Having analysed the ILI and

non-destructive testing data, the

integrity engineer can use the

software to assign a repair by

selecting the type from the set of

available repair types used in their

organisation. The software allows

the user to further expand and

enhance the list of repair types,

providing further configurability.

The ILI Expert module can

also automatically assign repairs

to a set of selected defects

according to company policy.

The defect selection criteria and

repair assignment algorithms are

fully customisable and can be

created or enhanced by integrity

experts, without the involvement of IT personnel or software

developers.

A detailed set of documents for excavations and repairs are

automatically generated at the same time as repair assignment.

After the repair is assigned, information about the repair

can be sent to the company’s enterprise resource planning (ERP)

system (such as SAP, MAXIMO) or any other system used to

organise the business processes involved with physically repairing

the pipeline in the field. The ILI Expert allows the user to track

the progress of the repair implementation and its current status.

Conclusion

Being able to analyse reports generated from ILI – integrated

with other key pipeline data required for PiMS, in order to

make key decisions regarding the safe upkeep of a pipeline

network – is becoming an increasingly important part of the

pipeline integrity process.

The best integrity software should provide integrity

engineers with the right tools to work quickly with high

volumes of data, and to be able to make the right decisions

regarding the ongoing maintenance of the pipeline.

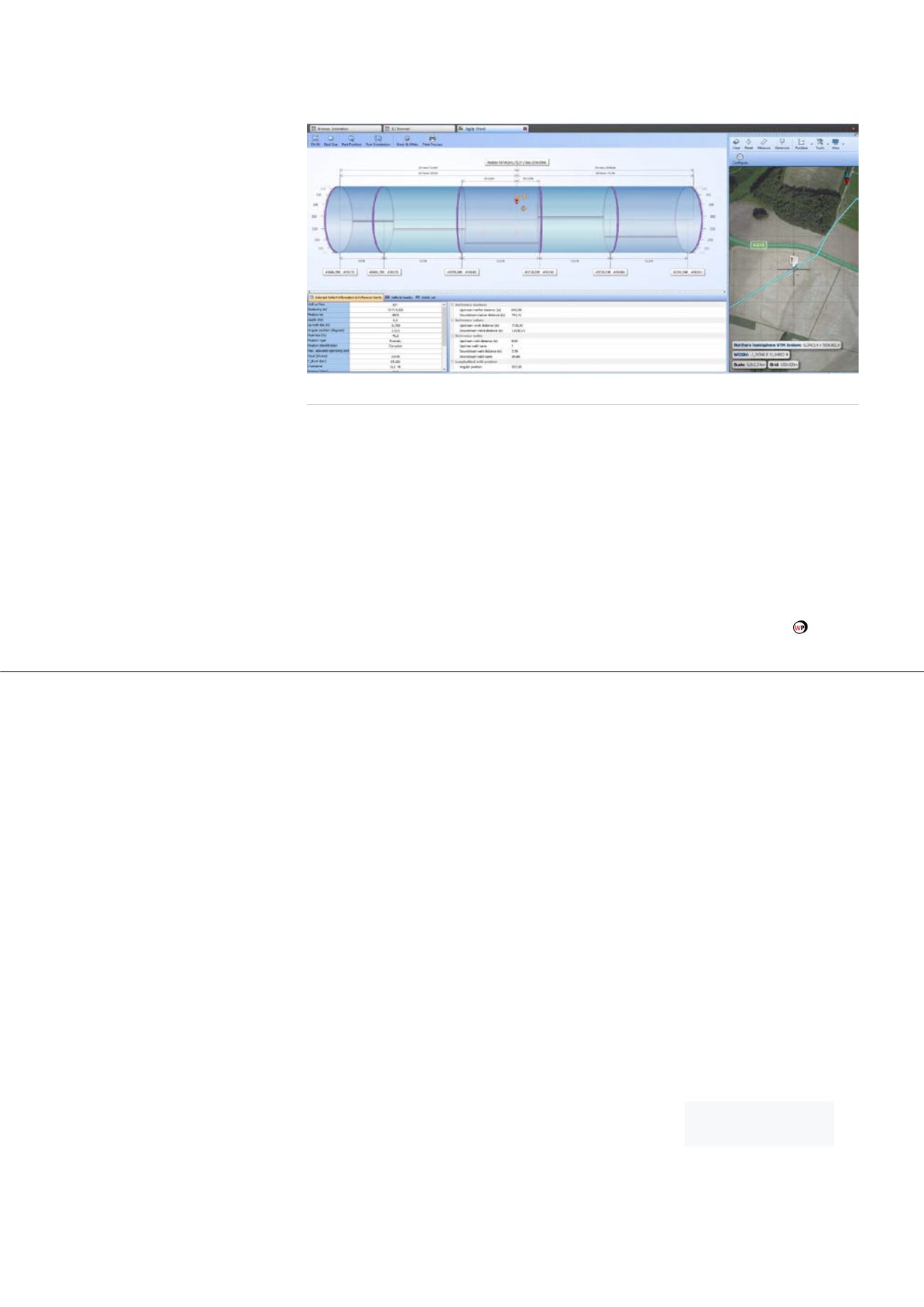

Figure 4.

Part of a dig sheet containing all the information required for an excavation.

Making the world a cleaner place...

One pipeline at a time.

™

Tel:

281-351-2749

Fax:

281-351-4658

Toll Free:

800-578-7436

Email

distributors

wanted