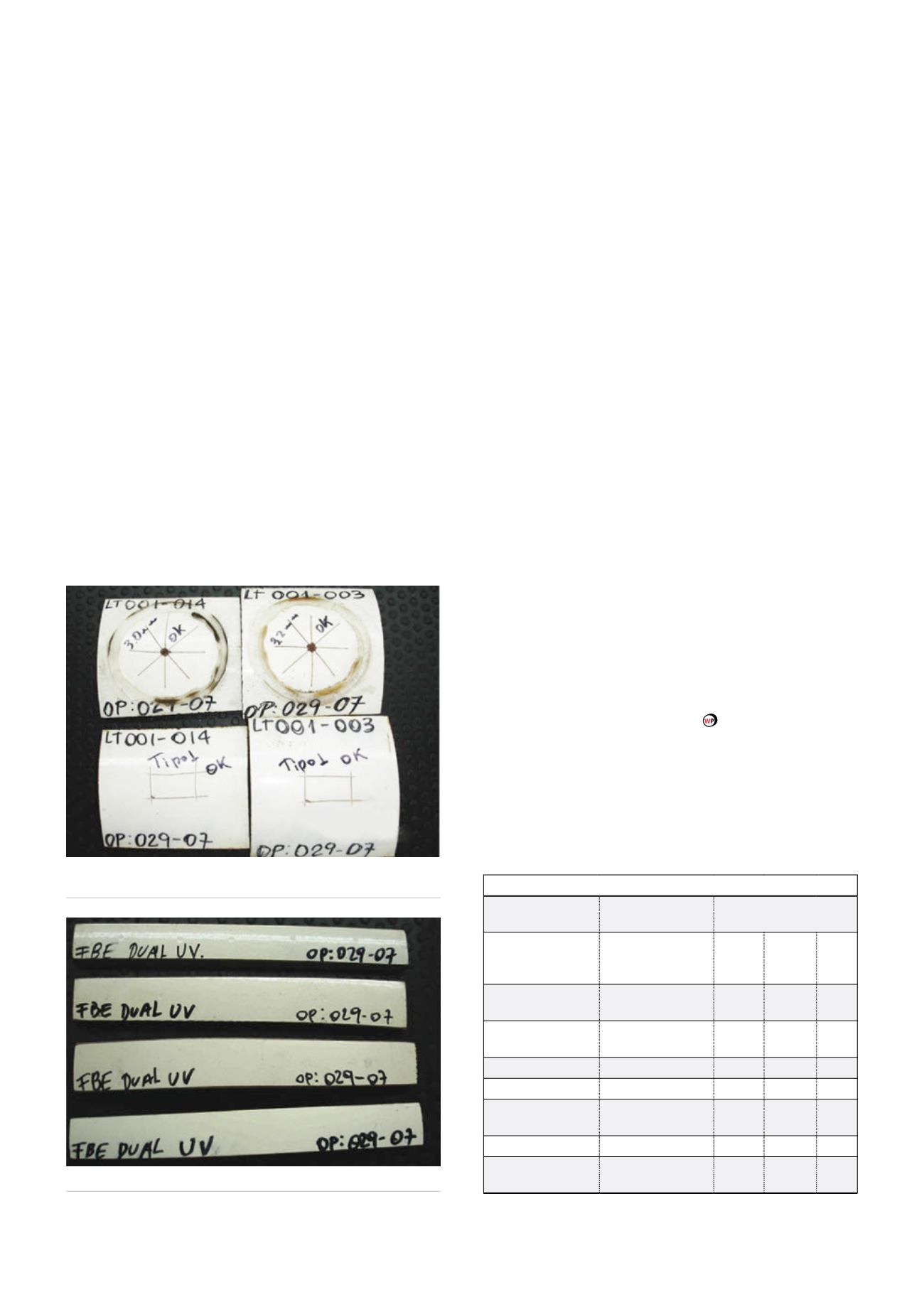

Figure 2.

Water soak and cathodic disbondment of the dual

powder system.

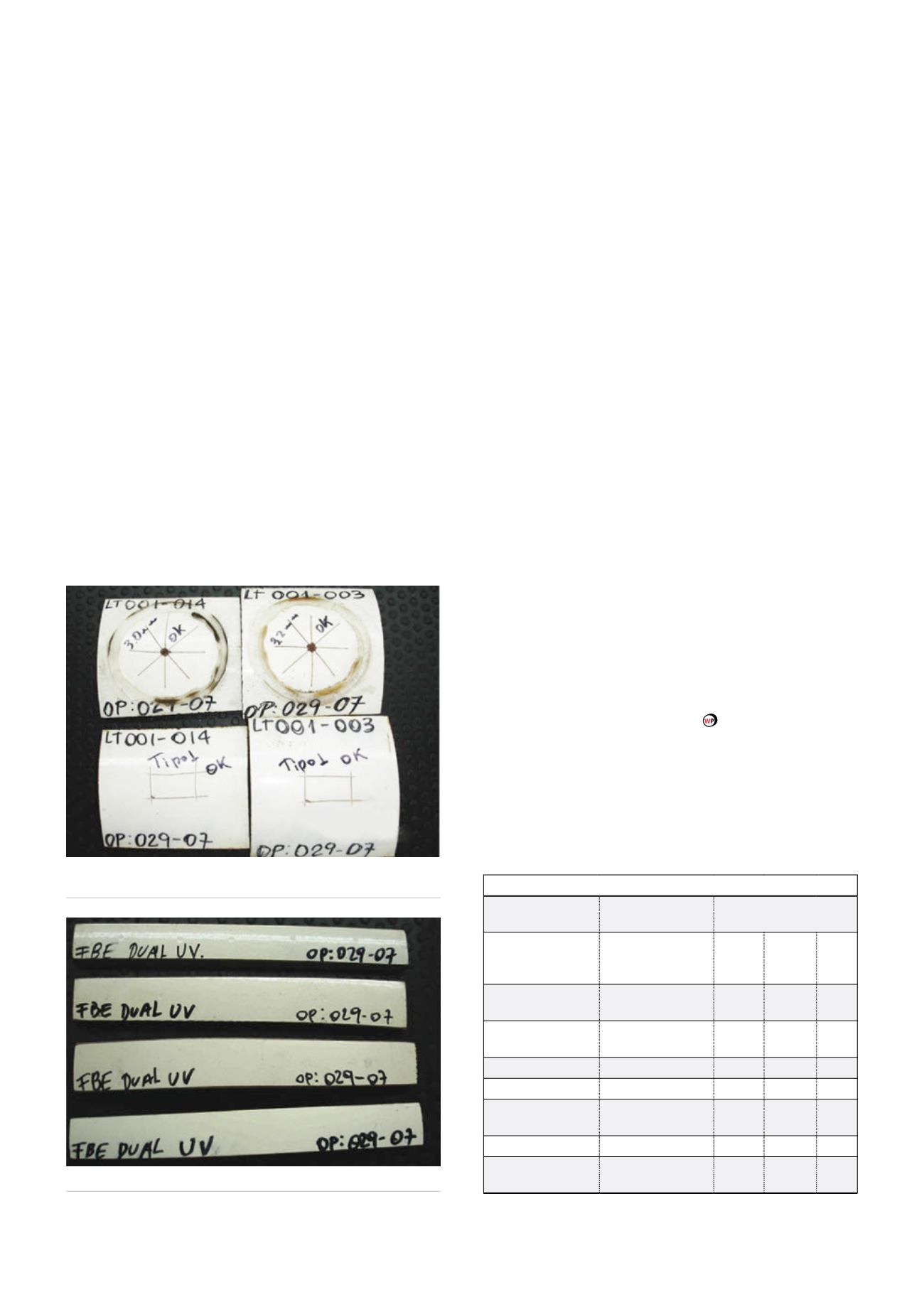

Figure 3.

Impact and flexibility of the dual powder system.

preheated to 239˚C (463˚F). The first layer applied was FBE

corrosion coating at 355.6

±

50.8

μ

(14

±

2 mm), followed by

Sol-Gard powder coating at 76.2 - 101.6

μ

(3 - 4 mm). With

a CSA gel time of 28

±

6 secs for the top coat, the dual

powder system was fully cured in 90 secs (quench time).

DSC cure data indicated the Delta Tg was less than 0.5˚C,

which was well below the requirement of less than 5˚C

(Table 1).

Figure 2 shows the 24 hr/75˚C water soak adhesion and

24 hr/65˚C/3.5V cathodic disbondment test results for the

trialled ring samples. Water soak adhesion for both tested

coupons were rated as 1 after the 24 hr/75˚C test and

the cathodic disbondment results were 3 mm and 3.2 mm,

which are within the specification of 6.5 mm.

The coupons were also tested for impact and flexibility

requirements. The test’s outcome on the dual powder

system showed a passing rate of 3.0J on impact and 2.5˚/

PDL flexibility requirement, both at -30˚C.

Impact results are depicted in the top two coupons

of Figure 3 and flexibility findings are found in the bottom

two coupons. Coating porosity, surface contamination

and degree of cure were also evaluated with satisfactory

results. Table 1 summarises all test results.

Summary

The key to successful UV protection for coated line pipe

is a combination of an FBE single layer or dual layer FBE

system followed by a polyester powder top coat. Dual

powder systems using Sol-Gard are generally very easily

applied in the current pipe coating line without any issues

and produce excellent interlayer adhesion. Testing has

confirmed that Sol-Gard meets the desired flexibility and

field bend requirements and is recommended for use

whenever UV radiation is a concern.

Bibliography

1.

KEHR A.J., Fusion Bonded Epoxy (FBE): A Foundation for Pipeline Corrosion

Protection, NACE International, 2003.

2.

CENTINER, M., Singh, P., and ABES, J., Stockpiled FBE - Coated Line Pipe Can

Be Subject to UV Degradatio,. 2001.

24

World Pipelines

/

FEBRUARY 2016