January 2016

Oilfield Technology

|

49

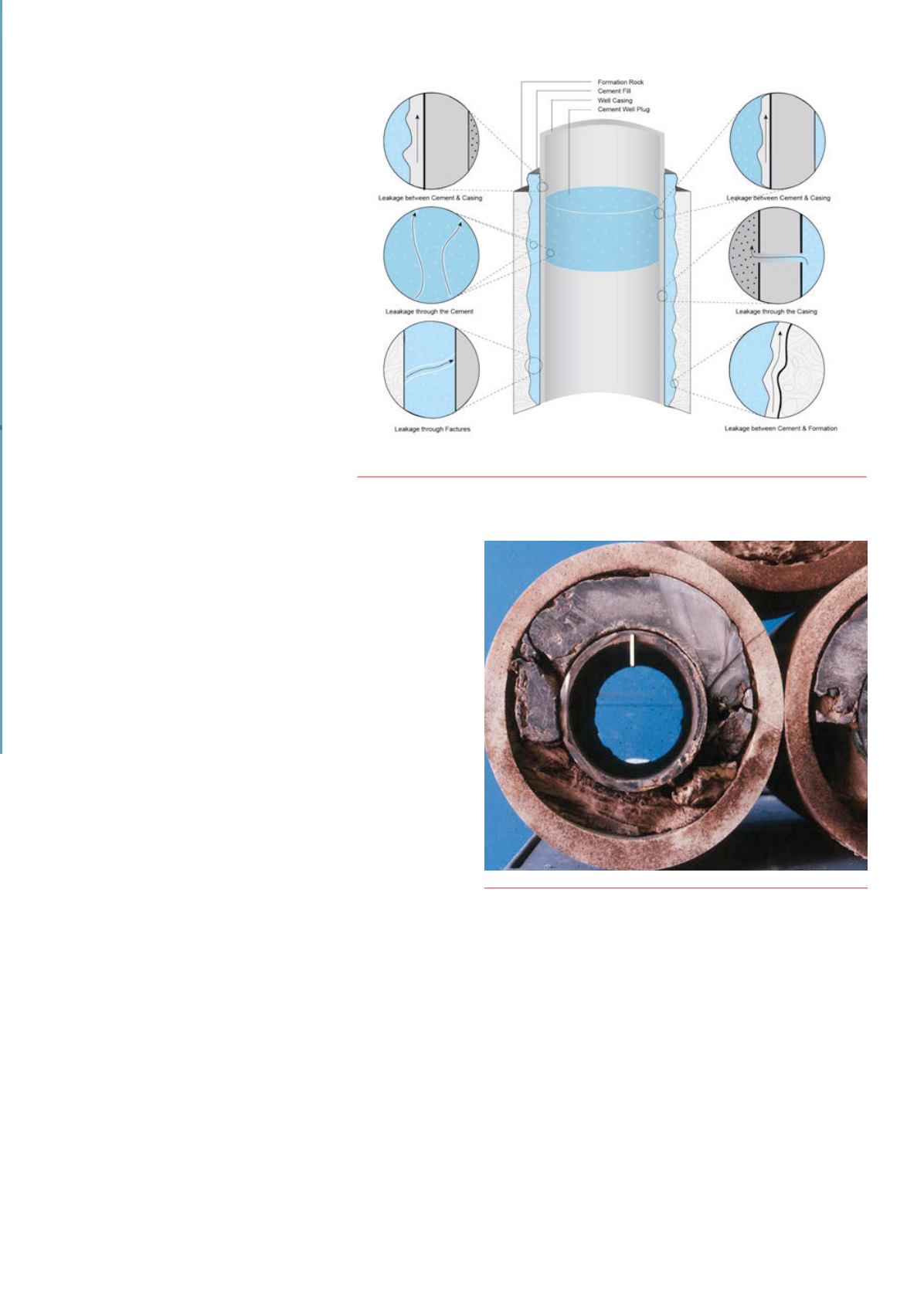

Definingtheproblem

Gas migration may occur when formation

pressure is higher than annular pressure

(Figure 1). This problem can lead to an

uncontrolled release of hydrocarbons to surface.

Contributing factors such as poor mud filter cake

removal, premature gelation and inadequate

interfacial bonding can allow gas to migrate

through the cement sheath or micro-annulus.

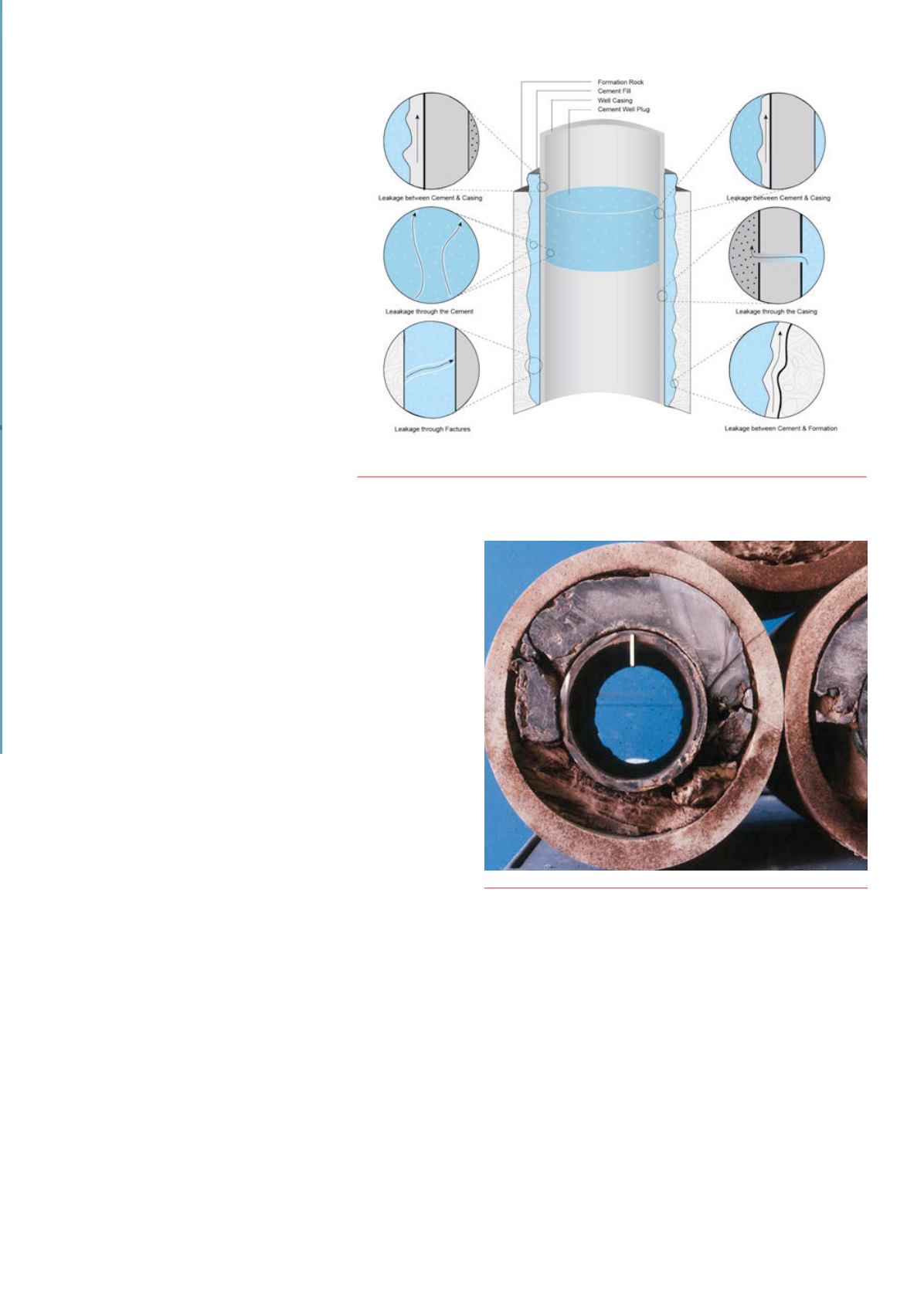

The company provides a solution for the

premature gelation which can occur during

extensive nonproductive time (NPT) during

rig up of conventional cementing equipment.

During this time period, circulation is stopped

and gelation of thixotropic drilling fluids can

occur, leading to fluid channelling and cement

losses (Figure 2).

Another negative effect of early gelation is

that it causes the slurry to become load bearing.

When part or the entire cement column becomes

load bearing, hydrostatic pressure loss can

occur, resulting in an underbalanced annulus,

which allows for early gas migration.

Often, a potential problem with cement

integrity is poor casing placement. In a perfect

scenario, casing would be perfectly centred in the

annulus in both static and dynamic states. The measure of casing

centralisation in the annulus is called stand-off (Figure 4). Due to

irregularities or tortuosity of the wellbore, pipe is not properly

centred and requires centralisers to increase stand-off. When casing

lies against the side of the wellbore, it can significantly impact the

flow of cement around the casing and create irregular cement wall

thickness (Figure 5).

Proposingthesolution

Dynamic cementation is accomplished by rotating and reciprocating

the casing while cement is being pumped. The continuous pipe

movement increases the effective volume of drilling fluid moving

in the annulus. The additional continuous movement reduces

the surface tension between the drilling fluids and the casing and

between the drilling fluids and the formation wall. It also helps

to break up cutting bridges that can occur and allows for drilling

cuttings and drilling fluids to be pumped more easily out of the

wellbore.

Continuous rotation of the casing string reduces the effects

of early gelation, ensuring an overbalanced annulus, thereby

mitigating early gas migration. To make continuous rotation

possible, the cement swivel is placed between the casing running

tool (CRT) and the top drive. The cement swivel performs the

same function as a conventional cement head, except it has the

additional benefit of allowing an operator to commence cementing

operations almost immediately after the casing has been run. This

saves the rig hours of time that traditionally would have been spent

rigging up a conventional cement head system. As the cement

swivel is fully rigged up to the CRT, the casing drive system (CDS),

before arrival on site, there is no additional rig up time required

for the sub (Figure 6). An anti-rotating bracket (ARB) is used to

hold the swivel body secure and prevent rotation of the sub during

operation. The cement line from the pump truck is connected to the

side-entry port of the cement swivel.

Rotation of casing also ensures the cement is circulated

completely around the casing, thus reducing the chances for thin

cement sections and leading to better zonal isolation. Casing

movement and good centralisation leads to the ultimate goal of

properly centralised casing with full circumferential cementing

(Figure 3).

Casestudiesand industryacceptance

Casestudyone

Canacol Energy, in conjunction with Tesco Corporation, has

performed a number cementing jobs using dynamic cementation

techniques. These joint projects were performed in Colombia

Figure 1.

This graphic demonstrates the variousways inwhich fluid or gasmigration can occur

as a result of an inadequate cement job.

Figure 2.

A cross section of casingand cement after a trial operation is

performedwithout rotationduring cementation. It is clear that almost

40%of themud in the annuluswas not displaceddue to gel strength

anddehydration. Rotationduring cementationwould have kept the

mudmovingby exertingmechanical energy downhole to break the gel

strength.