asset. Industry codes and standards are available to guide

engineers in the span assessment process, but they can be

overly conservative.

Span assessment

Jee’s engineering team has applied their expertise of

pipeline free spans to problems from all over the world.

The team uses their in-depth understanding of the

industry codes and standards and their wealth of integrity

management experience to remove undue conservatism in

free span assessments.

Coupled with regular pipeline inspection to monitor

span development, the company is often able to help

its clients avoid the need for costly remediation whilst

ensuring the continued safe operation of their assets.

Free span remediation generally takes the form of rock

placement and, considering remediation can in itself lead

to additional issues such as the formation of long

free

spans either side of the rock berm, its avoidance can greatly

simplify future integrity management and remediation

requirements.

In order to assess free span acceptability, Jee typically

adopts the approach specified in DNV-RP-F105, using a

combination of code compliant calculations and finite

element (FE) analyses as appropriate. The company’s

experience of delivering these free span assessments has

enabled them to build up a suite of validated calculation

templates and base models, which are reviewed and updated

as the standards are revised. This allows the team to turn

around free span assessments quickly, giving clients the

required information to make informed decisions on the

need for remediation and the associated timeframe such

that fitness-for-service is not compromised.

For more complex problems, such as the assessment of

free spans in pipe-in-pipe systems or bundles, the company

adopts a finite element approach in accordance with DNV-

RP-F105, ensuring that the differences in structural response,

damping and fatigue properties from a single rigid pipeline

are accounted for.

Span monitoring

The balance between compliance with the recommended

practices for free span assessment and the observed, ‘real

life’ span behaviour is a consideration that Jee not only has

experience of, but encourages the industry to adopt.

It has developed a free span monitoring system enabling

simultaneous real time recording of pipeline movement

along a free span, along with the associated water particle

velocities at the span location. The data is used to identify

if pipeline vibration is occurring at the flow velocities

predicted to cause excitation by the assessments performed.

If vibration does not occur when anticipated, the data

collected can be used to identify the areas of conservatism

in the analysis, which can then be updated accordingly.

The system comprises a number of accelerometers, a

remote power source, a data logger and current meters to

measure the local water particle velocity. This equipment

is housed in a streamlined module, which is strapped to

the spanning pipeline. The weight and positioning of the

system (at least two modules are used for each assessment)

is designed so that it minimises interference with the

pipeline response whilst enabling the acceleration of the

free span and therefore mode

of response to be identified

through comparison of the results.

Pipeline response data is logged

for an agreed period of time, after

which the data is retrieved and

downloaded for processing.

This monitoring system has

been deployed in numerous

locations worldwide and has helped

arrive at a number of interesting

conclusions. For example, the

company has found that free spans

of a significant length (over 100 m)

that industry codes had predicted

to fail imminently, were not actually

experiencing VIV. These findings had

a significant impact on the strategy

the client adopted for managing

free spans in the region.

Case study

The problem

Jee secured a contract with a major

oil and gas operator to perform a

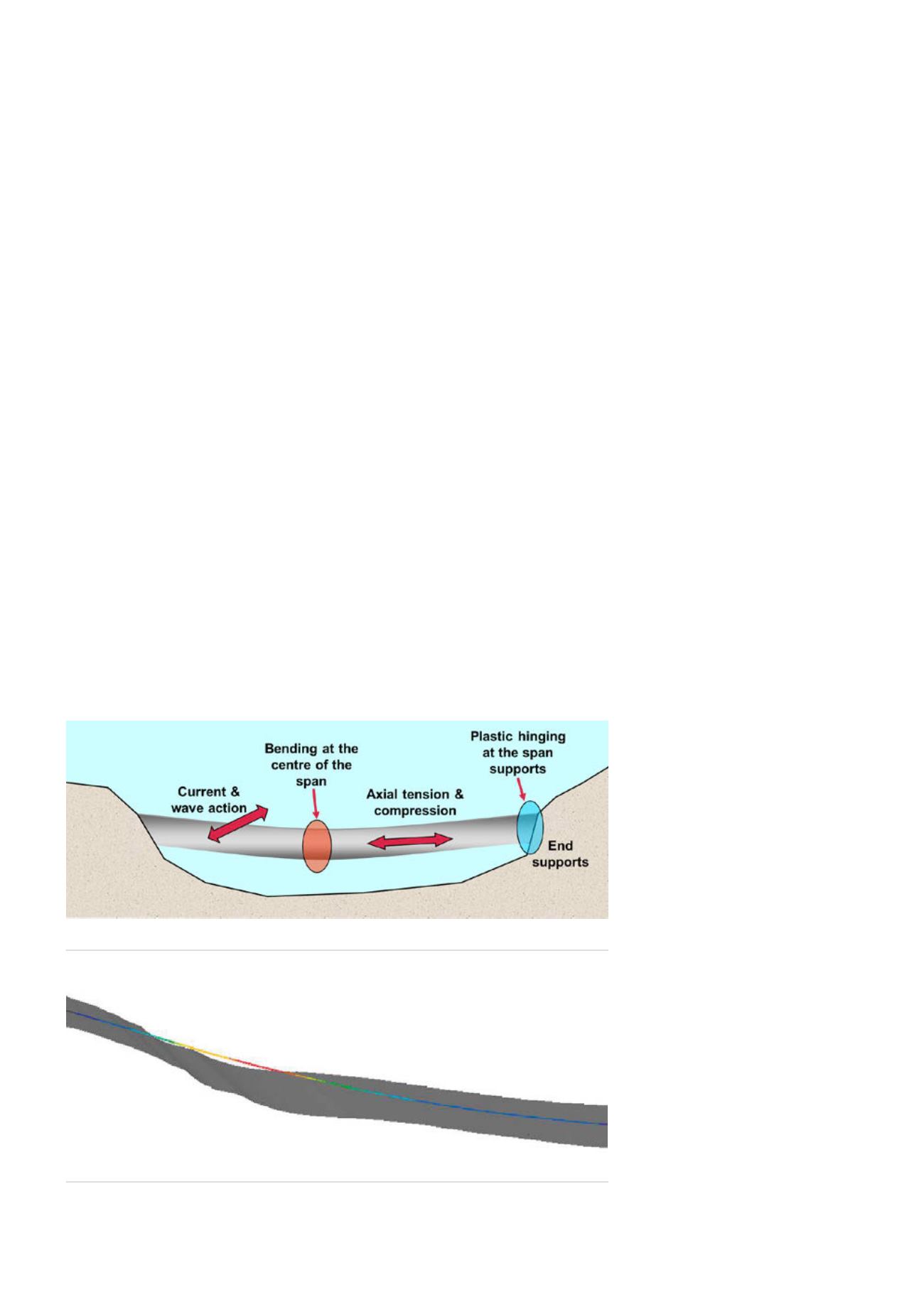

Figure 1.

Loads experienced by a freespanning pipeline.

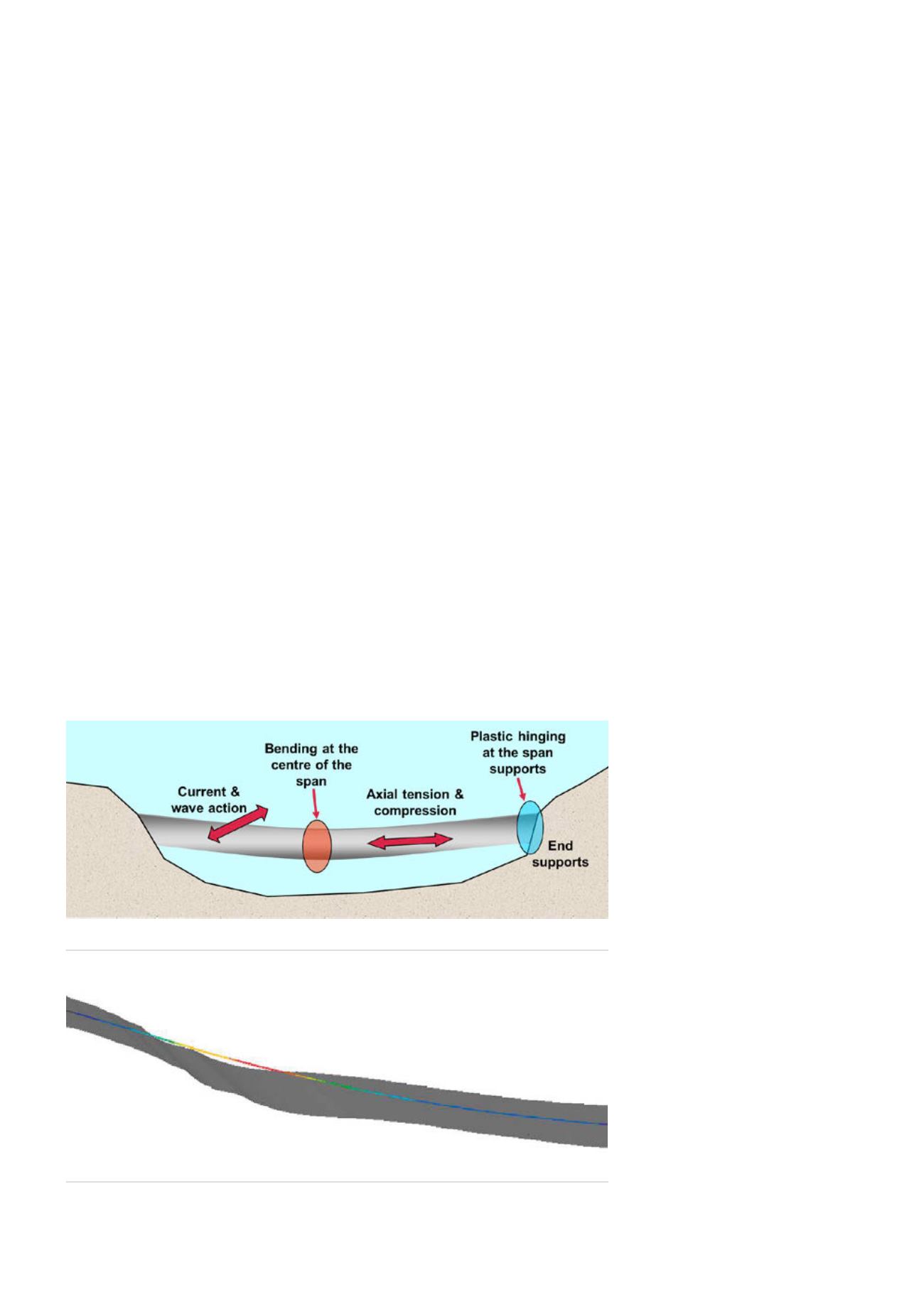

Figure 2.

FEA mode of spanning pipeline.

52

World Pipelines

/

FEBRUARY 2016