56

|

Oilfield Technology

January

2016

As a result of the design criteria and qualification

process, a gas tight connection with metal-to-metal

technology was developed and qualified for deepwater

drilling and stimulation applications.

Sour service

It is well known that H

2

S is hazardous to human health,

living organisms, and more generally to the environment.

Historically, this is the reason wells containing sour gas

were often carefully plugged and abandoned. Steel tubular

products, such as drill pipe, may be exposed to hydrogen

sulfide (H

2

S) during drilling operations in the event well

control loss, or if the drill pipe is used with under-balanced

drilling techniques. When one or more factors are combined,

this contact can lead to a crack initiation that can propagate

and lead to catastrophic failure, and this even with stresses

largely below the yield limit of the steel.

The combination of tubular failures due to sulfide stress

cracking (SSC) and rising HSE concerns when dealing with

sour gas have led the industry to develop new drill pipe

grades with enhanced resistance to SSC.

Due to the increased demand of domestic gas in different

parts of the world, some highly sour oil and gas reservoirs

are being explored with H

2

S content beyond what could have

been imagined a decade ago. In order to explore, appraise

and develop these new fields, which often combine sour and

deep/complex well profiles, significant safety challenges need

to be overcome, including maintaining drill pipe integrity.

Drilling operations in sour wells are more associated with

complex well profiles, such as deep reservoirs or extended

reach wells. The use of high strength drill pipe is essential to

achieve such drilling objectives. However it does represent

significant technical challenges in terms of drill pipe integrity

and operational safety with the current high strength grades

available on the market. Because higher strength is generally

detrimental to SSC, innovative chemistries and new heat

treatment processes are needed to push Sour Service

material limits even further. Vallourec Drilling Products

developed the first high strength sour service grades in 2013

(VM-120 DP MS and VM-120 DP S), which are being used in

the North Sea and the Middle East.

Also, the new challenges associated with the particularly

sour fields require new highly engineered drill string

solutions in order to increase the safety margin related to

SSC failure risks, especially in the upset and the welded

zones. The drill pipe has long been used with tool joints and

tubes fulfilling separate criteria for sour service as defined

by the IRP Volume 1 (Canadian standard). Both the upset

area and the friction weld present some challenges for

preserving SSC resistance due to some metallurgical factors

such as heterogeneous microstructure, different chemical

compositions between the tool joint and the pipe body and

high hardness values close to the weld line. Steel grades with

enhanced H

2

S resistance in the weld and upset areas have

been developed (VM-95 DP SS+ and VM-105 DP SS+), and the

first string is currently being used in Brazil for workover and

intervention purposes.

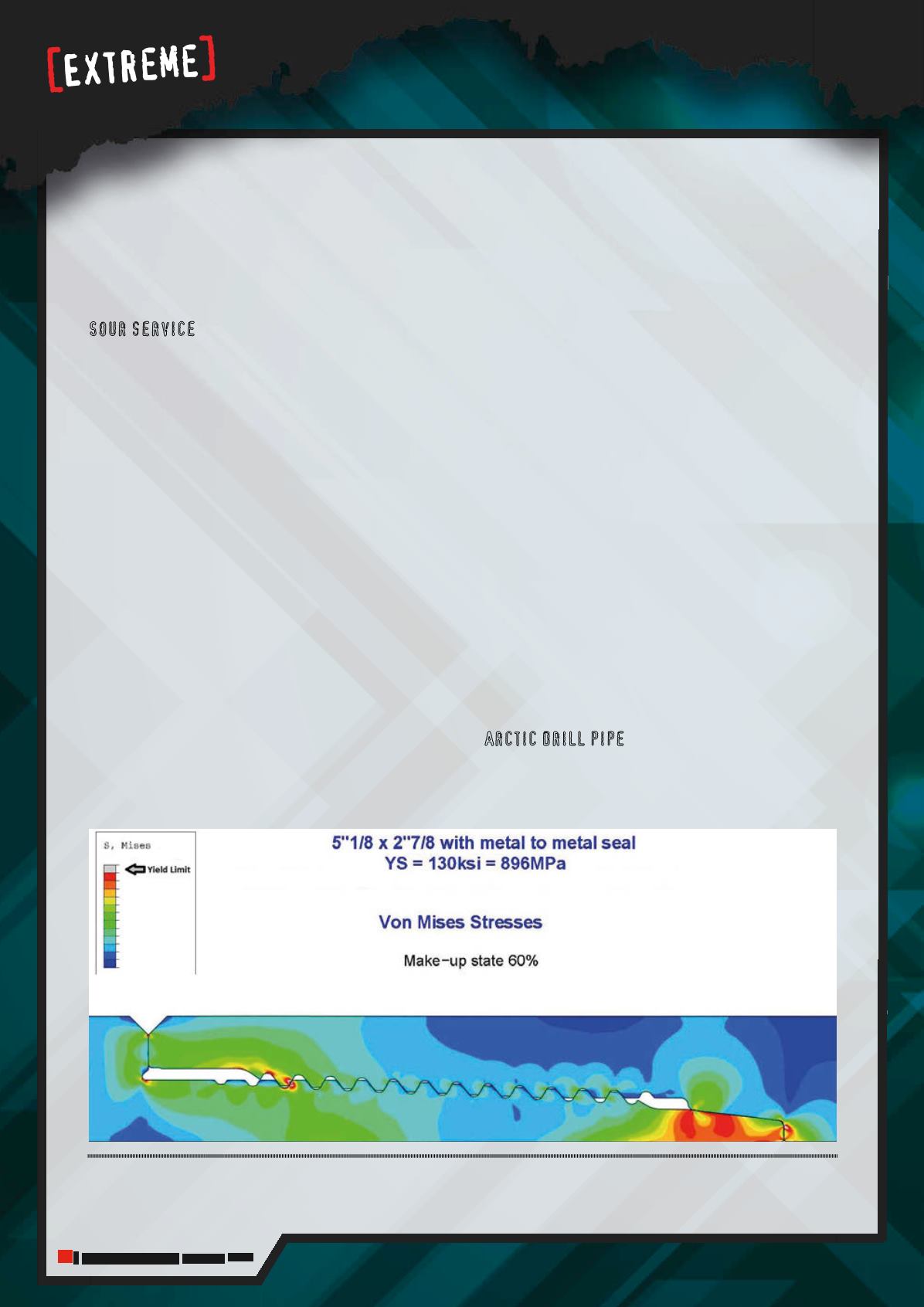

Arctic drill pipe

The evolution of the industry towards Arctic environments

has driven the development of more suitable drillstring

solutions adapted to such extreme conditions. Typically, the

Figure 6.

Finite element analysis (FEA) –Next generationgas tight connection 39: 5⅛ in. x 2

⅞

in. – Grade 130 ksi.