potential shift changes the environment around the metal

and inhibits the corrosion reaction as the steel structure

is

polarised. With sufficient polarisation, the

corrosion rate

for the metallic pipeline is reduced to virtually zero and

the corrosion risk is eliminated.

Though the vast majority of pipelines are carbon

steel and the technology is applicable for other metallic

pipelines, for the purpose of this article, metallic and

carbon steel are used interchangeably. Since pipeline

operators utilise coatings and CP to prevent their carbon

steel pipeline from corrosion damage that can adversely

affect the integrity of their assets, they should be very

interested in assessing the condition of the coating and

the effectiveness of the CP system. One of the most

effective tools to assess the effectiveness of a pipeline’s

CP system and the condition of the pipeline’s coating

system is the CIPS survey.

What does a CIPS survey do?

The goal of any CIPS survey is to measure the electrical

potential of the steel pipeline along the length of the

pipeline area being surveyed. As noted earlier, the goal of

CP is to polarise those exposed areas along the pipeline

that are not fully isolated from the environment by the

coating system. If the coating system for a 10 km long,

12 in. dia. pipeline were 99% effective and only had 1% of

holidays, there would be almost 96 m

2

of exposed steel

along the length of pipeline. Each of these coating defects

or holidays along the pipeline are potential corrosion

sites unless the CP system is properly polarising the

pipeline along its entire length.

While there are a variety of accepted criteria for what

constitutes proper polarisation, the two most widely

accepted are those detailed in NACE specifications –

the criteria descriptions are simplified and apply to the

majority of buried and submerged pipelines in typical

ambient temperature environments, where the criteria may

need to be adjusted for elevated operating temperatures

and especially corrosive chemical environments.

The first is the -850 MV polarised potential criteria.

NACE deems any pipeline that has a negative polarised

potential of -850 MV to meet the criteria for effective

CP. The second is to demonstrate that there is at least a

-100 MV shift of the polarised structure from its native

or depolarised potential. The data collected in the

CIPS survey allows the pipeline operator to assess the

polarised potential of the pipeline to ensure that it meets

criteria and that the CP system is working effectively in

conjunction with the coating system to prevent corrosion.

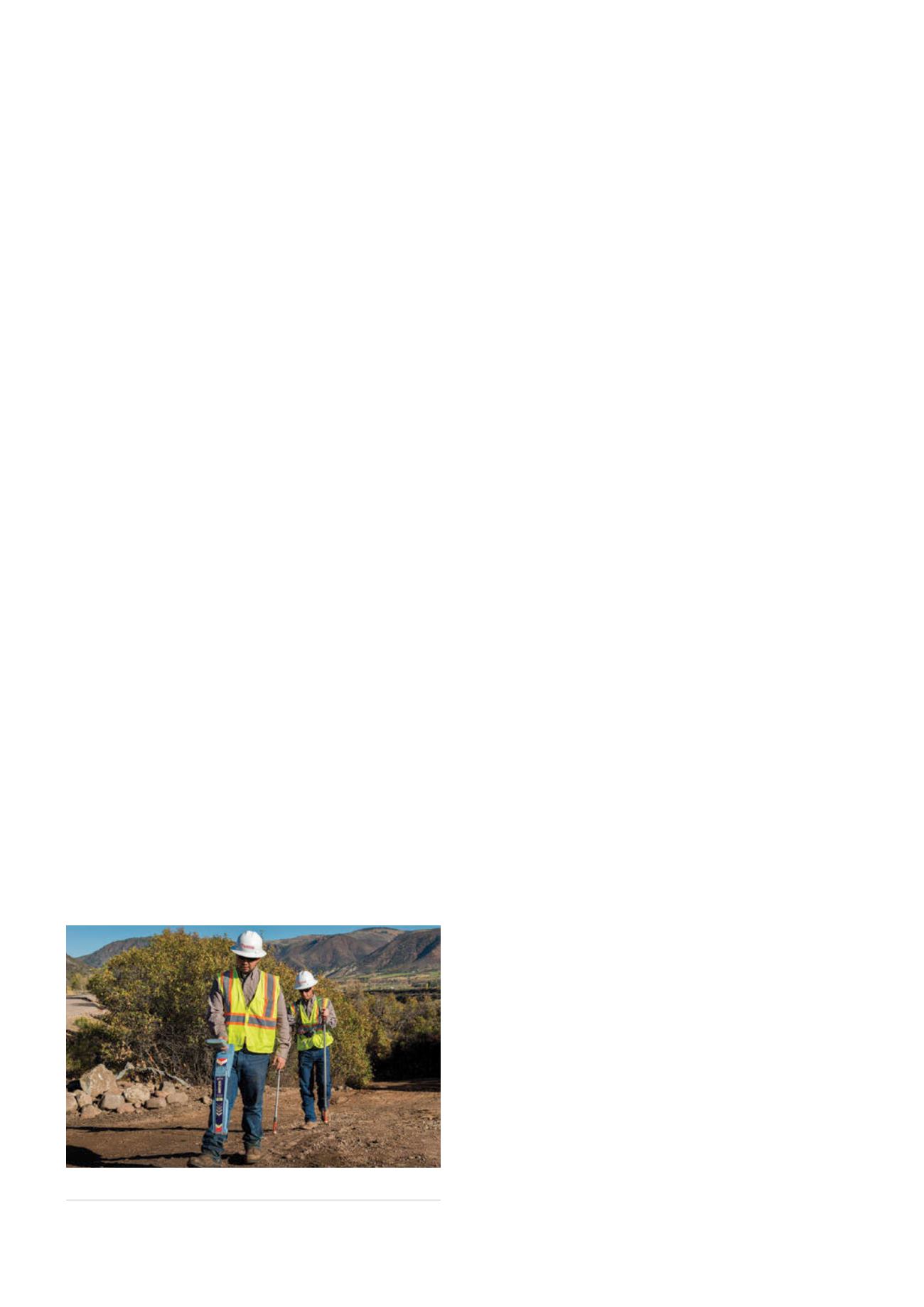

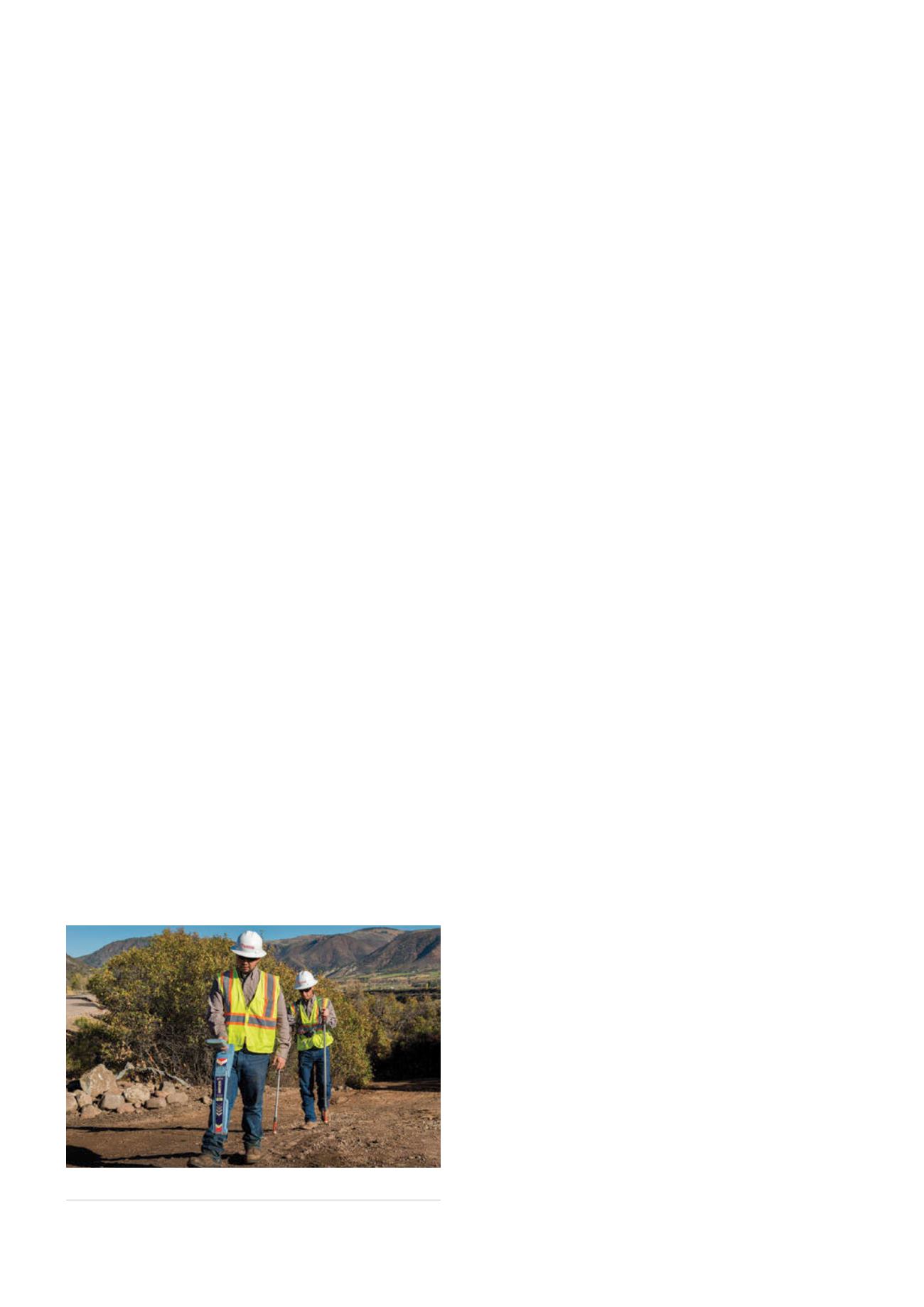

The CIPS survey can be conducted on buried or

submerged pipelines. At regular intervals along the

pipeline – typically every 2.5 ft (76 cm) – measurements

are taken of the potential or voltage difference between

the pipeline, and a reference electrode in contact with

the soil or water. That is a technician with the two poles.

Every step along the ROW one of the poles makes contact

with the ground, and the technician pushes a button that

submits data collected by the data logger in a backpack.

The data collected during a close interval survey can be

used to establish a baseline for CP on a new pipeline,

or assess the performance and operation of existing

underground pipeline CP systems. CIPS can also identify

areas with insufficient CP and may detect large coating

defects or holidays, however small defects may not be

detected.

Keys to a successful CIPS survey

Selecting a qualified survey crew

Whether the CIPS survey is being performed by the

pipeline operator’s personnel or by a supplier that

specialises in these surveys, the qualifications and

experience of the survey crew are critical to collecting

accurate data. When contracting the CIPS survey work

key considerations should include: safety record, makeup

of crew, whether crew members are full time employees

or subcontractors, the type of equipment they have,

engineering and IT support for data analysis and reporting,

and turnaround time for reporting.

Many operators have started to specify that at

least the crew leader must have NACE certification,

that the crews must be full time employees and not

subcontractors, and that a NACE CP or corrosion

specialist must review and stamp the final report. One

additional note on contracting CIPS surveys – some

survey companies compensate the field crew based on

miles per day. This model has led to data being collected

quickly, but often not correctly as the crew rushes down

the ROW. Many operators prefer to pay a fixed crew day

rate to avoid the danger of pay-per-mile incentives.

Advanced planning

Before any survey, it is important to properly plan.

Typical information required in advance of starting a CIPS

survey includes historical survey data, rectifier output

information, maps and alignment sheets detailing the

pipeline, surrounding terrain and structures. Also helpful

is information about any remediation done in the area,

such as construction activity, additional pipelines or

new power lines. Noting any changes or upgrades to the

Figure 2.

CIPS crew gathers potential data along pipeline ROW.

34

World Pipelines

/

FEBRUARY 2016