ODS analysis clearly identifies the vibration patterns

occurring under real life conditions, and so machinery and

structural supports can be adjusted and optimised in light of

those findings. When used as part of a proactive maintenance

schedule, particularly when this is done in partnership with an

experienced and recognised specialist in asset integrity and

performance, ODS analysis can help organisations to avoid

the threats posed by vibration-induced machinery problems,

and to make more efficient decisions around investment and

product lifecycles.

What is ODS?

ODS analysis is a means of visualising the vibration pattern

occurring in a structure. That vibration may result from the

structures own operating forces, or from forces external to it.

In ODS analysis, vibration is measured at various points and in

various directions within the structure – these are referred to

as degrees of freedom (DOFs).

Specialised software is used to convert the measurements

into appropriate formats, in particular, as animated graphic

representations of the structure being analysed. These

animations clearly show how and where the vibration is

causing problems, and to what degree. Typically, the structural

responses will be greatest at a number of specific natural or

forced frequencies where, at each frequency, the structural

deflection forms a particular mode shape (illustrated by

relative amplitudes and phases at each position on the

structure). In reality, all structural modes are happening at the

same time, however, by animating each different frequency

component of vibration separately, it is much easier for the

specialist to understand very complex data. The data is useful

for identifying a number of key factors:

)

)

Which excitation frequency produces the greatest

amplitude of vibration?

)

)

Which positions of the structure show the largest

displacement amplitudes?

)

)

Are there any positions of looseness of fixings or any

structural supports that appear to be too flexible?

)

)

Where would be the best positions to try to re-inforce the

structure to resist the observed directions and amplitudes

of vibration?

The analysis

There are four main types of ODS analysis:

)

)

Time ODS – used to investigate vibration as a function

of time, this method can visualise deflection shapes

generated by both transient and stationary signals.

)

)

Running orders ODS – used to evaluate vibration patterns

at specific orders as a function of rotational speed or

frequency.

)

)

Running modes ODS – evaluate vibration at given

frequencies as a function of rotational speed or frequency.

)

)

Frequency/spectral ODS – used to examine vibration

patterns at specified frequencies in stationary conditions.

Any item subject to ODS analysis has an almost infinite

number of DOFs that could be measured, but in practice

the number of these that are sampled during testing will

vary according to the size of the structure, the applications

and context involved. For pipework vibration assessments,

typically, vibration measurements would be taken at the

following positions: pipe bends, mid points of long spans, all

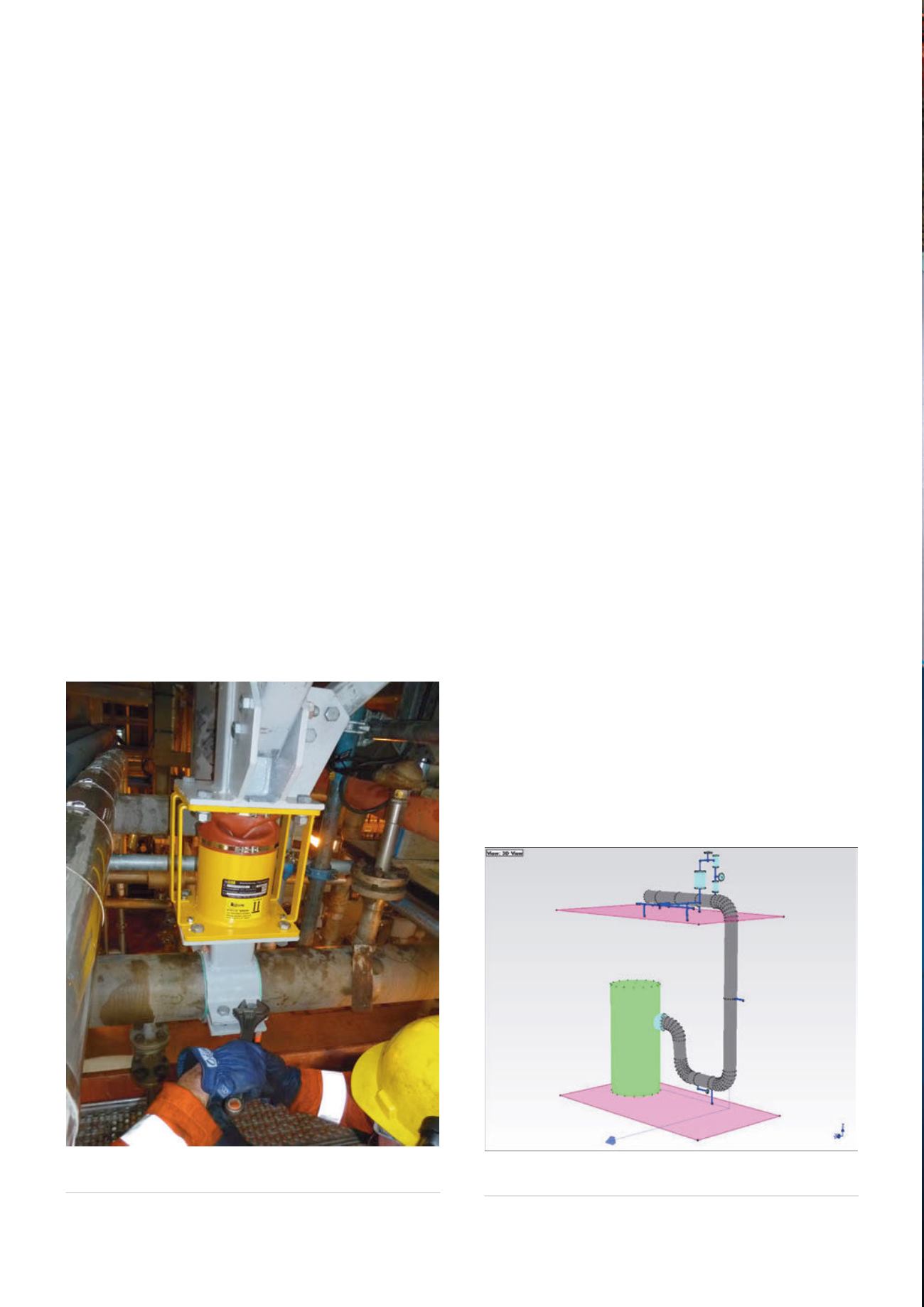

Figure 1.

Visco-elastic damper installed to prevent vibration

after ODS analysis.

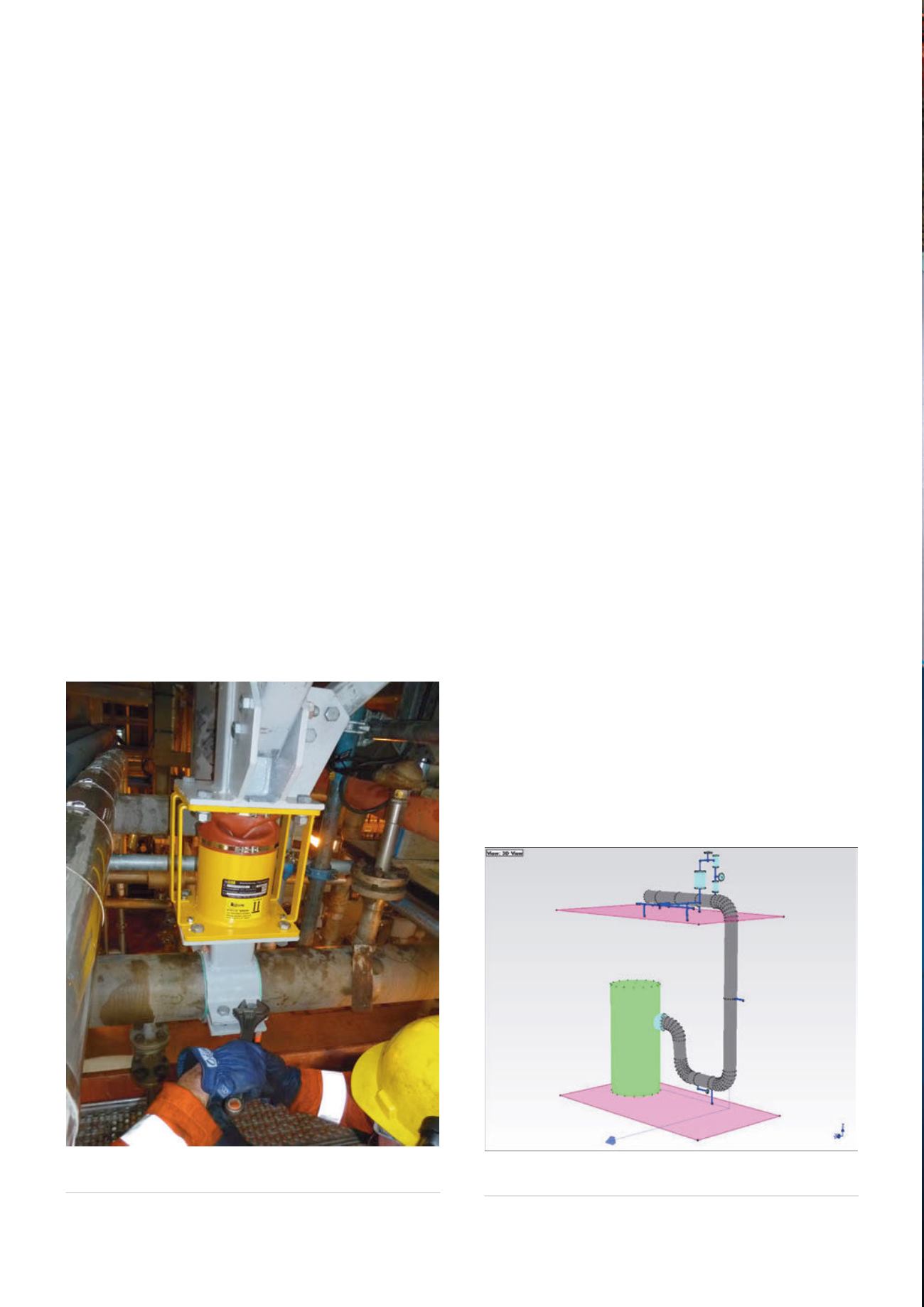

Figure 2.

ODS Plot showing baseline model of relief valve

pipework.

48

World Pipelines

/

FEBRUARY 2016