CP. A more holistic and sophisticated approach is necessary

to achieve efficient CP management of a multiple pipeline

corridor.

Challenging unbalanced CP systems

CP of pipelines has demonstrated its value since the late

1940s. The effectiveness of the corrosion protection method

is relatively well understood and straightforward for simple

configurations, such as single pipelines or storage tanks.

Newer grades of steel with less carbon and development

of higher performance coating materials have generally

improved the overall quality of the infrastructure, resulting

in better resistance to external corrosion. However, the risk

for external corrosion can increase when a pipeline network

expansion is planned within an existing corridor. Each time

a new pipeline is introduced within the corridor, significant

changes in the electrical properties of the new network

can occur and a shift in CP current distribution between

lines is not unusual. This can create imbalance within the CP

system, where back feeding of current can occur at rectifiers.

Identifying the critical areas that cause the instability of the

CP system is sometimes difficult to achieve with conventional

CP evaluation techniques. The information collected on the

pipelines are usually not discrete measurements that lead to

inconsistent or unreliable results because:

)

Measured ON potentials are rather mixed values.

)

Cathodic/anodic current exchange may not stabilise

within typical OFF cycle due to capacitive differences

between the coatings.

)

Measurements may be influenced by

significant IR-drop because of residual

currents flowing between the pipelines.

Additionally, high-voltage power lines

may enter the ROW and cause alternating

current (AC) induced corrosion. It has been

established that control of AC corrosion

must be done in conjunction with

appropriate CP settings.

Enbridge operates the world’s longest

and most complex crude oil and liquid

hydrocarbon transportation system having

close to 25 000 km (15 500 miles) of pipeline

throughout North America. Areas of the

mainline corridor contain up to seven

parallel pipelines within the same ROW. The

common practice with facility expansion

has been to connect new pipelines into a

CP system common with the existing lines.

Upgrades are consequently made, which

include installation of auxiliary systems to

satisfy the increased current demand.

Presently, the ROW includes an

assortment of pipeline vintages

(1949 - 2008) with various diameters

(12 - 48 in.) and coating types (coal tar,

PE-taped, FBE and HPCC/HPPC), which has

consequently resulted in unbalanced CP levels. Variations

in soil properties along the corridor, and the occurrence of

inadvertent electrical shorting with grounding at motorised

valve stations, have contributed to the complexity of the

problem.

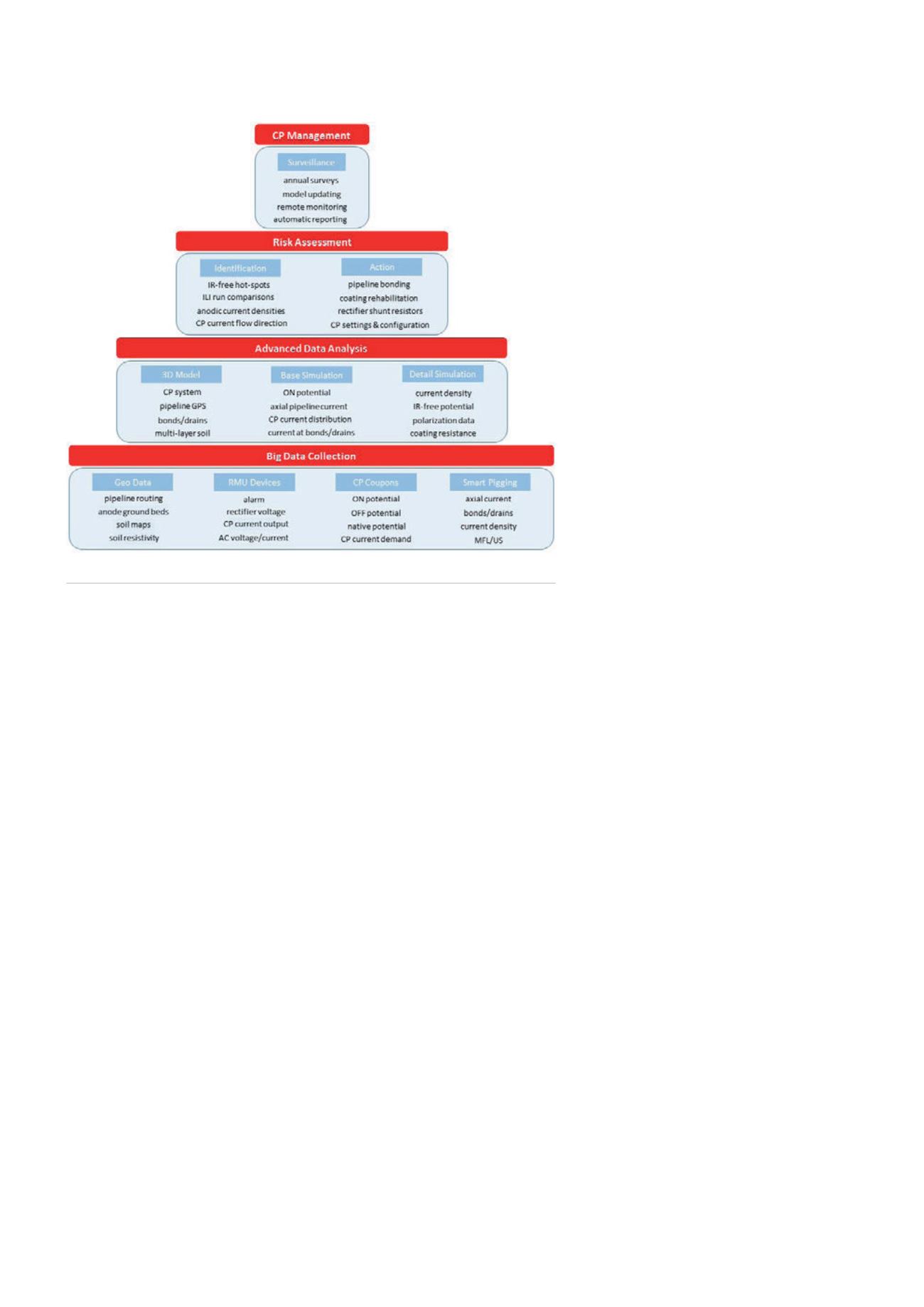

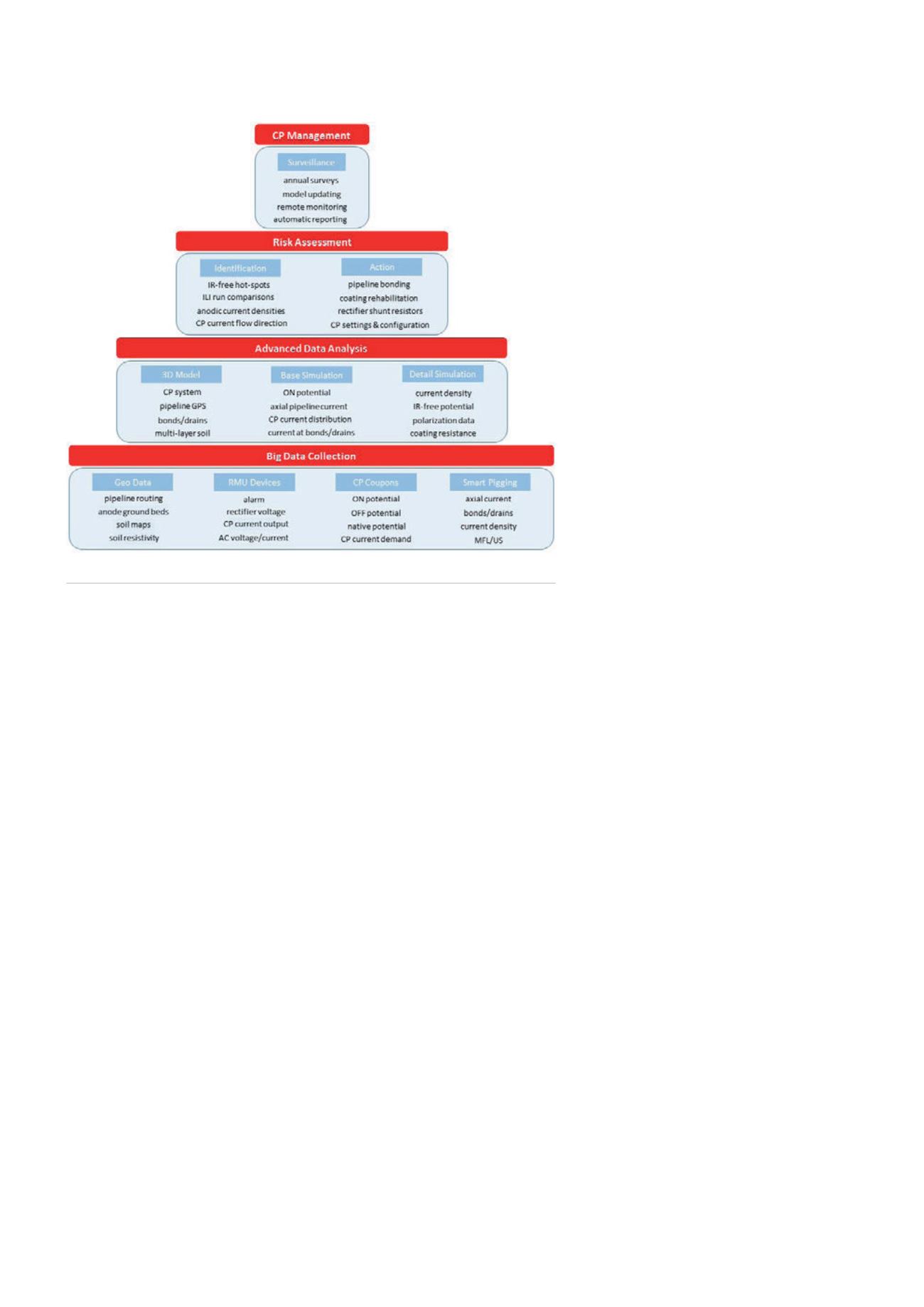

The holistic approach

Consecutive inline inspection runs (MFL and US) have

detected features with corrosion growth on both the

legacy and expansion project pipelines within a mutual

corridor. Consequently, Enbridge has adopted a more

holistic approach for identifying the root cause of the

corrosion attack and strategically implementing counter

measures for stabilising the CP system.

Proper CP control requires knowledge on the coating

condition, the soil properties and the current distribution

along the pipeline, and the polarisation behaviour of the

steel surface at coating defects. Conventional CP surveys

do not reliably provide this information for such complex

pipeline systems. Therefore, the following state-of-the-art

technologies were applied:

)

CP coupons with stationary reference cells and data

loggers/RMUs.

)

Soil resistivity surveys and soil maps.

)

Remote monitoring of rectifier outputs.

)

Inline cathodic current mapping inspection.

)

Advanced computational modelling.

Figure 2.

Holistic approach for CP managing of multiple pipeline corridors.

26

World Pipelines

/

FEBRUARY 2016