identified further adjustments and refinement to the model

is made.

Secondly, smaller pipeline sections are defined and

the coating resistance of each section of the individual

pipelines is adjusted until the simulation results are aligned

with accurately measured field data. Persistent deviations

are often explained by incorrect or missing field data and

undocumented changes to the system. Typical examples

are accidental drains, failed equipment or non-reported

bonds or electrical shorting. Once clarified a baseline

model with the correct distribution of the CP current is

obtained. Multiple iterations and a continual integration

of field data are required to obtain a realistic model of

such a complex system. Some special algorithms are under

development to automate this process.

Finally, the model allows a quantitative analysis of the

CP effectiveness, where the OFF potential and coupon

current demand are used to define the polarisation curve

of steel in the local soil. Since the CP current distribution

has been calculated for each pipeline section in the

previous step, the amount of current entering the pipe

through the soil is now known. Through the polarisation

curve, the current can then be converted to true or IR-free

potential of the pipeline. Polarisation levels can be further

refined by characterising the size and amount of coating

defects. Segments that do not receive sufficient CP current

or experience an anodic stress due to the other pipelines

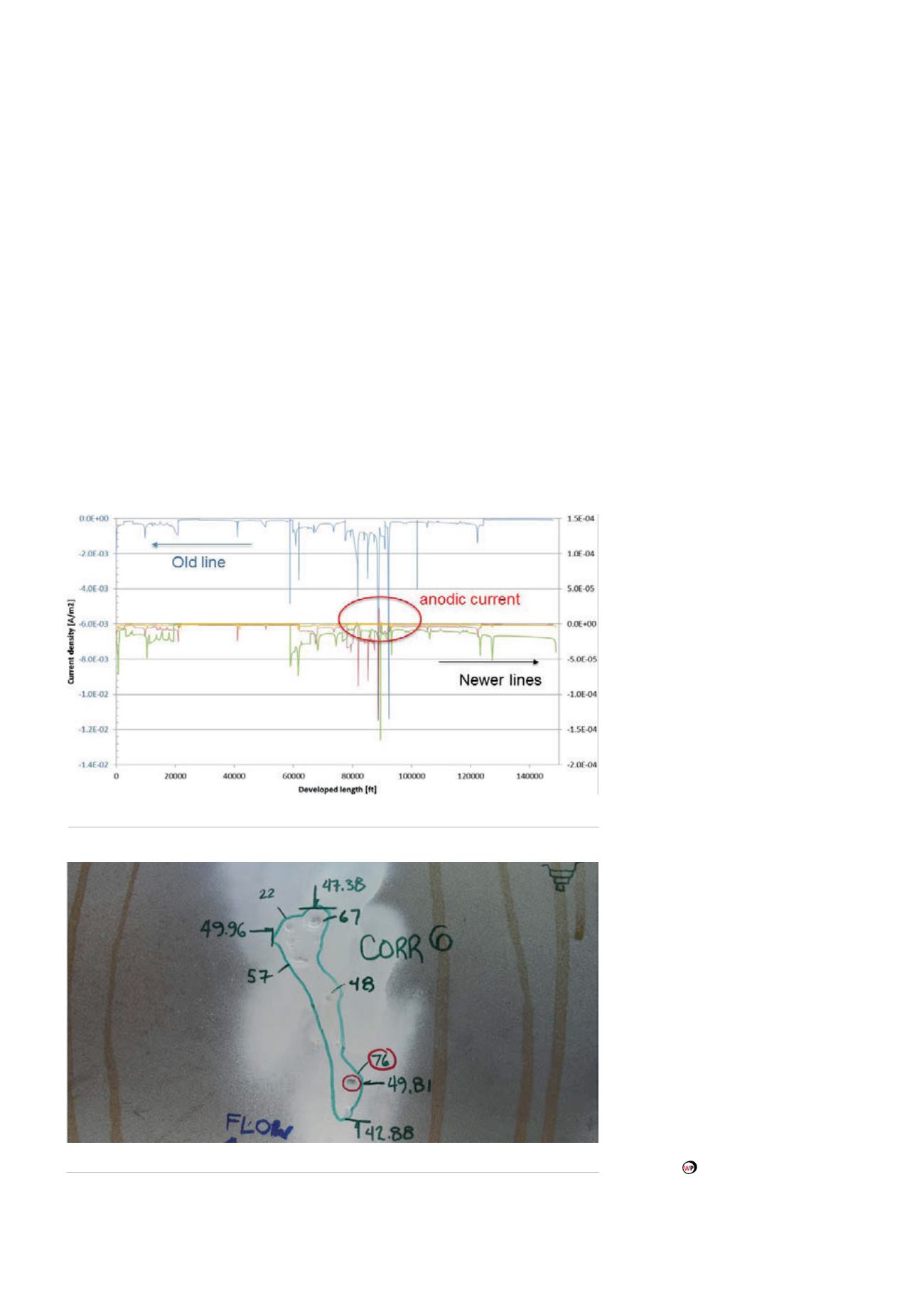

present in the same ROW become apparent. As an example,

Figure 4 shows an area with a transition of soil type near

a waterway that resulted in some sections on two recent

pipelines tending to have (slightly) positive or anodic

current density.

Treat the disease, not the symptoms

Once the model is in place, strategic counter measure

scenarios can be reviewed at the design stages of

expansion projects for a relatively low cost. Ad hoc actions

in the field such as adding anode beds to bring potentials

to more negative values can sometimes worsen the

situation in unexpected remote locations. Equipotential

bonds should be installed at the

appropriate locations to avoid CP

currents from flowing in undesirable

directions.

Alternatively, the model has

revealed that it is crucial for shunt

resistors to be installed for each

rectifier negative cable connecting

the individual pipelines. The value of

the resistor is calculated by dividing

the average IR-free potential by the

axial current occurring in the sections

with the most electropositive

potentials. The resistor should be

installed in the line with the most

electronegative potentials. Through

iteration the resistor value for each

line is optimised.

Proposed solutions are verified

up-front by introducing them in the

model and calculating their global

impact on the CP performance. As

such, logical control and optimisation

of the CP system becomes feasible,

eliminating costly excavations and

substantially reducing the risk of

failure.

Continuous surveillance of the

CP status becomes cost-effective

by keeping the model apprised with

incoming remote monitoring data

and field measurements. Changes in

the protection behaviour of each

individual pipeline are visualised in

a geographic information system

and new simulations are easily

updated.

Figure 4.

Simulated current densities indicating areas with anodic behaviour.

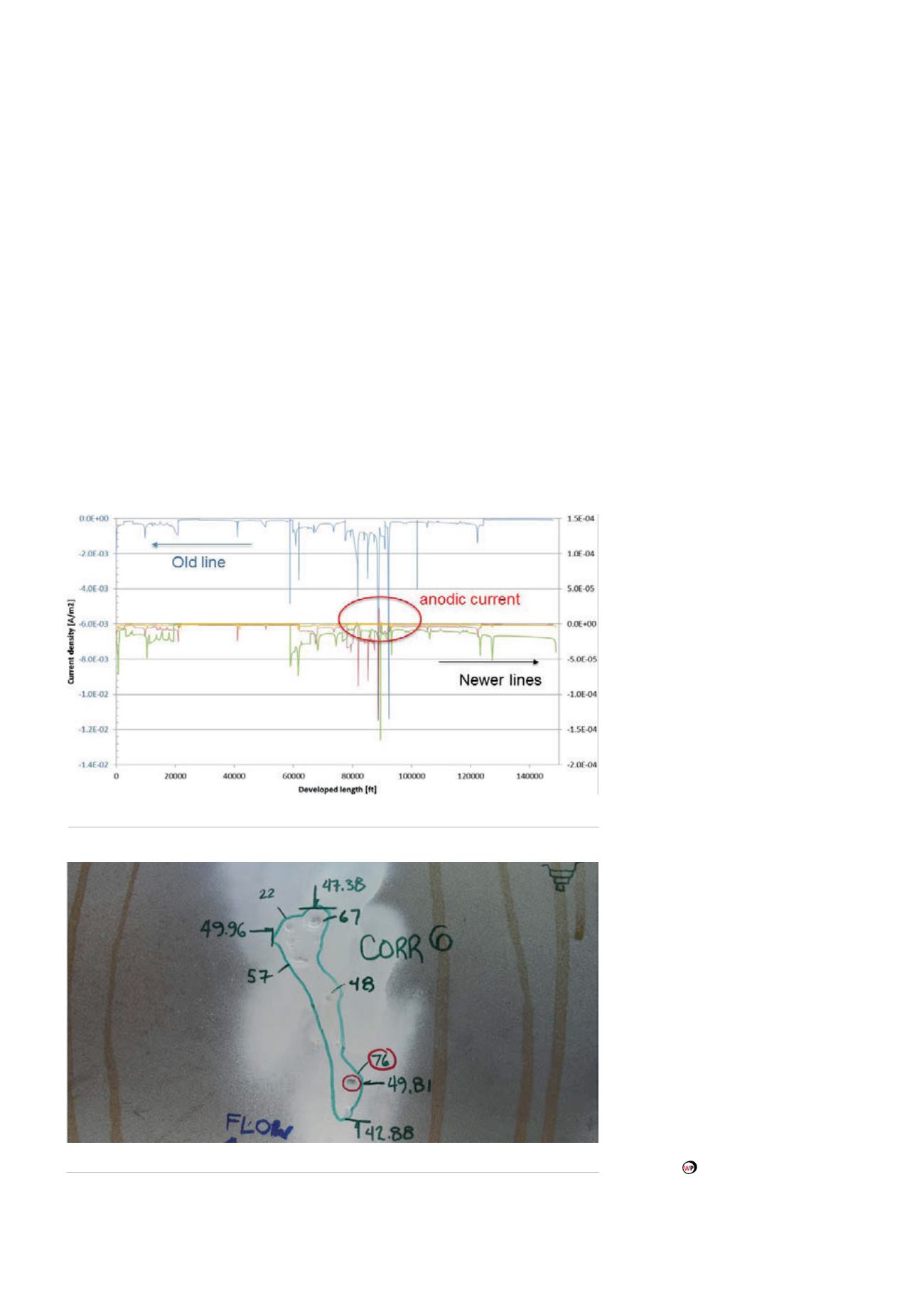

Figure 5.

Example of corrosion attack caused by interference between pipelines.

30

World Pipelines

/

FEBRUARY 2016