January 2016

Oilfield Technology |

53

that is a hybridised version of a double shoulder

connection and the gas tight connection from a

drill-pipe-riser. Qualification of the new product

was performed on the most critical sizes and

involved industry standard physical testing

including make-and-break, overtorque, combined

loading and fatigue testing. This connection

is qualified to 30 000 psi internal pressure and

25 000 psi external pressure.

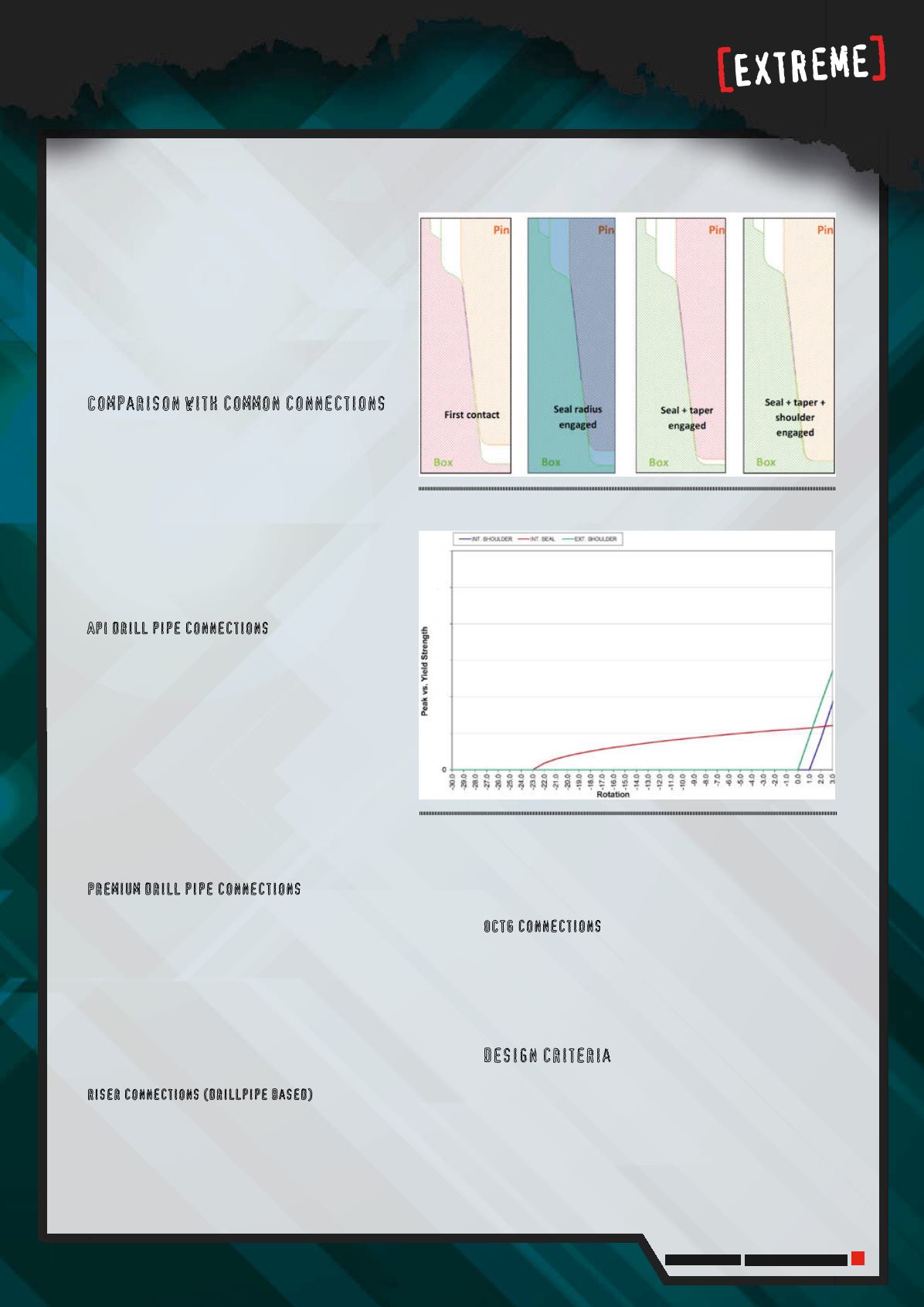

Comparison with common connections

The primary criteria for developing a gas tight

connection for deepwater operations included safety,

ease of use, and robustness.

In today’s market, available connections – such as

standard API, premium double shoulder connections,

drillpipe risers and OCTG based connections – only

fulfil some of the above criteria.

Based on these three criteria, below is a

brief comparison and summary of the existing

connections:

API drill pipe connections

API connections do not offer gas tight capability

and thus can potentially create health, safety and

environment (HSE) hazards, especially for demanding

applications such as deepwater stimulation

operations. API connectors have been designed to

be extremely robust and the threads and sealing

faces have low sensitivity to galling to resist harsh

drilling practices. With robustness comes fatigue

resistance. Although this type of connection is the

right fit for a lot of drilling operations, it can be risky

for completions and other technically challenging

applications.

Premium drill pipe connections

For more demanding applications, double shoulder

connections are designed to provide improved performance

while drilling, compared to API connections, primary

improvements are based on mechanical performances. They

are easy to use and as robust as API drilling connections.

Though this type of connection has been used for drilling

operations and some completions applications, gas tight

performance would still be inadequate for the more

challenging offshore hydraulic fracturing operations.

Riser connections (drillpipe based)

These products are specifically designed to be used in

work over/intervention/completions operations, hence

these products have been designed with excellent fatigue

resistance characteristics and can have gas tight ratings up

to 10 000 psi. The primary restriction of these products is

that they provide limited flexibility since they are designed

for completions operations.

OCTG connections

These connections are very application specific, and can be

more sensitive to galling on the thread and seal areas, which

mandates cautious handling techniques. These connectors

can be used for deepwater applications and criteria for

selection really depend on the preferred completion design.

Design criteria

Primary objectives for the development team when working

on this connection was to design and qualify a connector

with a minimum gas tight rating of 20 000 psi, offers the

ability to be handled like a drilling product and is robust by

design.

The already-existing double shoulder drilling connection

provided the foundation for such development and this

Figure 1.

Seal engagement andmake-upprocess.

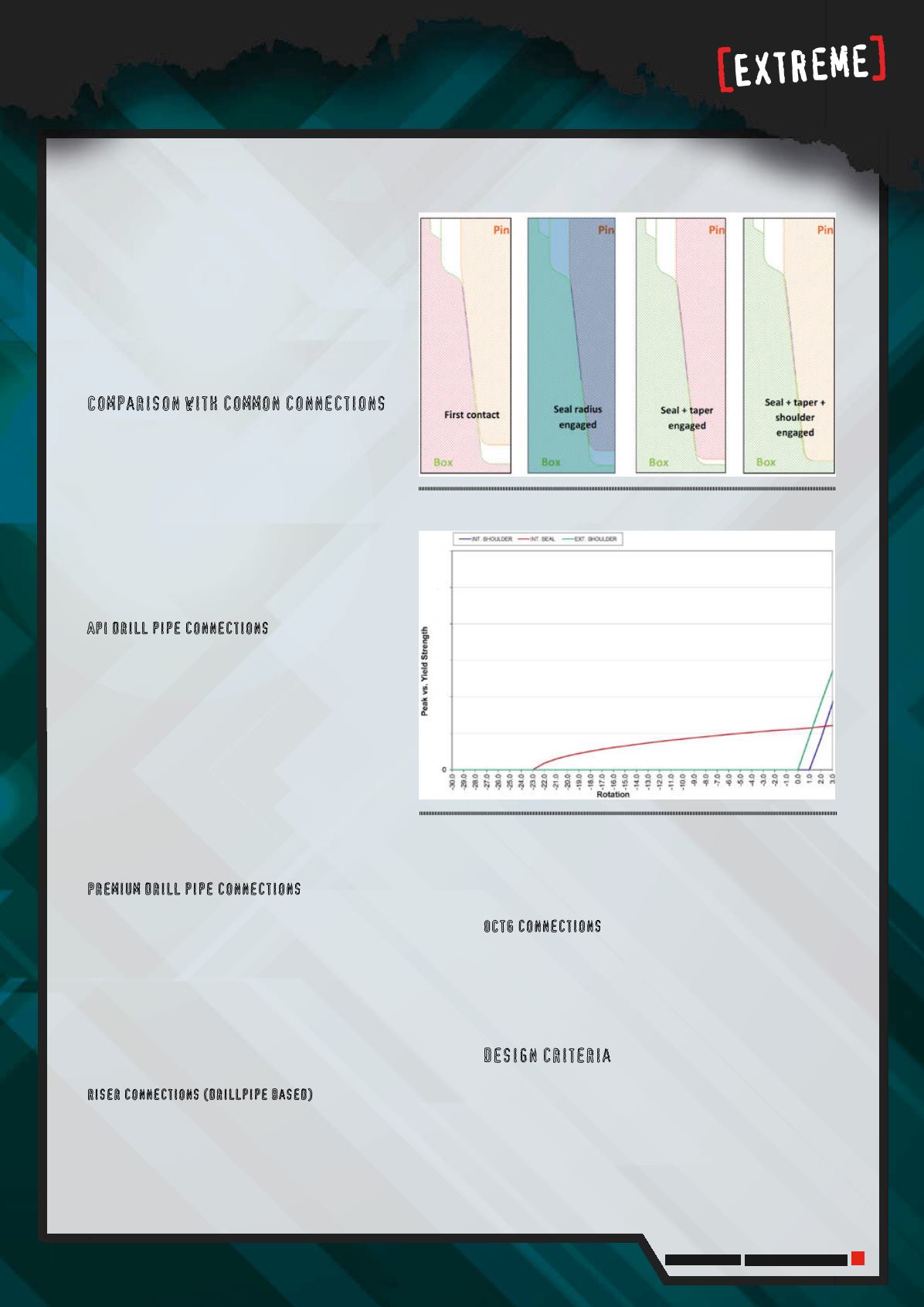

Figure 2.

Longmake-up curve (FEA).