January

2016

Oilfield Technology

|

47

(Massachusetts Institute of Technology) studies on meteorological

prediction rates, errors in cyclone prediction “have a substantial

effect on the damage done to a certain area. A difference of one

hundred miles could determine whether or not people (and rigs)

are forced to evacuate. These are large distances for errors in

forecasting landfall.”

1

In the last five years the National Oceanic and

Atmospheric Administration (NOAA), one of the major players in

storm tracking, has reported an average error of 241.6 miles and

14.8 knots at just 120 hours (five days) before the cyclone hits.

Cyclones are 100 miles in diameter on average, and most rigs can

easily weather storms with sustained wind speeds at or below

60 knots. This means that weather tracking often completely

misses the mark in cyclone prediction and weatherability.

Another concern is that a vessel, not knowing the cyclone’s

path, could head off in the wrong direction and end up getting

caught on the ‘dirty’ side of the storm (where wind speeds are

higher and danger increases).

That can spell big trouble for MODUs. Moored DP vessels

require an average of five days to execute a site move. But at

five days, the accuracy of cyclone prediction is so uncertain it

often leads to unnecessary rig moves, which can cost a company

millions of dollars. This loss comes mainly from lack of drilling

time, fuel expended, and the cost of the rig and secondary

support vessels.

The new system significantly reduces transit time (T-time)

needed, saving four hours per mooring line, on average.

With generally 8 – 12 mooring lines per rig, this time adds up

significantly, reducing T-time by up to 48 hours. This reduced

time means the rig can continue drilling for longer. Plus,

since prediction accuracy increases as the cyclone gets closer

(at 48 hours average error falls to 88.7 miles and 13.3 knots

according to the same NOAA study), the rig has more time to

make an informed decision about evacuation.

2

In addition, when paired with active winching, the system

does not require the use of secondary support vessels to release

mooring lines. This can eliminate costly spot rates for AHVs,

which can run in excess of US$100 000/d.

Since DQR activation requires limited personnel involvement

on the back deck, it also poses an increased level of safety to

onboard employees. During harsh weather conditions, the back

deck of an AHV can pose a significant threat of bodily trauma and

man-overboard scenarios.

Conversely, the system also allows companies to quickly

escape a storm that had been previously predicted to miss their

vessel or has suddenly escalated in intensity. In situations like

these, a rig crew may have no choice but to cut the mooring

lines during harsh metocean conditions and hope for the best,

which places personnel and equipment in a perilous situation.

In rare cases there is not time for even this, which poses a very

significant threat to the lives of the crew onboard as well as the

vessel itself. The system mitigates this risk somewhat by allowing

the vessel to leave the danger area in a shorter window of notice.

Agreener future

When it comes to offshore drilling, one of the chief concerns

for the general population is environmental. Though it was

some years ago, the Macondo oil spill of 2010 is still fresh in the

public mind. It is the largest accidental spill in history and its

environmental effects are still being felt today.

Though the incident was not related to mooring failures, it

represents the shortcomings of oil drilling and highlights the need

for extra precautions to operators. The risk for oil companies is

not just environmental either, the Macondo incident resulted in a

price tag of more than US$42 billion in clean-up fees and a record

US$18.7 billion fine from the US government.

3

That plus the loss

of 11 priceless lives makes offshore disasters one of the most

frightening risks oil companies face.

The DQR is also a greener and more economic option for

DP vessels. Normally these vessels expend a lot of fuel, and

therefore greater pollution, to stay on location. By mooring them

instead, less fuel is required and less pollution is released into

the atmosphere.

Thus, there is quite a bit of appeal in DP moored vessels

that could be moved to escape storms instead of being forced

to weather them out. Plus having the system onboard also

means companies might have an easier time acquiring leases

to drill in more protected areas due to reduced emissions and

environmental impact. The risk of damaging surrounding subsea

infrastructure by drifting MODUs in a storm event is eliminated

with DP moored rigs on a quick release system.

Theroadahead

The new system is expected to have an immediate impact

offshore. The first eight systems are already in operation on a

semi-submersible MODU in the Gulf of Mexico.

Making drilling safer and more cost-effective is a top priority

for drilling companies. The Delmar Quick Release takes a key

step in that direction. It represents a promising beginning for

new innovations in offshore mooring, as well as a bright future of

possibilities for drilling operators.

References

1.

/

hurricanes/hurricanes-prediction.html

2.

3.

-

deepwater-horizon-oil-spill-claims-1435842739

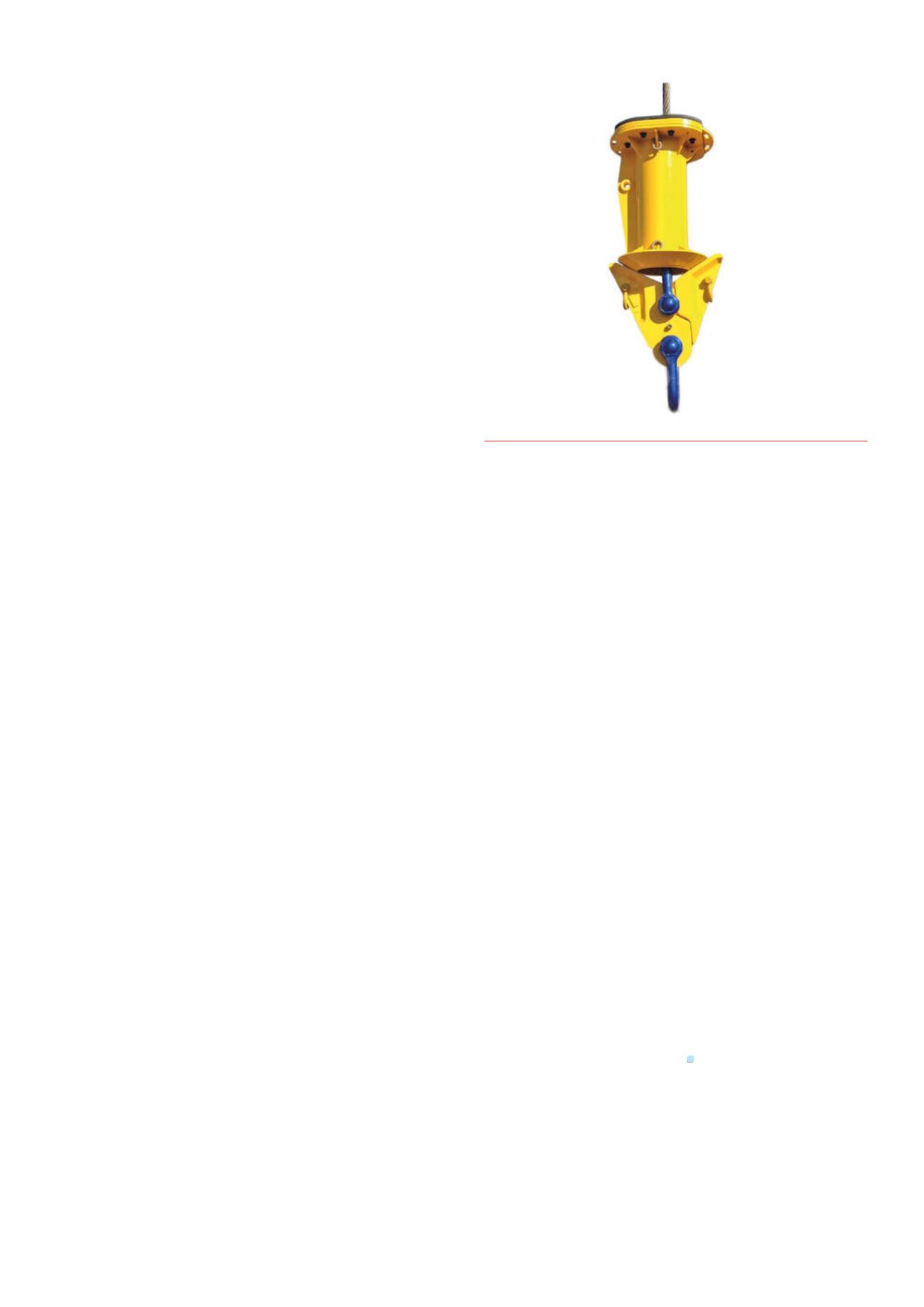

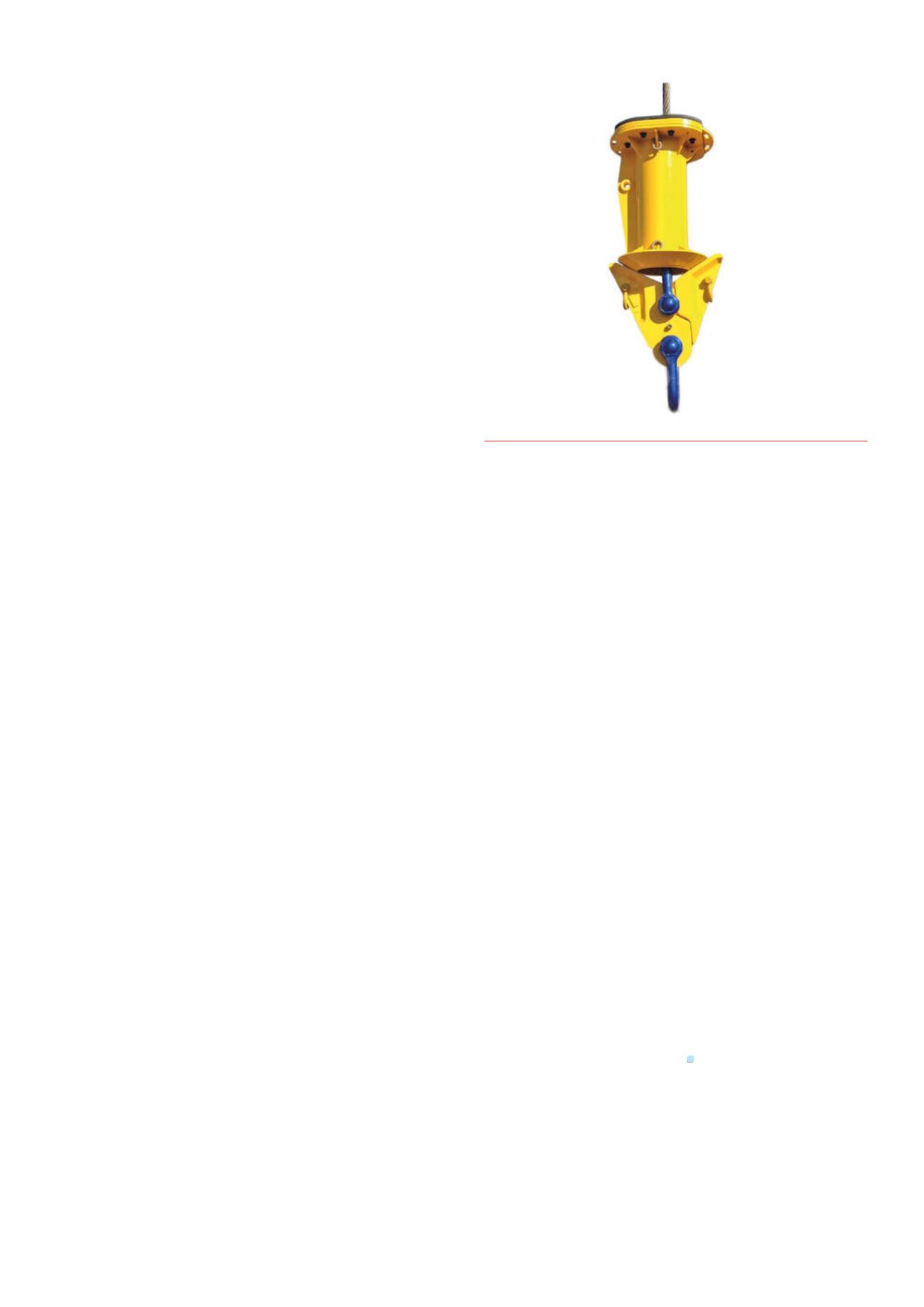

Figure 2.

Trigger sleeve andDQRassembly.