of loose powdery residue on the coating’s surface is known

as chalking. The extent of chalking depends on the extent

of the direct exposure to UV radiation, the intensity and the

duration of the UV radiation, and the availability of water on

the coating surface.

1

The two main FBE properties affected by chalking are

thickness and flexibility. When chalking occurs, the coating

itself is actually degrading, which leads to a loss in overall

coating thickness over time. Historical observation suggests

that this thickness loss typically begins within 9 - 18 months

after chalking commences.

2

The typical rate of thickness loss

due to chalking is 10 - 40 mm/y.

Sections of pipe stockpiled in Alberta (Canada) and North

Dakota (USA) were analysed for thickness and flexibility after

16 - 21 months of exposure. Results showed a 25 - 50 mm

thickness loss and a significant decrease in flexibility that

failed the 2.5˚ pipe diameter flexibility requirements outlined

in CSA Z245.20-98. No significant differences were observed

regarding cathodic disbondment, adhesion or impact

properties. From this study it was determined that FBE

coatings should be protected in some manner if exposure to

UV radiation for periods over one year is anticipated.

UV protection options for FBE coated line pipe

Many different practices are used in the coatings industry

to help reduce the effects of chalking on FBE coatings. One

popular option consists of shielding the FBE coating with a

physical cover or tarp. This option provides good protection

but can prove to be expensive and storing covers when not

in use can be inconvenient. Tarps can be difficult to utilise

over long stretches of pipe or in environments consistently

exposed to high wind.

Whitewashing the FBE coated pipe with a liquid UV

resistant coating is a less expensive option, however the

process must be completed offline of the FBE powder

application process and can prove to be very messy. In

addition, this process requires a long drying time before

the pipe can be marked for identification. If the FBE coated

pipe is stored for a great deal of time or used in above

ground application, whitewashing often has to be repeated.

Compatibility concerns also exist between whitewashing and

FBE coatings.

A simple and effective manner of building UV resistance

in coatings is using a dual layer powder coating consisting

of an FBE corrosion coat and a UV resistant top coat. The

UV resistant top coat can be applied directly after the

application of the FBE powder coating allowing for easy and

clean applications, as well as good interlayer adhesion. Nap-

Gard® Sol-Gard (PCW601S9) manufactured by Axalta Coating

Systems is a UV resistant top coat suitable for protection

over Nap-Gard single layer FBE or dual layer FBE systems.

This fast curing, thermosetting polyester coating is capable of

protecting FBE coatings from UV deterioration in both above

ground applications or during storage.

Design of Sol-Gard

For approximately two decades, dual powder FBE systems for

pipe coatings have been used in corrosion protection. Because

the epoxy resins used in most standard FBE coatings are

Bisphenol A (BisA) based, resin suppliers have limited choices

in the tailoring of resin structure and properties, especially

for UV resistance. But unlike BisA based epoxies, there are a

variety of monomer choices for polyester resins that provide

the optimal reactivity and other useful properties needed,

such as hardness, flexibility, weatherability and gloss.

FBE coating applications require certain speeds in order

to be productive, which includes a quench time of usually

less than 3 mins. To meet these requirements, the polyester

powder top coat must meet the following criteria:

)

)

High reactivity to meet application speed.

)

)

Excellent exterior durability.

)

)

Good flexibility for field bend during pipe installation.

)

)

Good adhesion to corrosion protection layer.

Application Procedure

Polyester powder top coats are not designed to be corrosion

protection coatings, and therefore should only be used in

conjunction with single-layer FBE coatings. As with dual FBE

powder systems, it is critical to follow the proper procedures

for application in order to achieve the desired coating

performance.

)

)

Cleanliness: grit blast to NACE Near-White specifications

(Swedish Standard Sa 2.5).

)

)

Profile: grit blast to angular profile 50 - 112

μ

m.

)

)

Application:

y

y

Preheat the pipe to 232 - 253˚C (450 - 488˚F).

y

y

Apply the single layer FBE or dual powder system using

electrostatic spray or flocking application.

y

y

Apply the Sol-Gard using electrostatic spray or flocking

application immediately after the FBE or dual powder

system. The basecoat must be at or above 218°C (425°F).

A separate reclaim system is required to eliminate

contamination of the FBE powder.

y

y

Water quench the pipe after allowing sufficient time

for proper cure.

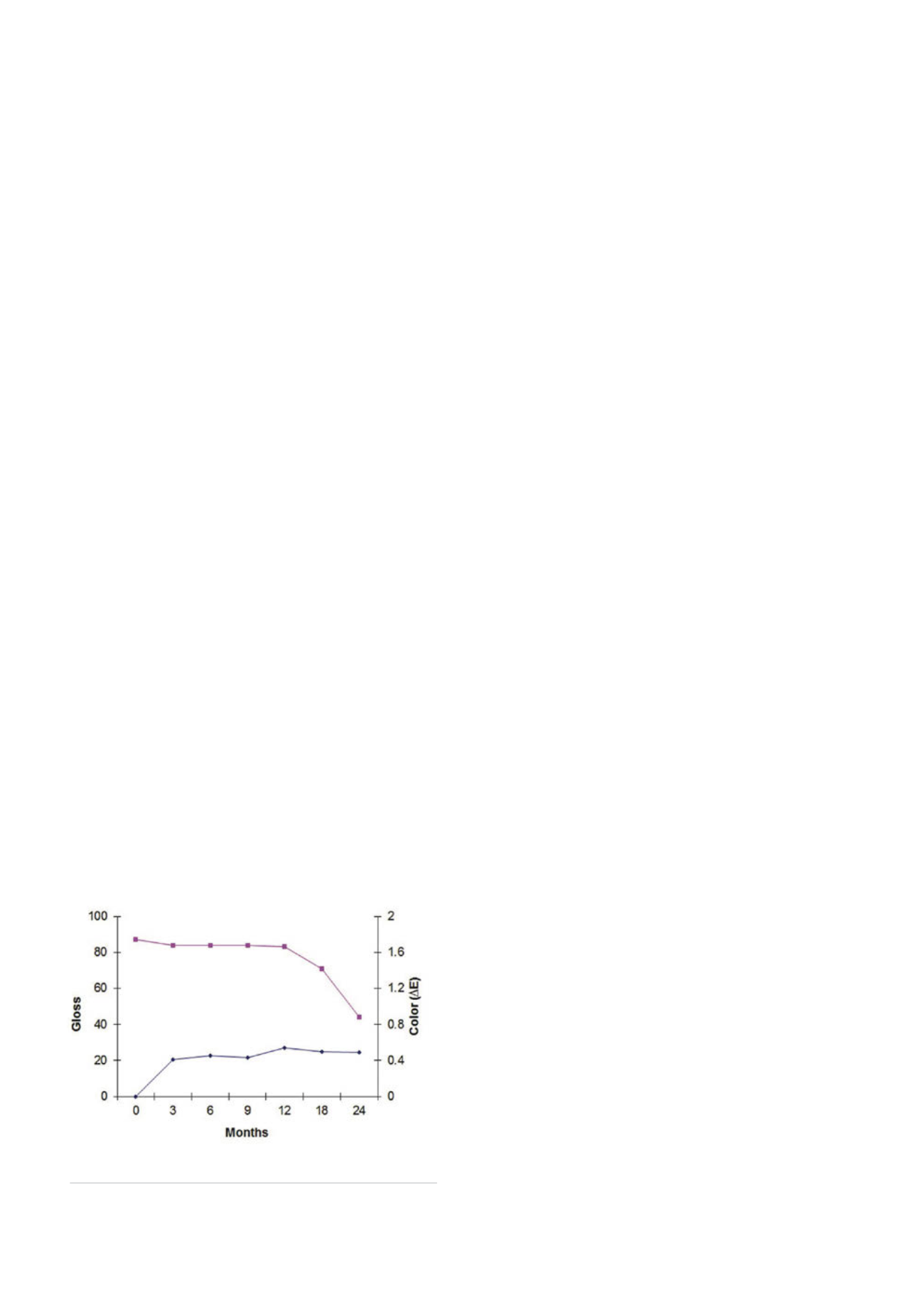

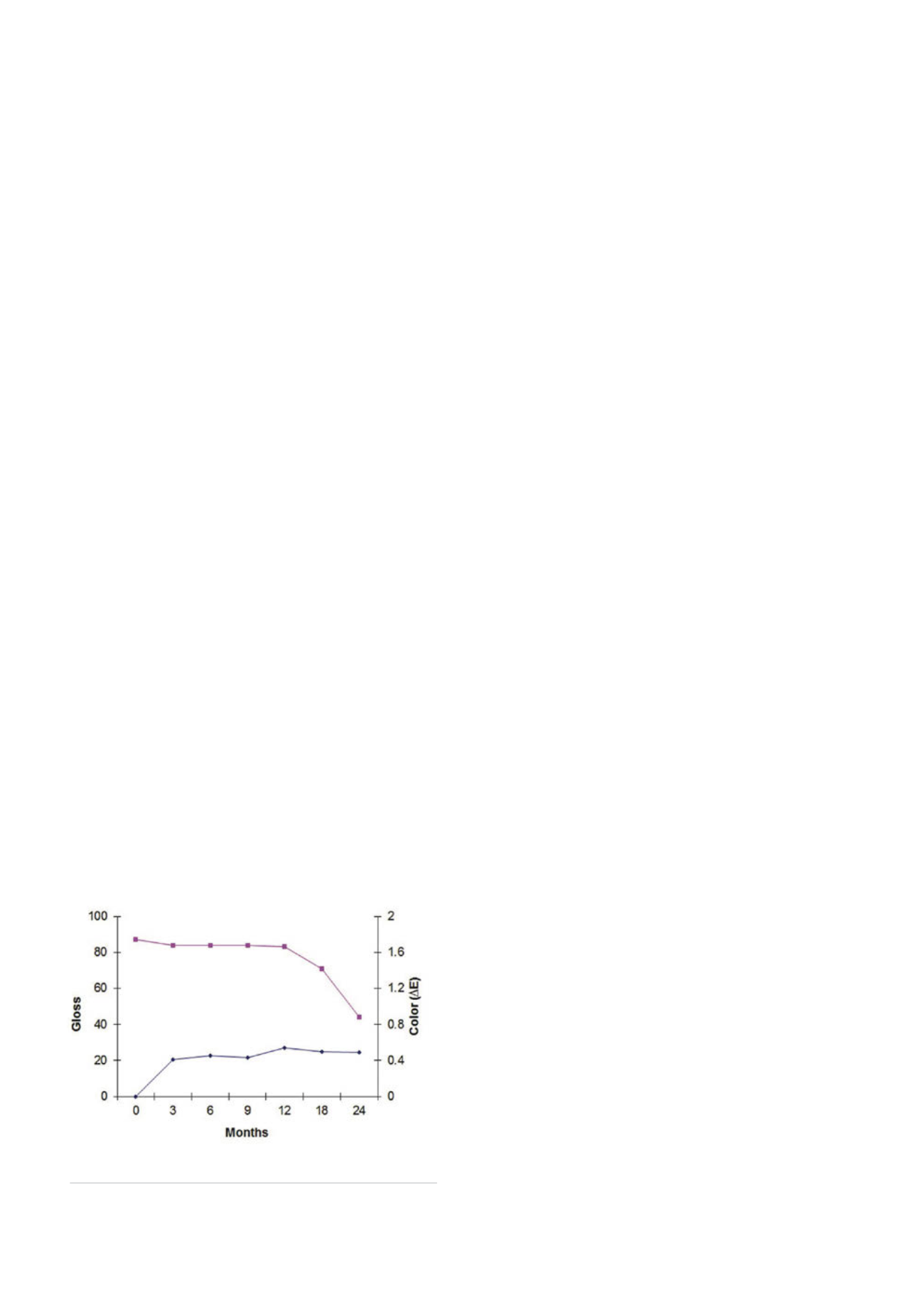

Figure 1.

Gloss and colour change after Florida weathering

exposure.

22

World Pipelines

/

FEBRUARY 2016